Polypropylene composition and preparation method thereof

A technology of polypropylene composition and polypropylene, applied in the field of polypropylene composition, can solve problems such as easy agglomeration, poor dispersion effect, poor performance of nano-polypropylene, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

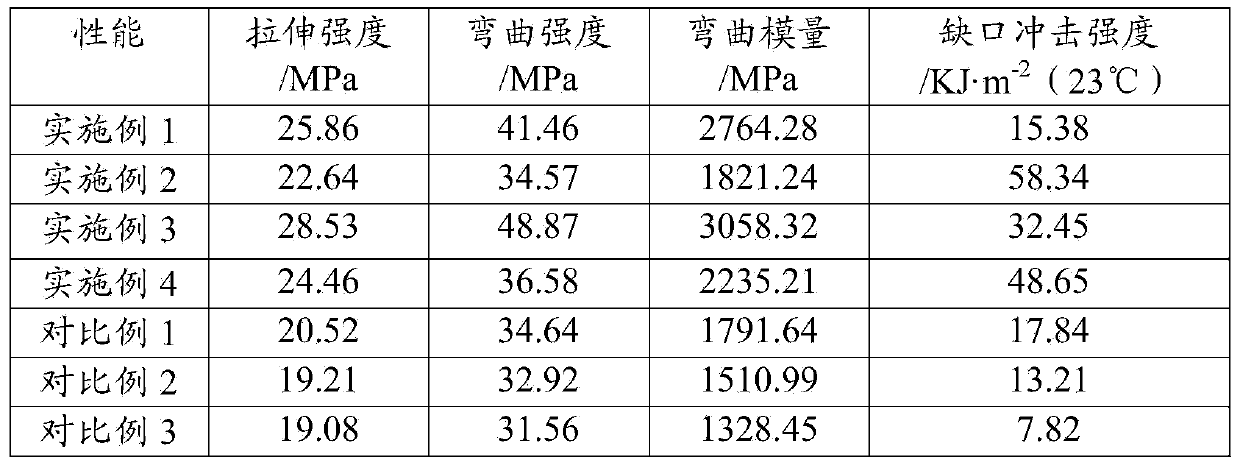

Examples

preparation example Construction

[0035] In the preparation method of the above-mentioned embodiment, especially in step S01, the nano-filler is treated with a modifier to change the polarity of the surface of the nano-filler from hydrophilic to lipophilic, which improves the phase between the nano-filler and the second polypropylene. Capacitance, thereby improving the overall performance of the nano-polypropylene composition.

[0036] In the preparation method of the above-mentioned embodiment, especially in step S03, the method of phase transfer is adopted to uniformly transfer the nanofiller from the solvent to the second polypropylene, so that the uniform dispersion of the nanofiller in the second polypropylene is realized, thereby It is easy to obtain a nano-polypropylene composition with high rigidity and toughness balance.

[0037] Specifically, in step S01, the mass ratio of the nanofiller to the solvent is 5-50:100, the dispersion time is 0.5-20 h, and the solvent is one or more of deionized water, ab...

Embodiment 1

[0045] Step S01: Preparation of Nanofiller Dispersion

[0046] Add 10 kg of nano-titanium oxide into 200 kg of deionized water, respectively use a homogenizer and ultrasonic treatment for 0.5 h to obtain a uniformly dispersed nano-titanium oxide dispersion.

[0047] Step S02: Preparation of modified nano-titanium oxide dispersion

[0048] Add 20g of titanate coupling agent to the nano-titanium oxide dispersion, react at a constant temperature of 100°C for 0.5h, and return the volatilized solvent to the reaction system of titanate coupling agent and nano-titanium oxide dispersion after condensation , the modified nano-titanium oxide dispersion was obtained.

[0049] Step S03: Preparation of nanofiller dispersion based on the second polypropylene

[0050] 90kg of high melting index polypropylene (i.e. the second polypropylene, the melting index of the second polypropylene at a temperature of 230°C and a load of 2.16kg is greater than 100g / min), 0.05kg of antioxidant 1010, 0.05kg...

Embodiment 2

[0056] Step S01: Preparation of Nanofiller Dispersion

[0057] Add 80kg of nano-silica to 160kg of acetone, and use a homogenizer and ultrasonic treatment respectively for 2 hours to obtain a uniformly dispersed nano-silica dispersion.

[0058] Step S02: Preparation of Modified Nano Filler Dispersion Liquid

[0059] Add 1.6kg of aluminate coupling agent to the nano-silicon oxide dispersion, and react at a constant temperature of 50°C for 4 hours, and the volatilized solvent will return to the reaction system of the aluminate coupling agent and the nano-silicon oxide dispersion after condensation In the process, a modified nano-silica dispersion was obtained.

[0060] Step S03: Preparation of nanofiller dispersion based on the second polypropylene

[0061] 20kg of high melting index polypropylene (i.e. the second polypropylene whose melting index is greater than 100g / min at a temperature of 230°C and a load of 2.16kg), 0.2kg of antioxidant 1010, 0.4 of antioxidant 168 , 0.5k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com