Methods and apparatus for a rugged mobile device housing

a mobile device and rugged technology, applied in the field of mobile device housings, can solve the problems of occupying a significant amount of space, requiring additional internal components or over-molded, and requiring wear-resistant plastics, so as to achieve high impact resistance, reduce deflection, and reduce the effect of bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

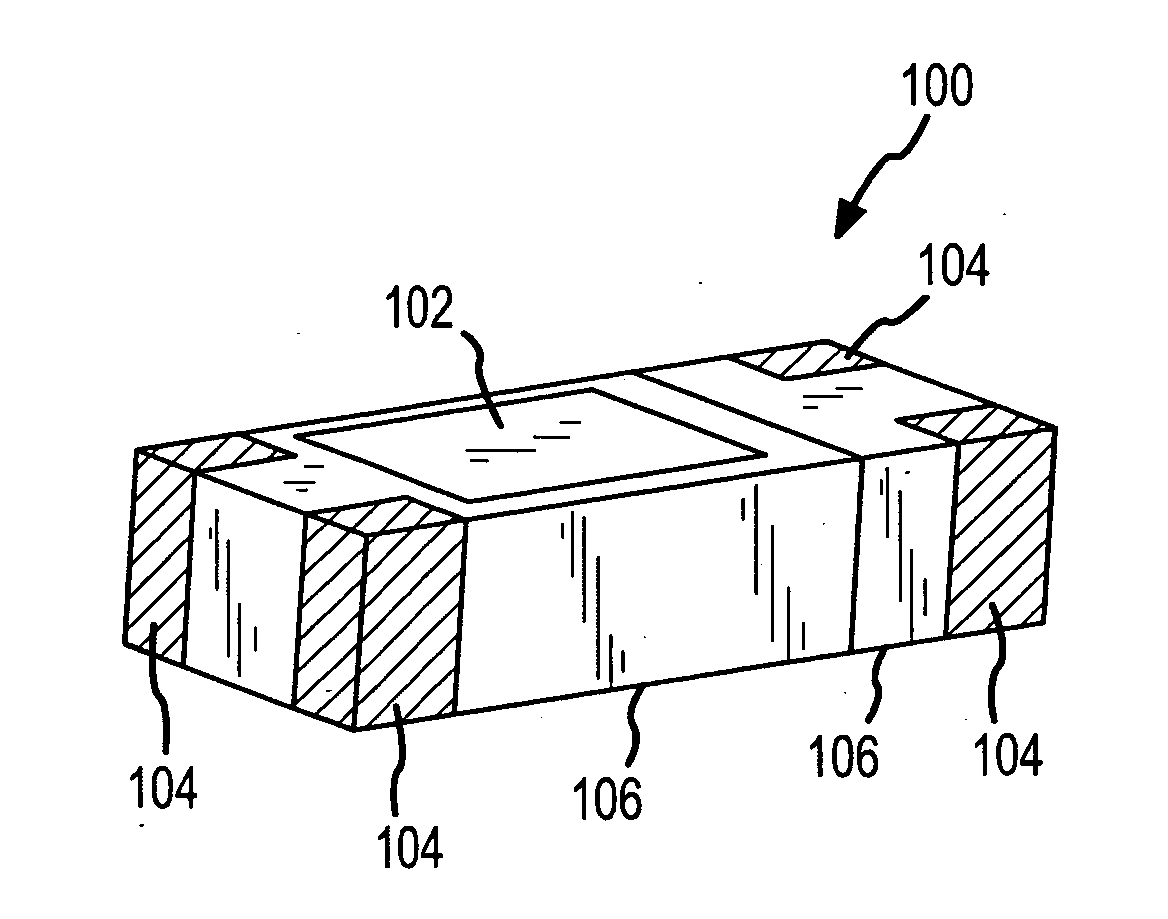

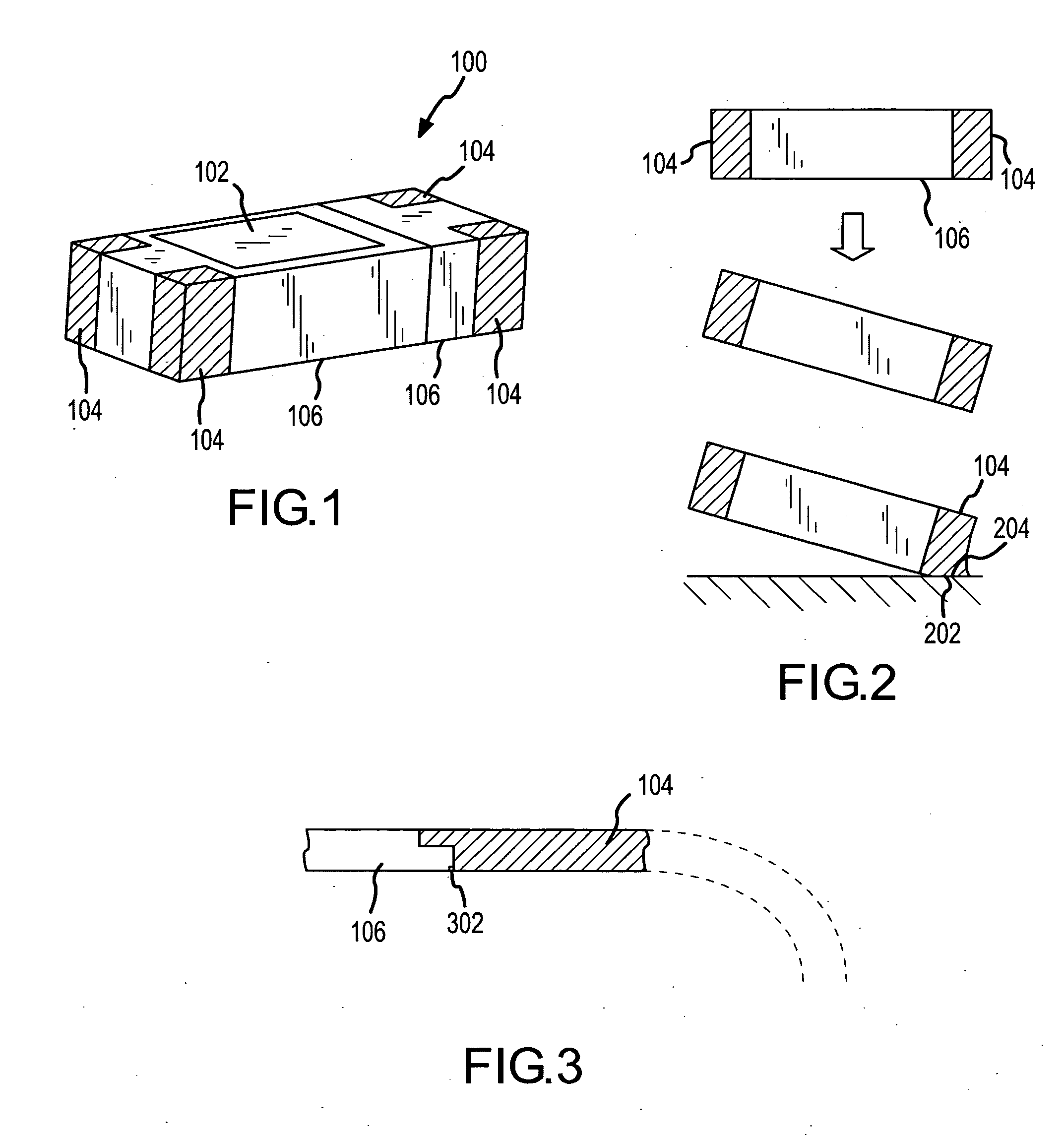

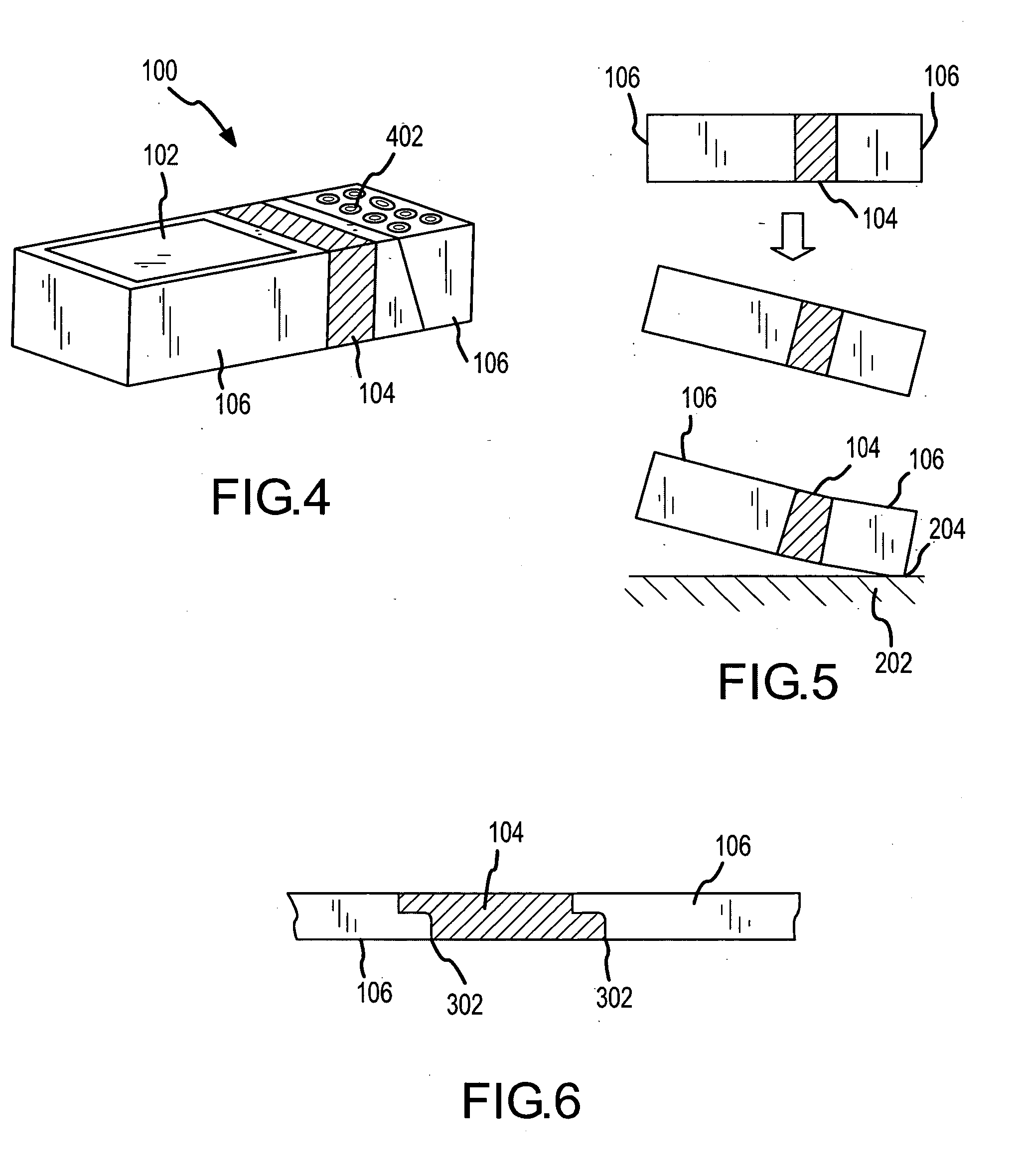

[0028]FIG. 4 presents a housing 100 for protecting a component 102. In this embodiment, a structure 104 comprising the first material is provided in a middle region of housing 100, while structures 106 are provided on one or more ends of the housing. In the illustrated embodiment, corresponding roughly to a conventional cellular phone configuration, a keyboard 402 is illustrated within one of the structures 106, and a component 102 (e.g., a display) is illustrated within the opposite structure 106. As shown in FIG. 5, a typical impact event would involve collision of the high-stiffness plastic structure 206 at a corner or edge 204, allowing central structure 104 to absorb the energy through elastic deformation. FIG. 6 depicts chemical bonding of stiff skeletal structures 106 (second material) to the sides of flexible center 104 (first material).

third embodiment

[0029]FIG. 7 presents a housing 100 that includes a projecting handle 702, a main body 704 (comprising one or more regions 106), and a hinge region defined by structure 104. Such an embodiment might correspond, for example, to a barcode scanner or other device that typically has a handle. Referring to FIG. 8, during a typical impact event, projecting handle 702 will impact at a point 204, allowing structure 104 to elastically deform, while structures 106 protect the attached components. As shown in FIG. 9, structures 106 form a stiff skeleton bonded to structure 104.

[0030] In general, the design principles set forth above may be used to develop ruggedized housings for any suitable application, while obviating the need for additional stiff internal structures. The first step, once the overall size and shape of the desired housing is determined, involves identifying which area or areas of the housing are capable of tolerating deflection (e.g., bending, twisting, etc.), and which canno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com