Residential building system with cast-in-situ beam columns and prefabricated sandwich concrete wall panels and construction method

A technology of cast-in-place beams and columns and residential buildings, which is applied in the direction of buildings, building components, building types, etc. It can solve the problems of large shrinkage of cement mortar, easy loosening and deformation, and weak splicing between meshes, so as to improve the bearing capacity and improve the overall The effect of sex and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

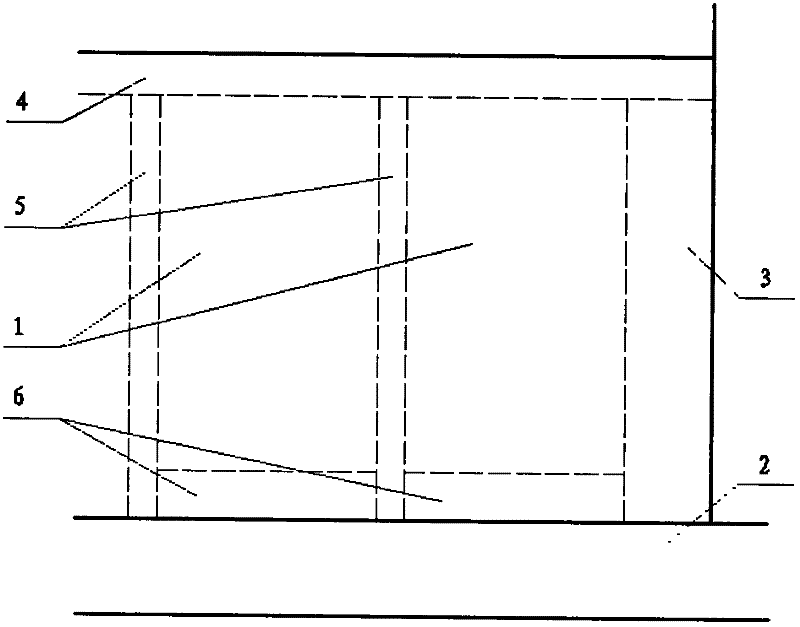

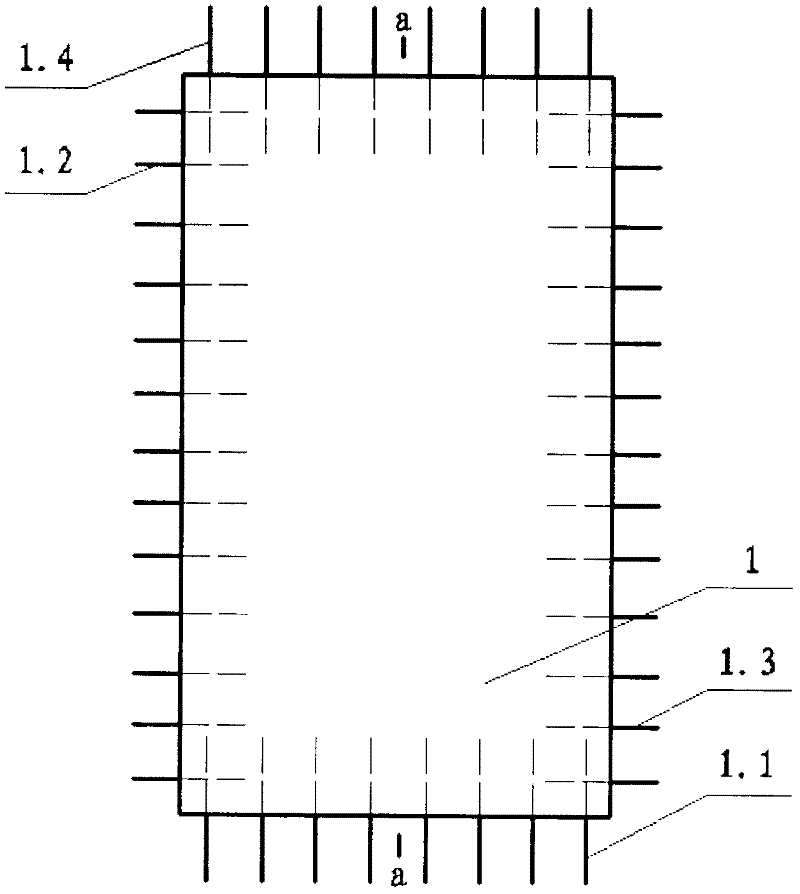

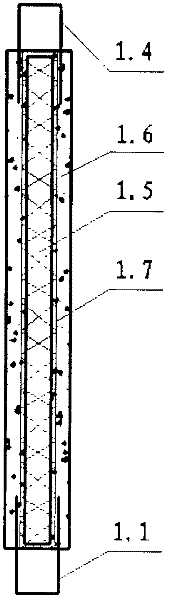

[0022] The invention provides a construction method for a residential building system of cast-in-place beam-column prefabricated sandwich concrete wall panels. Figure 1-6 Be explained. The construction process of the vertical load-bearing structure of each floor of the system is as follows: the prefabricated sandwich concrete wall panels 1 are installed in place on the lower beam / foundation 2 cast on site, so that the prefabricated sandwich concrete wall panels are connected Leave a certain vertical interval at the vertical interval and the corner of the wall to install the clamping mold, block the clamping mold, and then pour concrete on site, preferably pouring C25 concrete, so that the plate formed at the vertical interval The intermediate connecting column 5 is consolidated into one with the prefabricated sandwich concrete wall panel and the cast-in-place corner column 3 . The corner posts may include exterior corner posts and interior corner posts.

[0023] Preferably,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com