Method for preparation of multi-layer flexible circuit board

A flexible circuit board, conductive circuit technology, applied in multilayer circuit manufacturing, printed circuit manufacturing, printed circuit and other directions, can solve the problems of short circuit or open circuit, long process time, unstable flexible circuit board quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

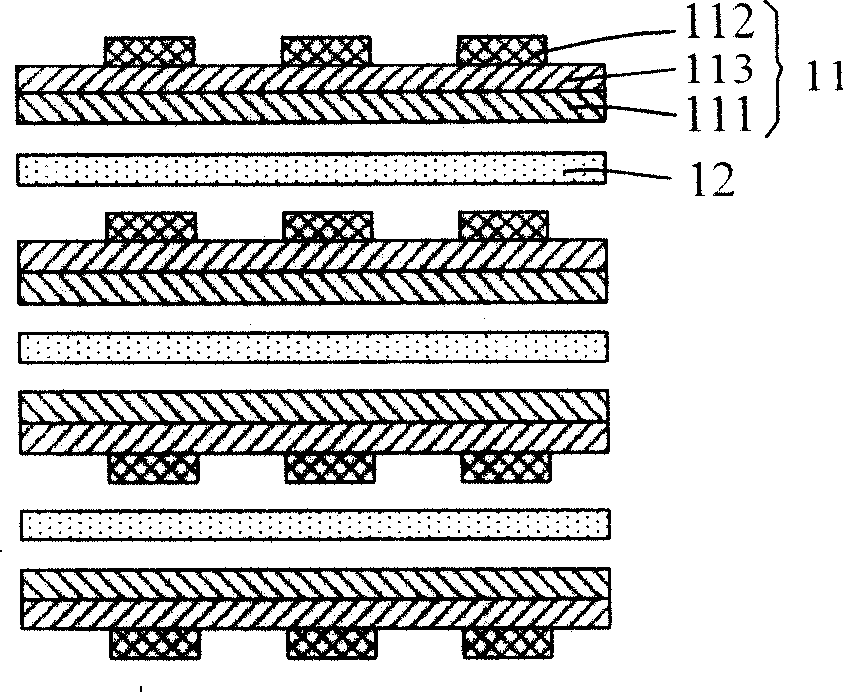

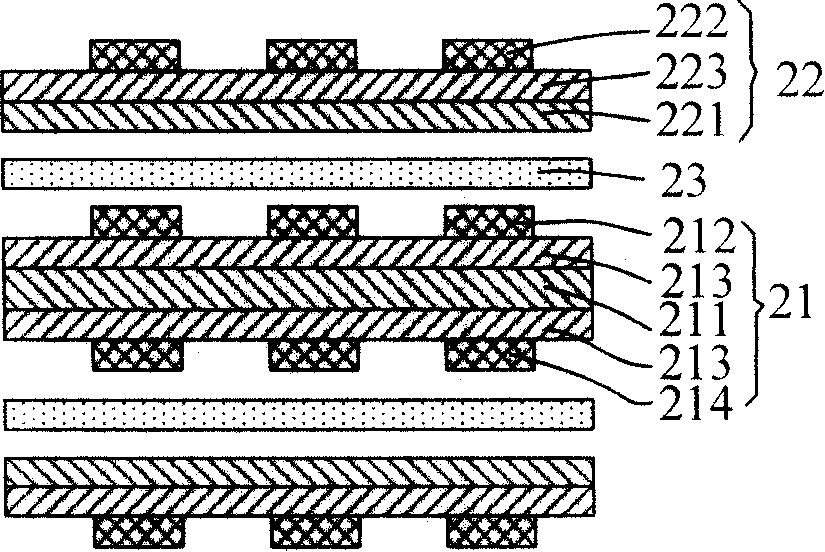

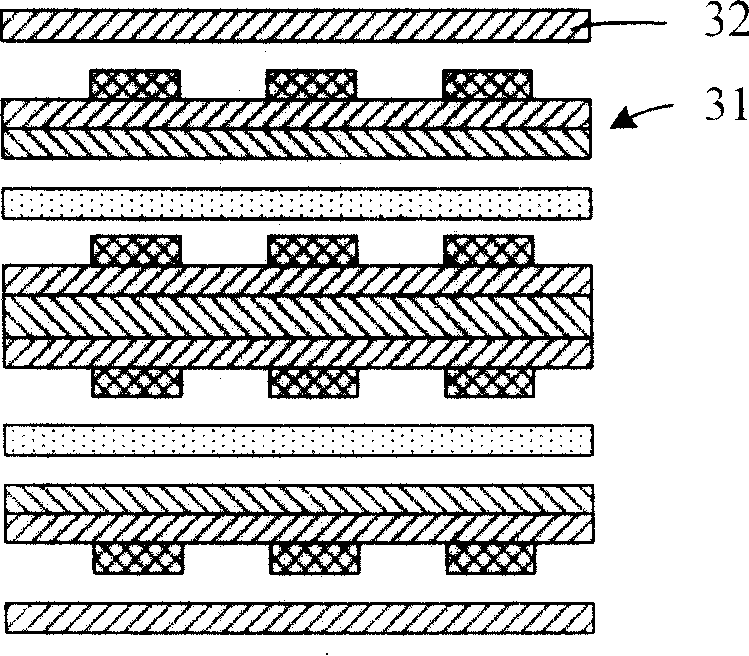

[0015] See 1. The preparation method of the multilayer flexible circuit board of the first embodiment comprises the following steps:

[0016] Step 1, providing four-layer copper-clad laminate 11 and three-layer adhesive layer 12 . The copper clad laminate 11 includes an insulating layer 111 , an intermediate layer 113 and a conductive circuit 112 preformed on the intermediate layer 113 .

[0017] The most commonly used material for the insulating layer 111 and the adhesive layer 12 is polyimide (Polyimide, PI), but it can also be selected from the following polymers such as Teflon (Teflon), polythioamine (Polyamide), polymethacrylic acid Polymethylmethacrylate, Polycarbonate, Polyethylene Terephthalate (PET) or Polyamide polyethylene-terephthalate copolymer or its composition.

[0018] The middle layer 113 can be an adhesive layer, or a chrome middle layer that is plated before the copper foil is plated when the copper-clad laminate 11 is prepared by electroplating. Of cou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com