Installing method of airplane component based on laser positioning

An aircraft component, laser positioning technology, applied in aircraft assembly, active optical measurement device, measurement device and other directions, can solve the problems of the installation position of the catheter bracket cannot be cured, the installation accuracy is low, and achieve accurate and rapid spatial positioning, shortened installation cycle, Resolve difficult-to-cure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

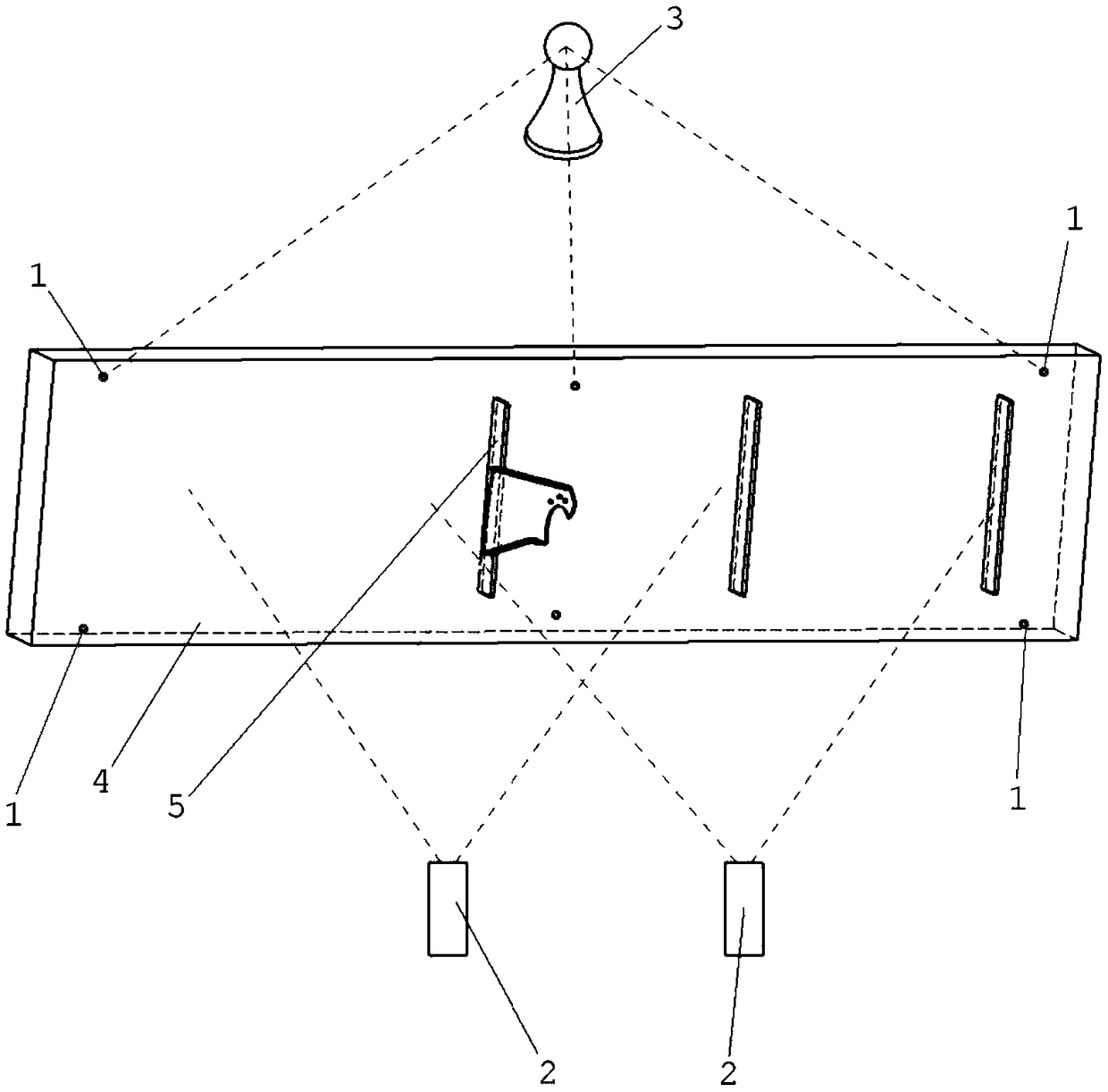

[0020] A method for installing aircraft components based on laser positioning is provided, comprising the following steps:

[0021] Step 1) Determine the area of the laser projection area, find the component installation position coordinates in the aircraft model, take the component installation position coordinates as the center, and take the laser projection area area as the range, select a plurality of reference coordinate points in the aircraft model, and obtain the described Coordinates of multiple reference coordinate points, obtain the relative positional relationship between all reference coordinate points, obtain the relative positional relationship between at least one reference coordinate point and the component installation position coordinates, and obtain the relationship between all reference coordinate points and the fuselage reference plane relative positional relationship;

[0022] Step 2) mark all reference coordinate points on the aircraft fuselage accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com