Method for assembling and locating web-type wing ribs on basis of laser measurement

A technology of laser measurement and positioning method, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems of low accuracy, poor efficiency and high cost, and achieve the effect of improving assembly accuracy and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

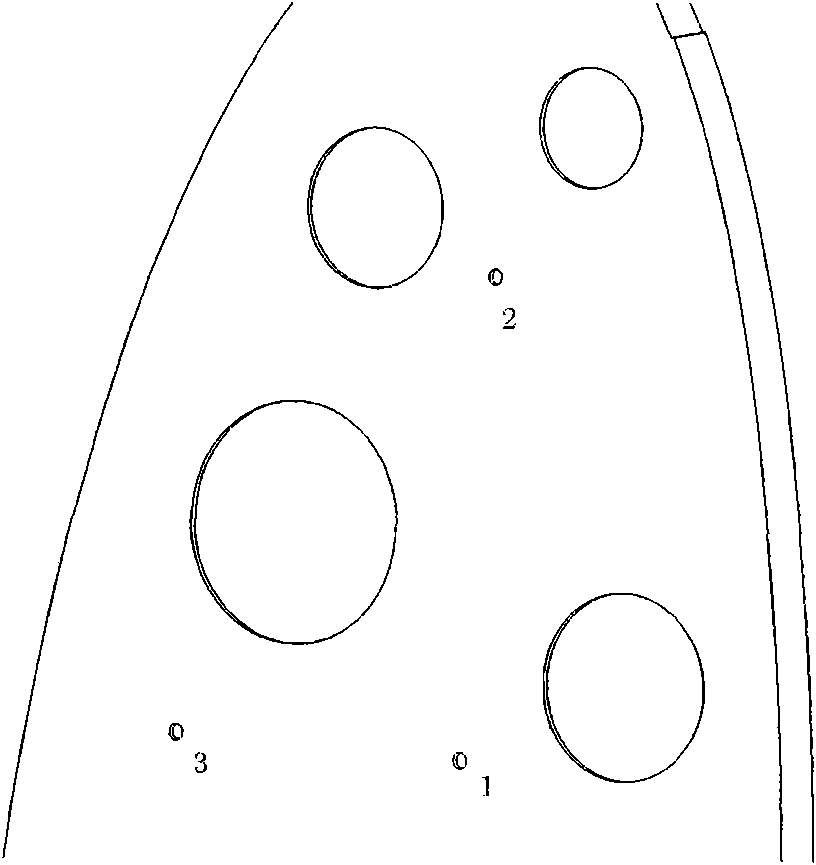

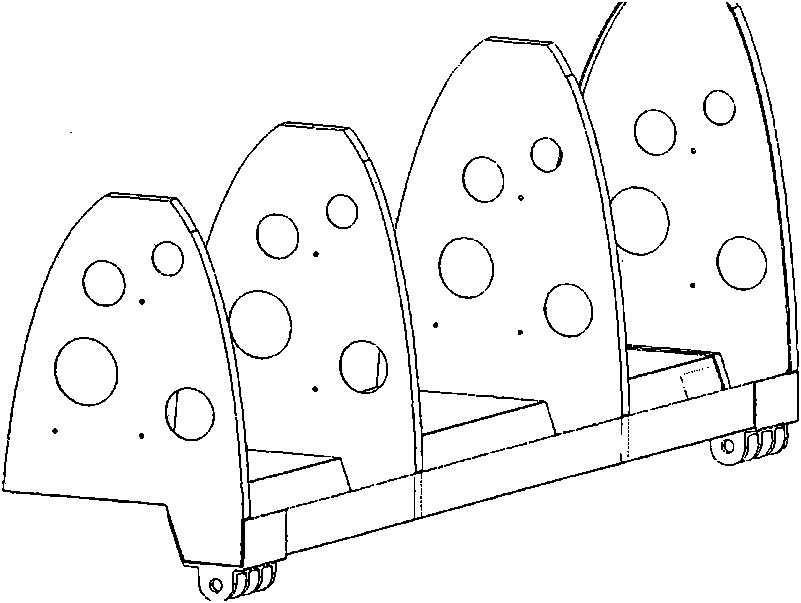

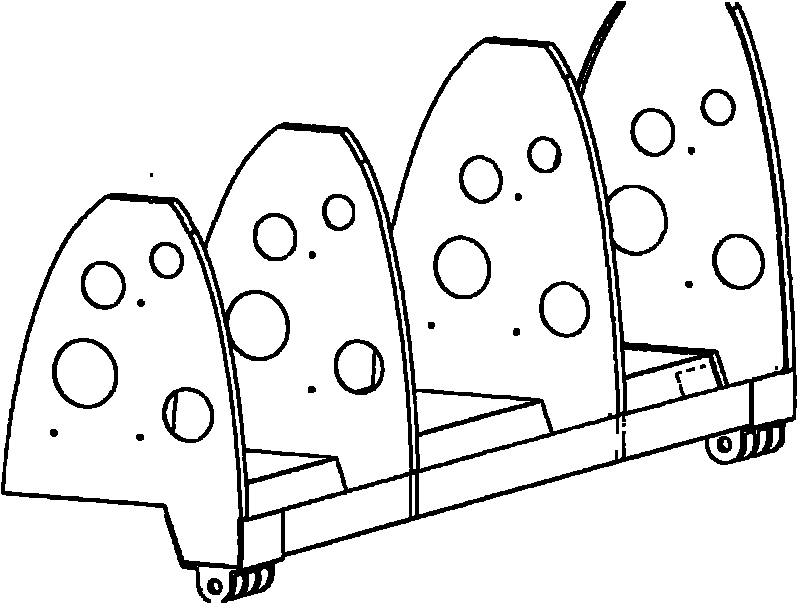

[0034] See figure 1 , the wing web type rib is straight at the top and has a The two sides are double-arc-shaped metal plates, and there are four large holes and three small holes on it. The three small holes are positioning reference holes. They are distributed in a right triangle, and the diameter of the holes is selected To ensure the strength requirements of the wing rib. The rib is attached to the wing's stringers and skin, which are assembled after the rib is assembled.

[0035] The concretely implemented group of web-type ribs has 4 rib parts, respectively numbered rib 1#, rib 2#, rib 3# and rib 4#, and the theory of 3 positioning reference holes for each rib The design data are shown in Table 1. After checking the strength of each rib and the overall strength, the diameter of the positioning reference hole of this group of rib parts is selected as 6mm.

[0036] Table 1 Theoretical design data of 1# rib assembly positioning datum hole

[0037]

[0038] See fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com