Longitudinal tensile loading trajectory design method based on mold surface extension

A technology of mold profile and loading trajectory, applied in simulators, computer control, instruments, etc., can solve the constraints on the overall level of aircraft manufacturing, the lack of loading trajectory definition CNC drawing machine programming software, and the difficulty in meeting the production of new aircraft skin parts Requirements and other issues to achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

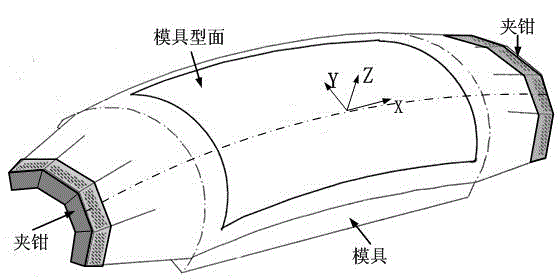

[0034] Example: see Figure 1 to Figure 5 .

[0035] Based on ACB FEL series CNC longitudinal drawing machine, a design method of longitudinal drawing loading trajectory based on mold surface extension, the specific implementation steps of this method are as follows:

[0036] Step 1: Mold surface extension

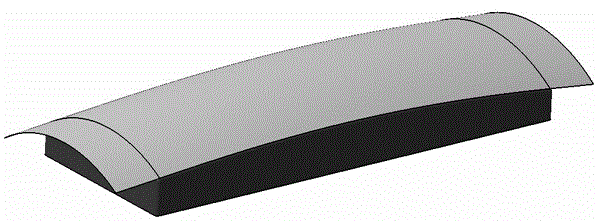

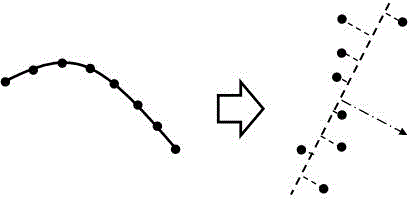

[0037] The extension of the mold surface is to extend the mold surface to both sides along the stretching direction for a certain length l. The extension process can be done in commercial CAD software. The specific method of extension is as follows, see figure 2 :

[0038] Firstly, extract the surface of the skin pulling mold, or directly copy the surface of the mold design. Due to the thickness of the wool, the mold surface cannot be directly used for extension. The mold surface should be offset to the outside of the mold. The offset distance is:

[0039]

[0040] Where T is the wool thickness.

[0041]Then, the mold surface is extended to both sides along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com