Modeling method for two-dimensional variable-curvature process model of section bar part

A technology of process model and modeling method, which is applied in special data processing applications, instruments, electrical digital data processing, etc., and can solve the problem that the forming accuracy of parts cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

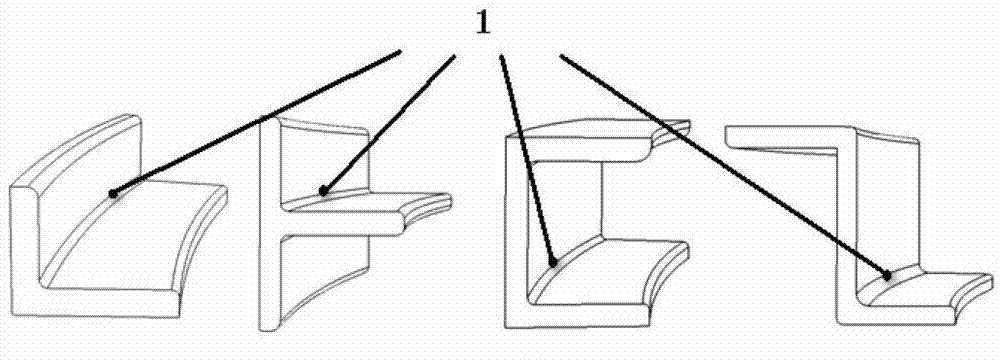

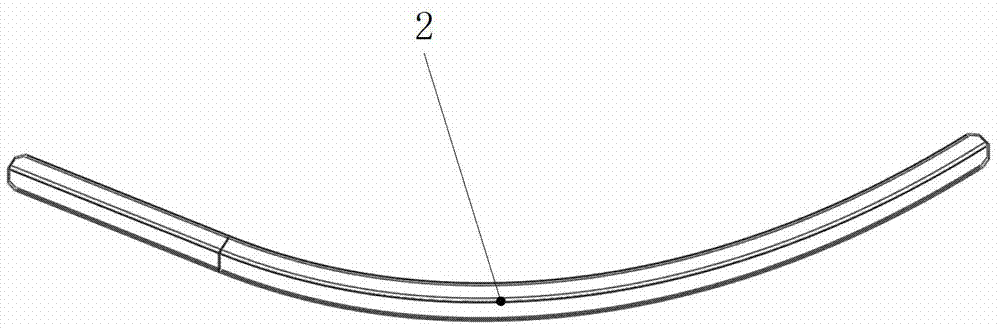

[0049] by figure 2 Take the part shown as an example, which is a variable curvature, asymmetrical L-shaped section profile part, and design the process model of the part. Combined with the accompanying drawings, the specific implementation process of process model definition is described.

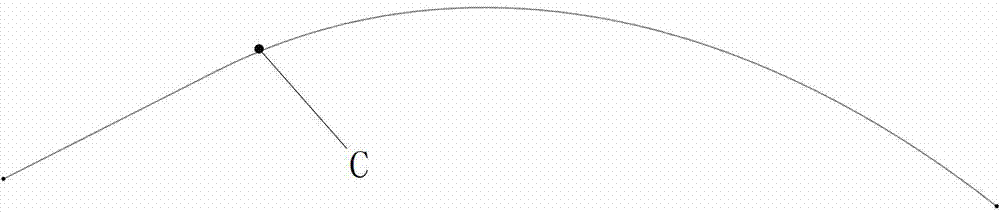

[0050] 1. Extract the inner contour line C of the part, the length of the contour line l=665, and the two endpoints of the contour line C are respectively P Start and P End , the highest point P of the contour line Top is the contour line C up to the straight line The point with the greatest distance, P Top Divide the contour line C into two segments C 1 , C 2 , with length l 1 =330, l 2 =335 as image 3 , 4 shown.

[0051] 2. Take Δl=5mm, for l 1 and l 2 Discrete, the discrete points are P 11 ,...,P 1(67) and P 2i ,...,P 2(68) Such as Figure 5 shown....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com