Laminated plate aircraft skin with flow control and deicing prevention functions

A technology of flow control and aircraft skin, applied in deicing devices, aircraft parts, layered products, etc., can solve the problems of single function of laminated aircraft skin, difficulty in stably installing plasma actuators, etc., and delay stall , Increase the maximum lift coefficient, reduce the effect of differential pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The manufacture and application of the present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not used as a basis for any limitation of the present invention.

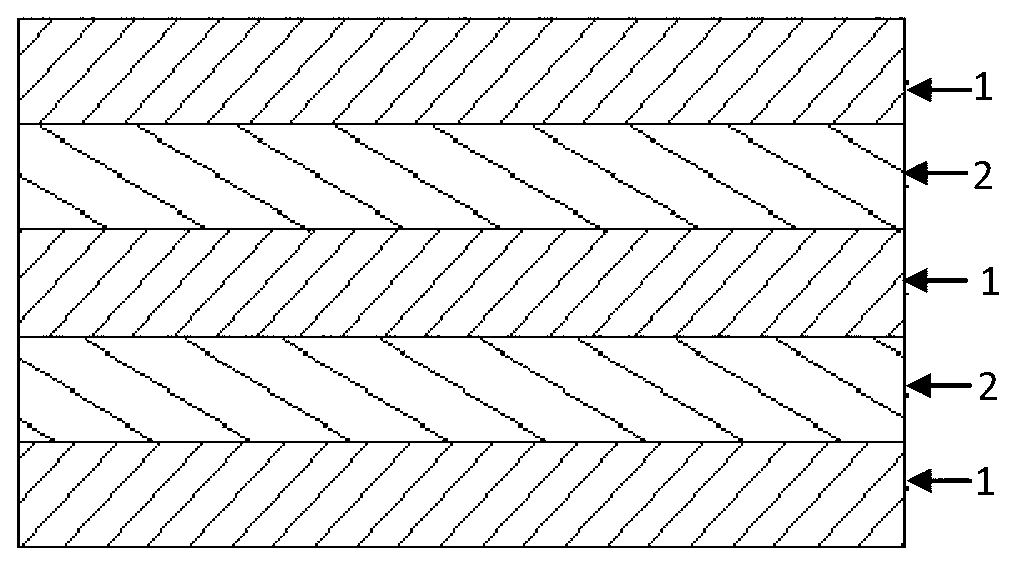

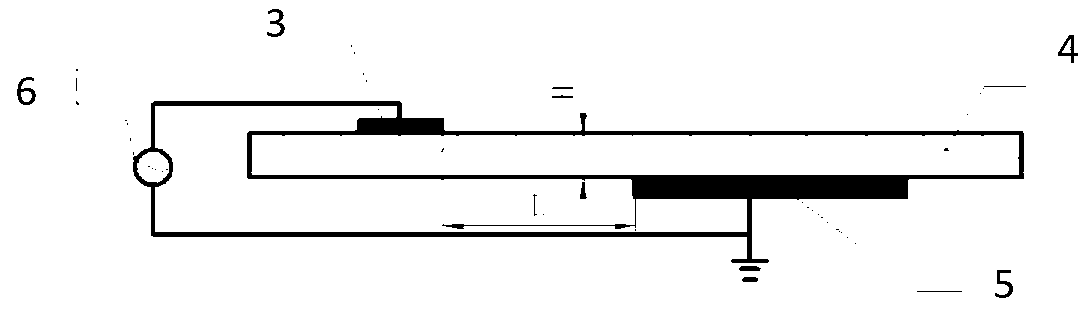

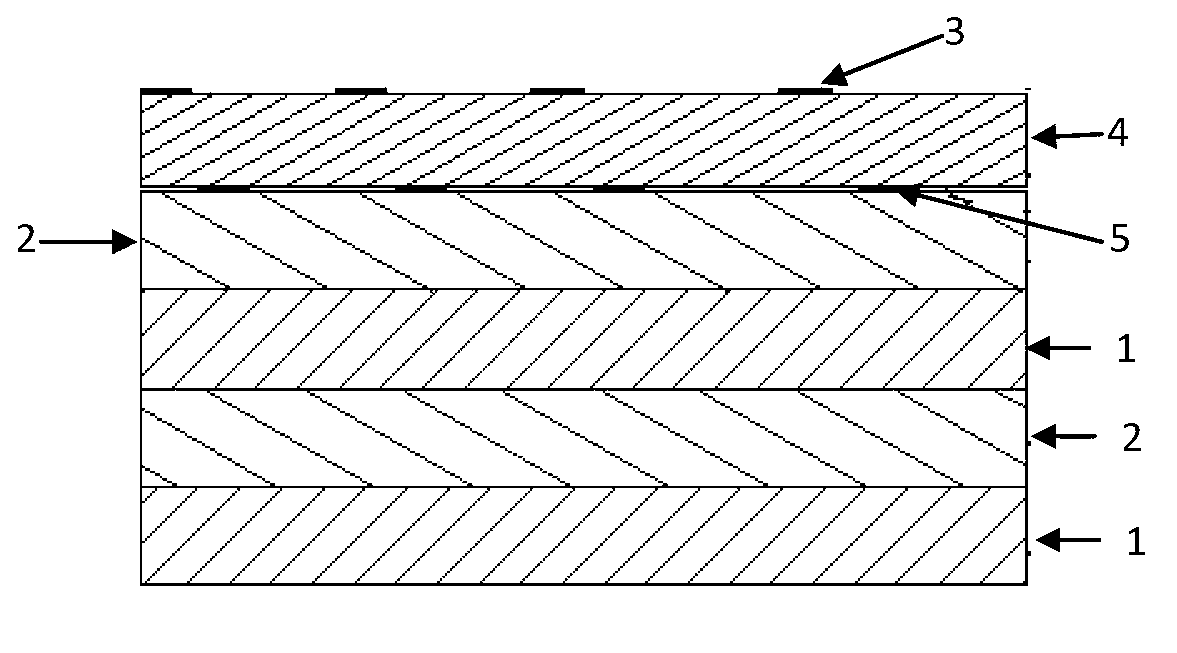

[0019] A laminated aircraft skin with flow control and anti-icing functions, comprising glass fiber layers (2) and aluminum alloy layers (1), the glass fiber layers (2) and aluminum alloy layers (1) alternate with each other; the skin The surface is provided with an insulating material layer (4) and an electrode layer. The electrodes are divided into upper and lower layers. The two layers are respectively located on both sides of the insulating material layer (4) and are distributed asymmetrically. The upper electrode layer (3) is exposed to the air. , connected to an AC power supply, the lower electrode layer (5) is located under the insulating material layer (4) and grounded.

[0020] The electrode layer (3, 5) is made of copper sheet or aluminum al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com