Skin roll-bending part sectional curvature analysis method

A part and roll bending technology, which is applied in the field of section curvature analysis of skin roll bending parts, can solve problems such as insufficient efficiency and time-consuming process personnel, and achieve the effects of improving efficiency, reducing workload, and reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Example: see Figure 1 to Figure 9 .

[0023] A method for analyzing the curvature of a section of a skin roll bending part, the specific implementation steps of the method are as follows:

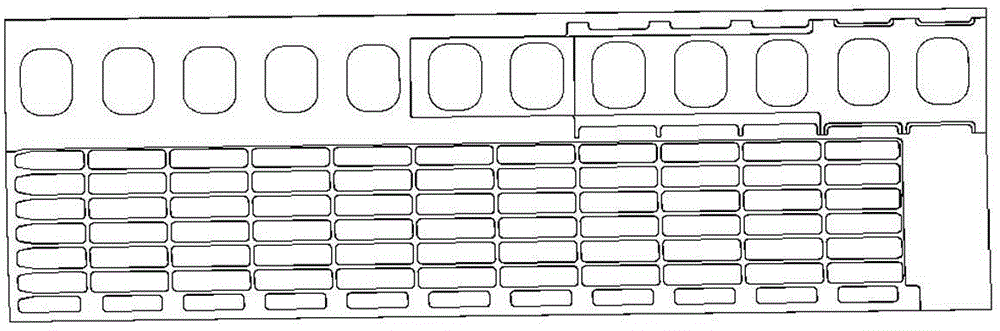

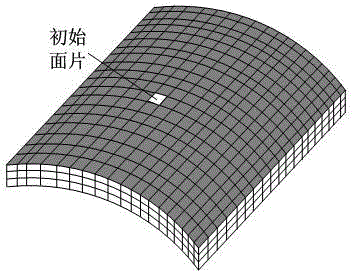

[0024] Step 1: Dial-to-analog discretization of parts

[0025] The digital-analog discretization of parts is to discretize the mesh of the skin rolling parts, and discretize the geometric model into a grid model, which is realized in commercial CAD software (CATIA) or commercial finite element preprocessing software (HyperMesh). The method in the present invention can operate on various mesh models, including pure triangular mesh, pure quadrilateral mesh and mixed element mesh in the shell element mesh model, and pure six-node five-point mesh in the volume element mesh model. Hedra meshes, pure eight-node hexahedral meshes, and mixed-element meshes.

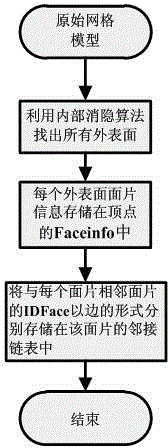

[0026] Step 2: Discrete Mesh Surface Segmentation

[0027] The discrete mesh surface segmentation is based on the surface topolog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com