Aluminum alloy skin digital assembly method

An assembly method and technology of aluminum alloy, applied in aircraft assembly, ground installation, transportation and packaging, etc., can solve the problems of dislocation of skin shape and skeleton shape, low assembly accuracy, low repeat accuracy, etc., to improve assembly efficiency and assembly. quality, achieving production interchange and use interchangeability, the effect of reliable positioning systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A kind of aluminum alloy skin digital assembly method of the present invention, its specific process is as follows:

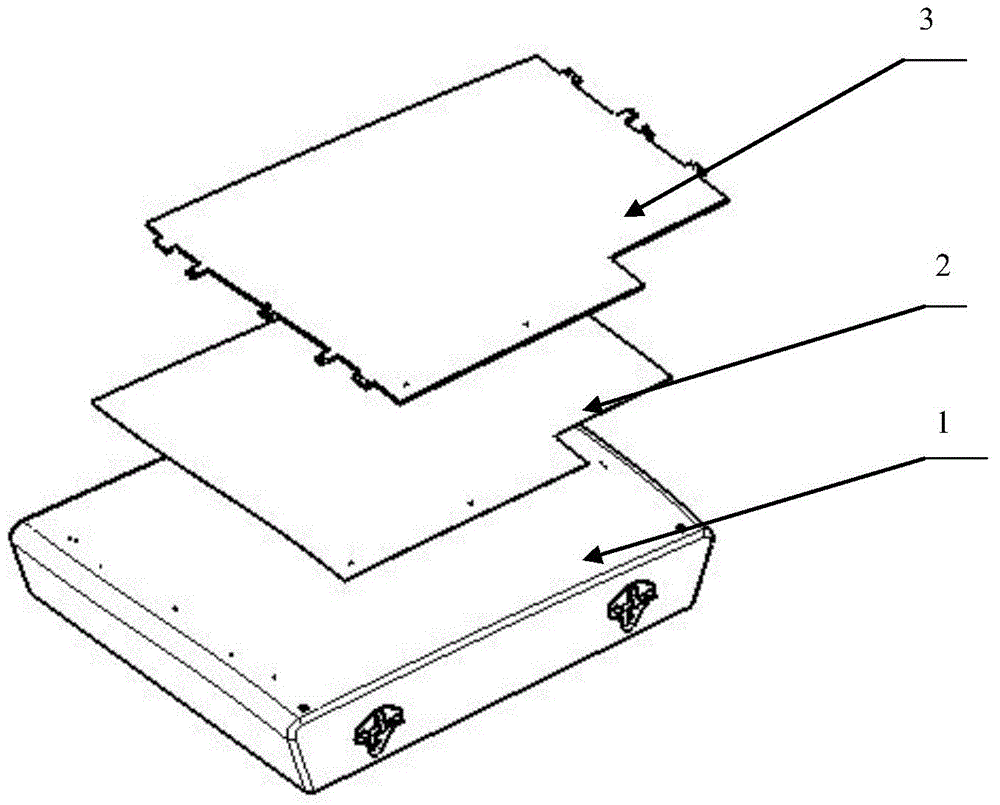

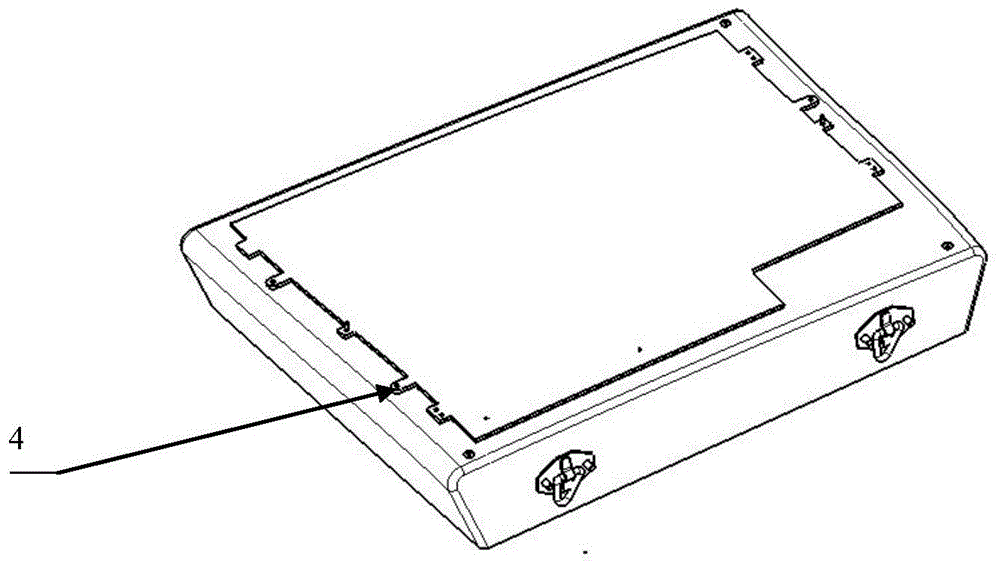

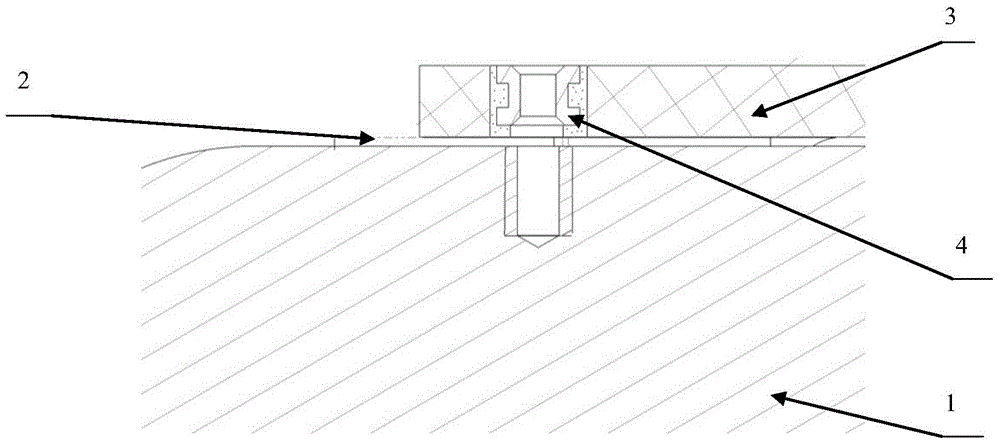

[0023] Step 1: Drill holes for positioning the craft lugs on the stretch tire

[0024] Using digital technology to manufacture stretching tires and riveting assembly fixtures, on the stretching tires, use a glass fiber reinforced plastic plate to drill molds in the skin margin area to drill the positioning holes for the process lugs, and the positioning holes for the process lugs are selected in the skin stretching The symmetrical area with small deformation and small curvature change provides accurate processing and assembly positioning references for the subsequent processing of the skin; in addition, because the stretch tire and the pressure plate drilling jig use digital manufacturing methods, the positioning of the process lugs is guaranteed. The holes are highly coordinated with the skin geometry, such as figure 1 , 2 , 3, 4 shown;

[0025] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com