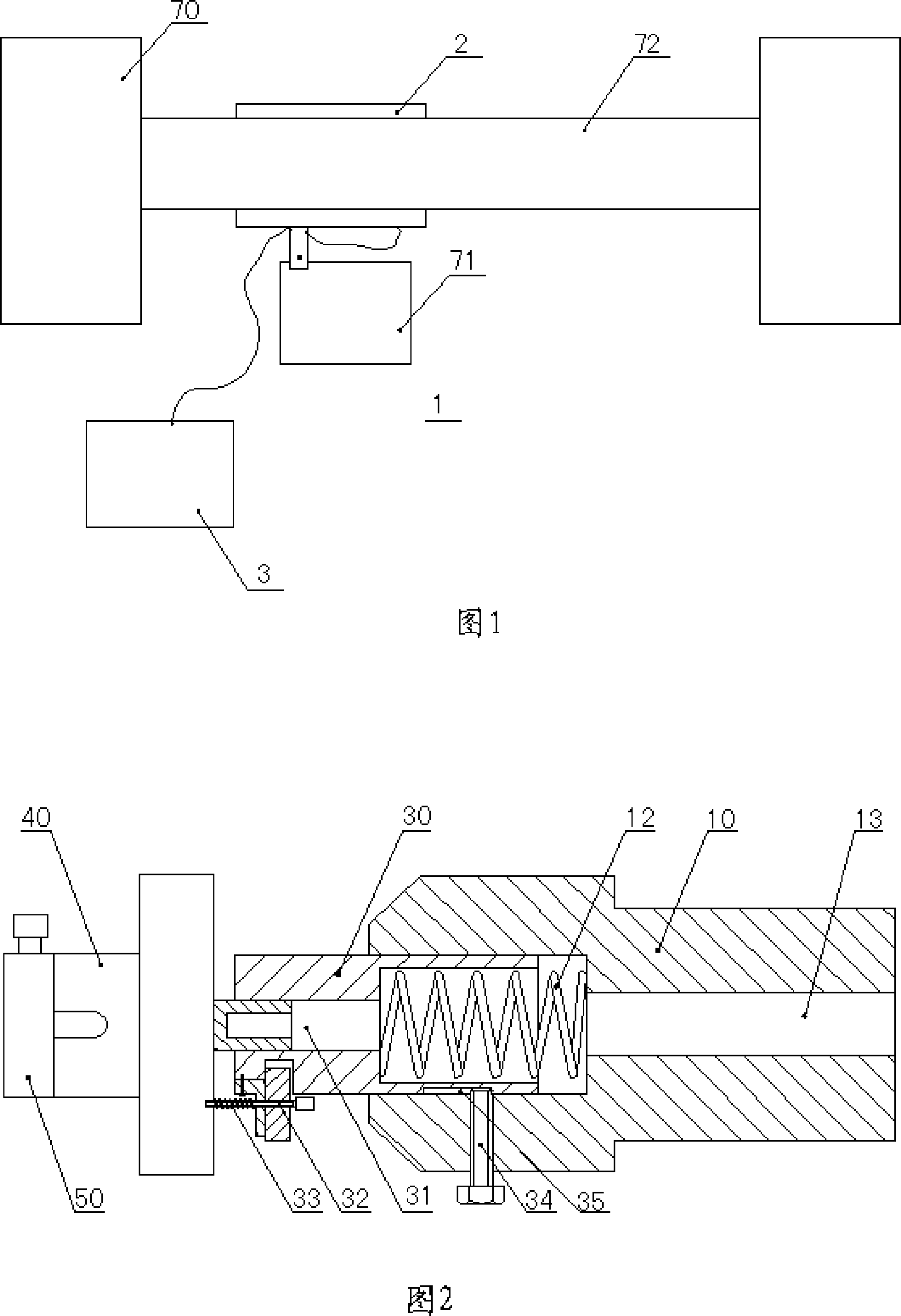

Supersonic wave on-line flaw detection method and its device

A flaw detection device and ultrasonic technology, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problems of heavy manual flaw detection workload, high labor intensity and high detection cost, so as to improve the speed and efficiency of flaw detection and ensure manufacturing quality. , the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

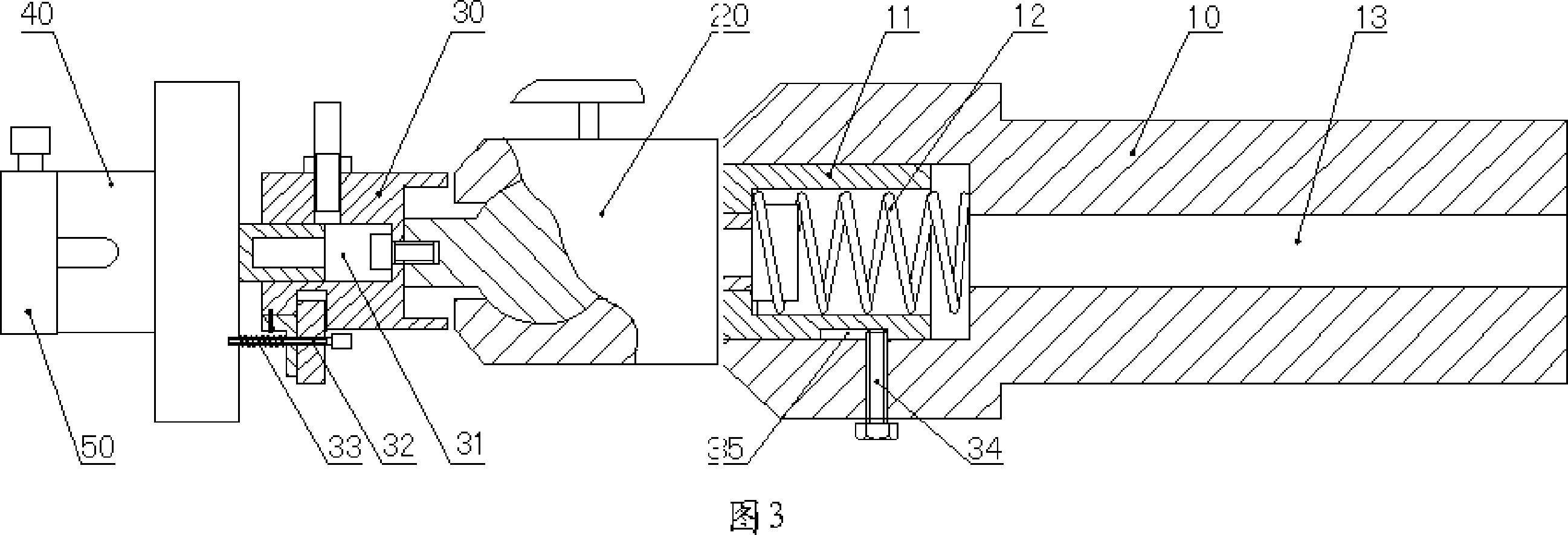

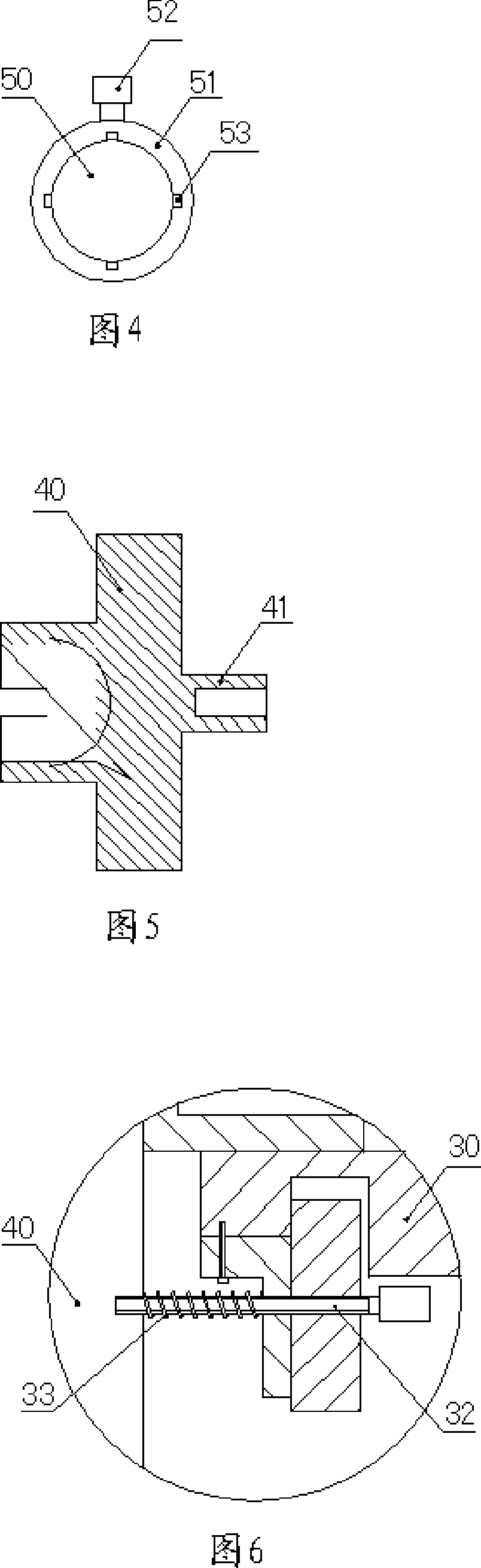

[0036] As shown in the probe device 1 shown in Figure 2, the probe base 40 is connected to the pole 10 through the connecting sleeve 30, and the anti-collision mechanism includes an axial hole opened at the front of the pole 10 and a The shock absorber 12, the connecting sleeve 30 is slidably matched with the axial guide hole, and the shock absorbing spring 12 acts axially on the connecting sleeve 30. Referring to Fig. 2 and Fig. 3, there is also a limiting structure between the connecting sleeve 30 and the pole 10 to limit the sliding distance of the connecting sleeve 30 in the axial guide hole, the limiting structure includes a limiting slot 35 and a screw 34 to limit A slot 35 is provided on the outer wall of the connecting sleeve 30 and extends axially. The screw 34 is installed on the pole 10 , and its head passes through the side wall of the axial guide hole and extends into the limiting slot 35 .

Embodiment 2

[0038] Probe device 1 as shown in Figure 3, for the probe device 1 can be installed on the lathe tool rest easily and can adjust the position of ultrasonic probe 50 flexibly, between described pole 10 and probe seat 40, be provided with multiple The degree of freedom adjustment mechanism 20 and the probe base 40 are connected to the multi-degree-of-freedom adjustment mechanism 20 through the connecting sleeve 30 . The anti-collision mechanism includes an axial guide hole opened at the front of the strut 10 and a shock absorbing spring 12 inside, as well as a sleeve 11 connected to the multi-degree-of-freedom adjustment mechanism 20, the sleeve 11 and the axial guide hole Sliding fit, the damping spring 12 acts axially on the sleeve 11 . In consideration of simplifying the structure of the probe device 1 as much as possible, the multi-degree-of-freedom adjustment mechanism 20 may preferably adopt the spherical universal joint shown in FIG. 3 .

[0039]In Embodiment 1 and Embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com