Energy-saving hydraulic sealing experimental bench and method thereof

A technology of hydraulic sealing and test bench, which is used in liquid/vacuum measurement for liquid tightness, by measuring the acceleration and deceleration rate of fluid, measuring device and other directions, which can solve the problem of high energy loss, limited performance data of sealing components, and inability to understand The anti-leakage performance of sealing components can achieve the best energy saving effect and the effect of adjustable pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

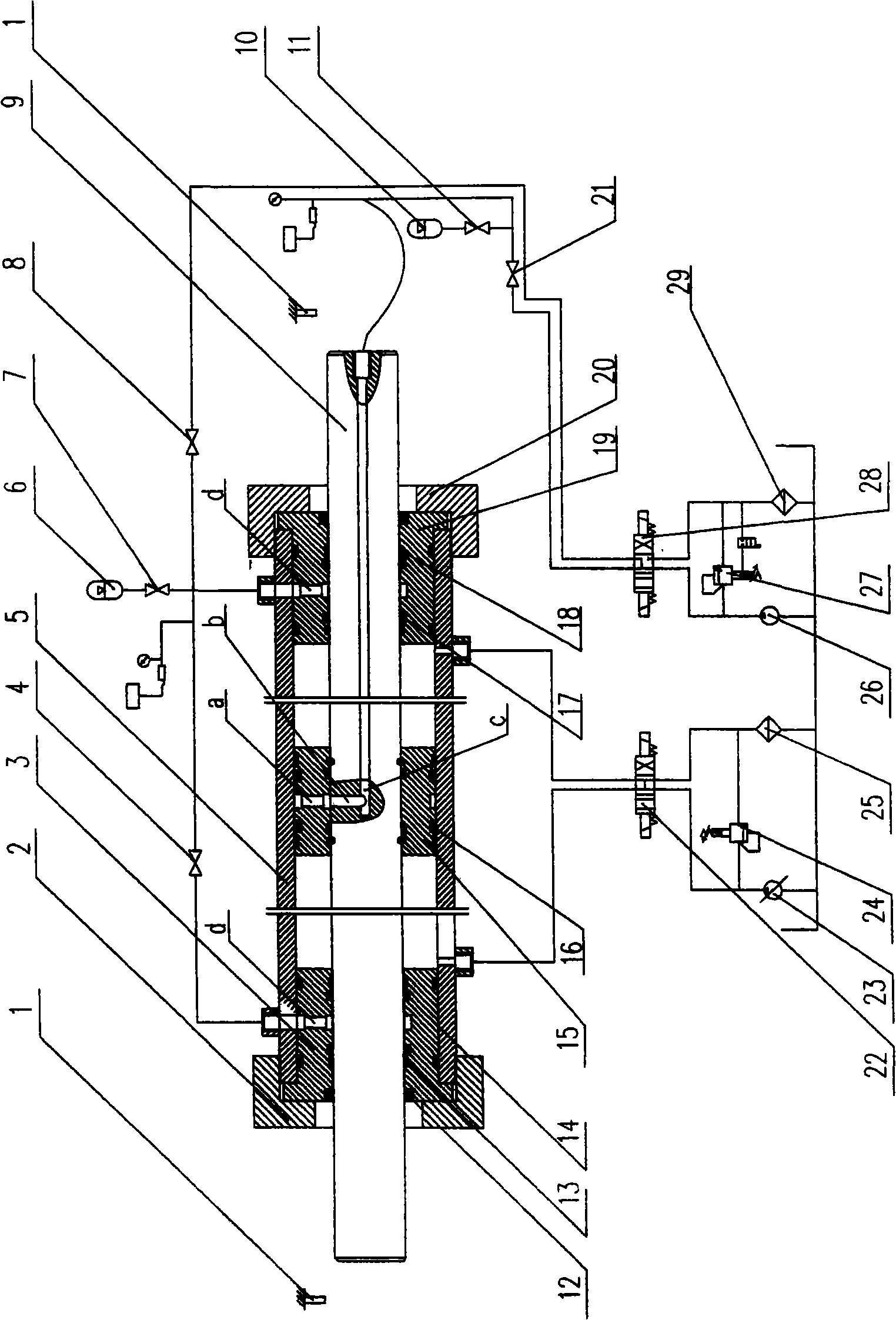

[0018] With reference to accompanying drawing, the present invention is made up of three parts of experiment oil cylinder, experiment oil cylinder driving circuit and loading circuit; Rod (9), right guide sleeve (19), right cylinder cover (20) form. The cylinder (5) is made of seamless steel pipe, and the outer circular surfaces at both ends are threaded structures; 4 radial through holes are processed in the radial direction, and an oil pipe is welded on the outer cylindrical surface of each radial through hole Joint; Piston (15), left guide sleeve (3) and right guide sleeve (19) are housed in the cylinder barrel (5).

[0019] The left end cap (2) and the right end cap (20) are both cylindrical structures, and are processed with a through hole with a smaller aperture and a threaded hole with a relatively larger aperture along the central axis, and the left and right end caps are connected to the cylinder barrel through threads.

[0020] Piston (15) and piston rod (9) are fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com