Laser coaxial powder feeding composite manufacturing machine tool and workpiece composite manufacturing method

A technology of coaxial powder feeding and machine tools, which is applied in the field of machine tools, can solve problems such as difficult to control precision and quality defects of parts, and achieve the goal of ensuring manufacturing quality and precision, precision additive and subtractive integrated composite manufacturing, and high dimensional accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

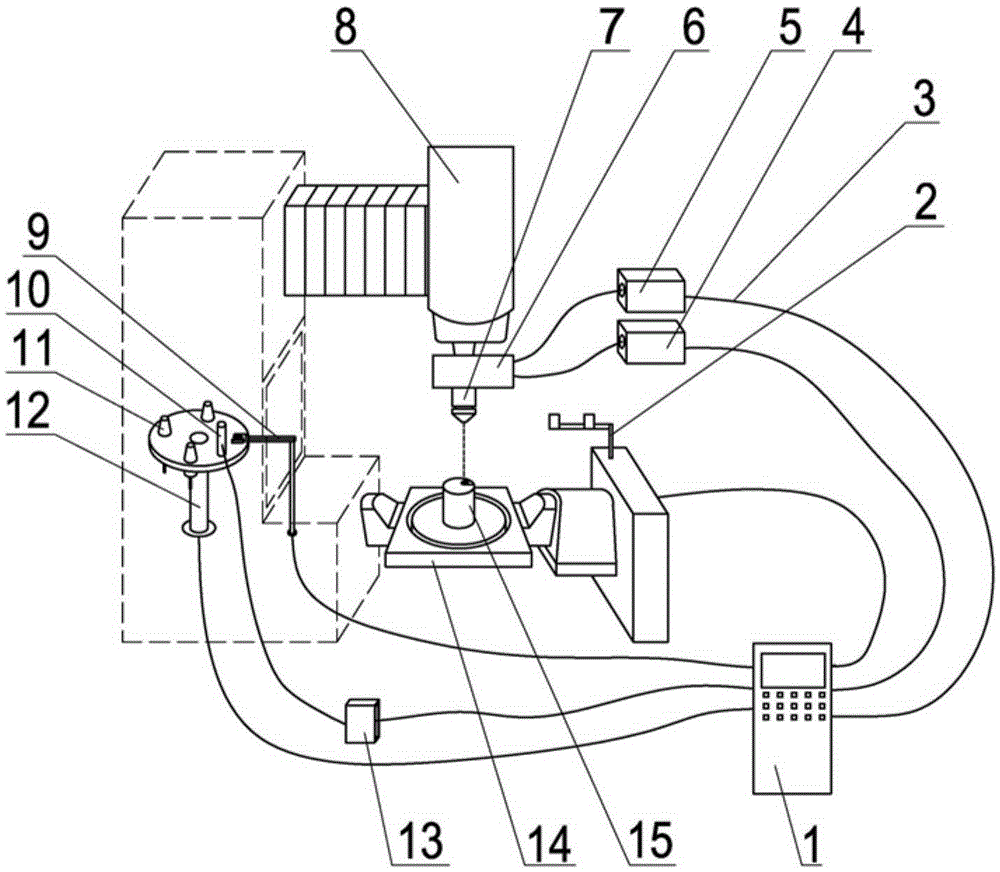

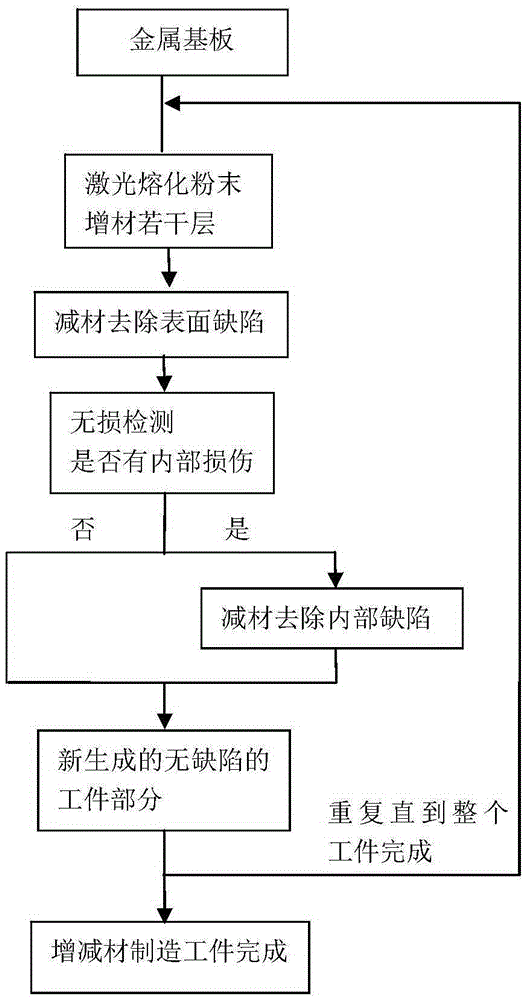

[0020] Such as figure 1 As shown, a compound manufacturing machine tool includes a cradle-type workbench 14, a spindle 8, an additive manufacturing mechanism, a material-subtractive processing mechanism and a defect detection mechanism capable of on-line detection of workpiece defects. The machine tool is equipped with a cradle-type working Table 14, the workbench 14 can rotate around the horizontal axis and the vertical axis, the main shaft 8 is arranged above the workbench 14, the additive manufacturing mechanism includes a nozzle 7 and a powder feeding device 4 connected to the nozzle 7, The nozzle 7 is provided with a laser head 6. In this embodiment, the nozzle 7 is a coaxial powder feeding nozzle. The laser head 6 is connected to the laser generator 5 through an optical fiber 3. The additive manufacturing mechanism is composed of a nozzle bracket 2 Clamping, the nozzle bracket 2 can install the nozzle 7 on the spindle 8 or unload the nozzle from the spindle 8, the subtra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com