Laminated structure hole manufacturing online monitoring self-adaptive machining method

A technology of laminated structure and processing method, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve problems such as difficulty in ensuring the quality of hole making and the impact of tool wear, and achieve the goal of improving quality and hole processing efficiency and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

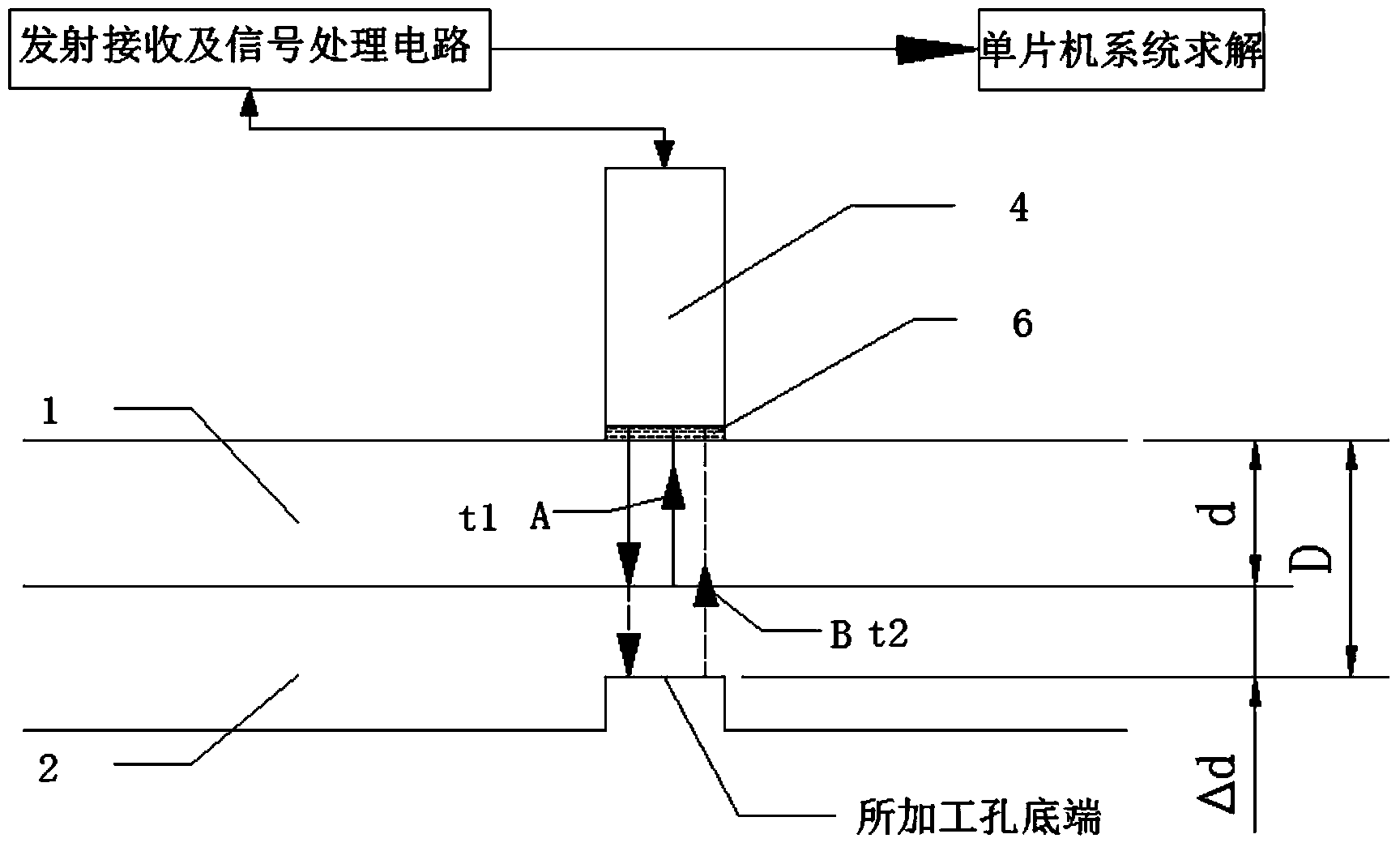

[0017] As a preferred embodiment of the present invention, the ultrasonic thickness measurement method specifically includes the following steps:

[0018] (a) Fix the ultrasonic probe 4 in close contact on the bottom surface of the laminated structure of the carbon fiber reinforced composite material and the alloy material coated with the couplant 6, so as to ensure that the ultrasonic probe is always relative to the made hole; the couplant is available on the market , light engine oil can be used.

[0019] (b) Excite the ultrasonic probe to emit ultrasonic waves, the ultrasonic probe receives the reflected ultrasonic signal B at the hole-forming position of the laminated structure that the bottom end of the cutter arrives at and the reflected ultrasonic signal A at the material interface in the laminated structure, and then the received ultrasonic signal The signal is output to the transmitting, receiving and signal processing system and then output to the single-chip microco...

Embodiment 1

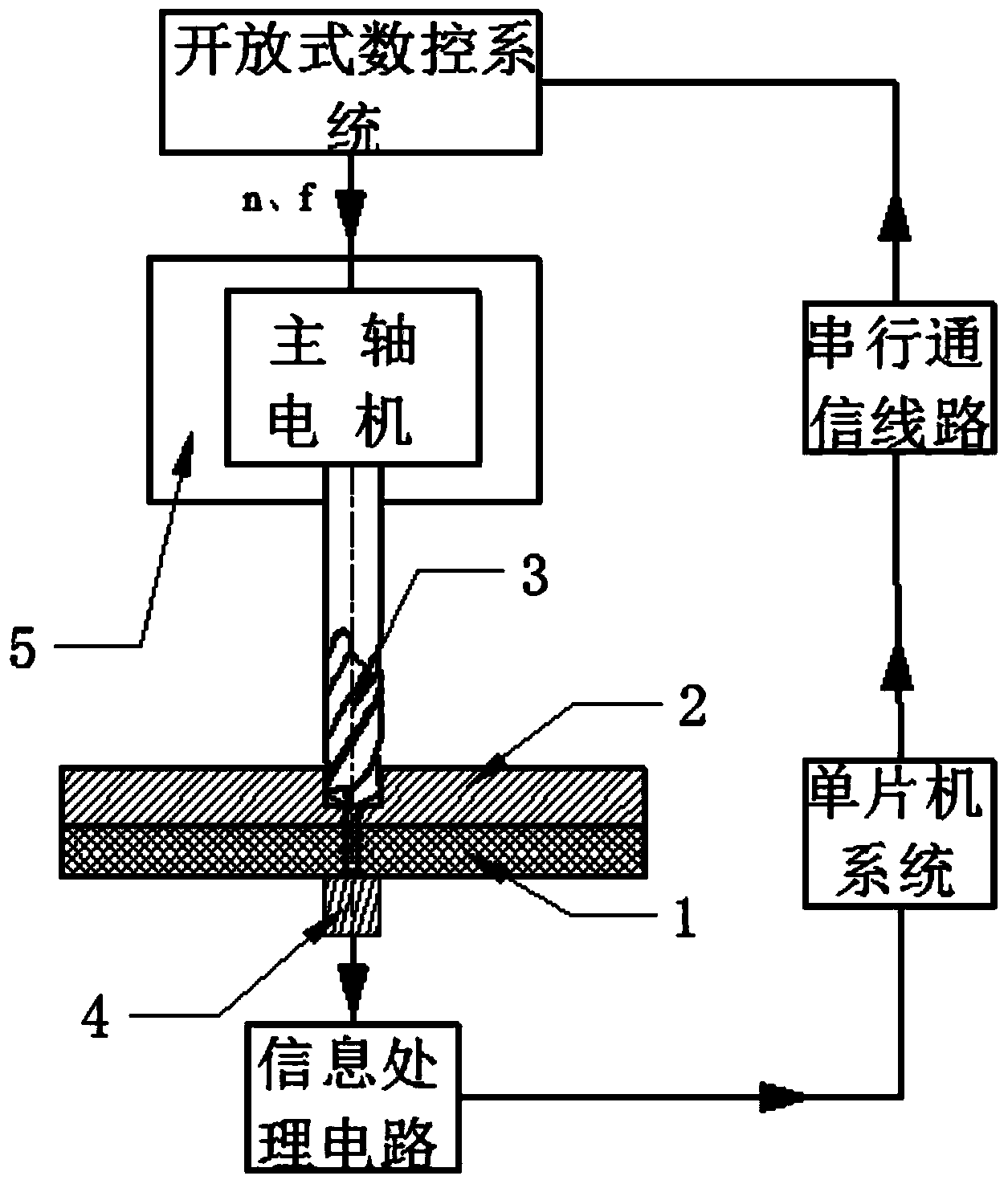

[0024] (1) When the hole-making tool 3 installed on the CNC machine tool is used to make holes in the laminated structure of carbon fiber reinforced composite material 2 and alloy 1, the layered structure formed by the bottom end of the hole-making tool is measured by ultrasonic thickness measurement. The distance value between the position and the material interface in the laminated structure, and then transmit the distance difference signal to the control system of the CNC machine tool where the hole-making tool is installed;

[0025] The ultrasonic thickness measurement method specifically includes the following steps:

[0026] (a) Fix the ultrasonic probe 4 in close contact on the bottom surface of the laminated structure of the carbon fiber reinforced composite material and the alloy material coated with the couplant 6, so as to ensure that the ultrasonic probe is always relative to the made hole; the couplant is available on the market , light engine oil can be used.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com