Method and equipment for manufacturing three-dimensional object

A technology for three-dimensional objects and equipment, which is applied in processing and manufacturing, manufacturing tools, and additive manufacturing. It can solve the problems of large substrate transfer thermal resistance, low heat transfer efficiency, and long heating time, so as to reduce thermal effects and reduce stress. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

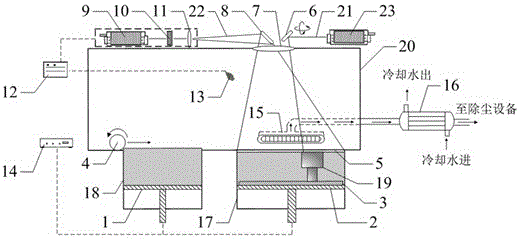

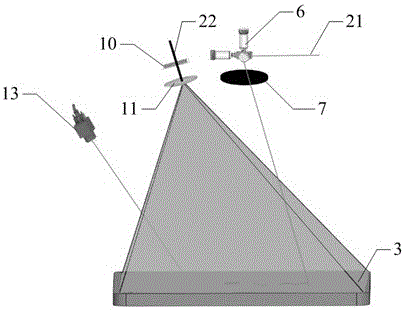

[0037] The following will refer to figure 1 and figure 2 An exemplary apparatus for manufacturing a three-dimensional object and its preheating system according to the present invention are described.

[0038] Such as figure 1 Shown is a specific embodiment of a device capable of implementing the present invention, which is a selective laser melting device. This laser melting equipment has a forming cylinder 17 opening upwards, and a support 2 for supporting a three-dimensional object 19 to be formed is arranged in the forming cylinder 17, and the support 2 can move vertically in the forming cylinder 17 by means of a driving device 14 Move up and down.

[0039] The upper edge of the forming cylinder 17 defines the working plane 5 . A scanning laser 23 is arranged above the working plane 5, which emits a scanning beam 21 and is guided onto the working plane 5 by a scanning deflection mirror 6 for scanning. cross section. There is also a preheating system above the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com