Automated people mover (APM) monorail system

a technology of automatic people mover and monorail system, which is applied in the direction of locomotives, transportation and packaging, roads, etc., can solve the problems of premature suspension failure, high tire wear, and conventional design that is often neither suitable nor economical for all weather operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

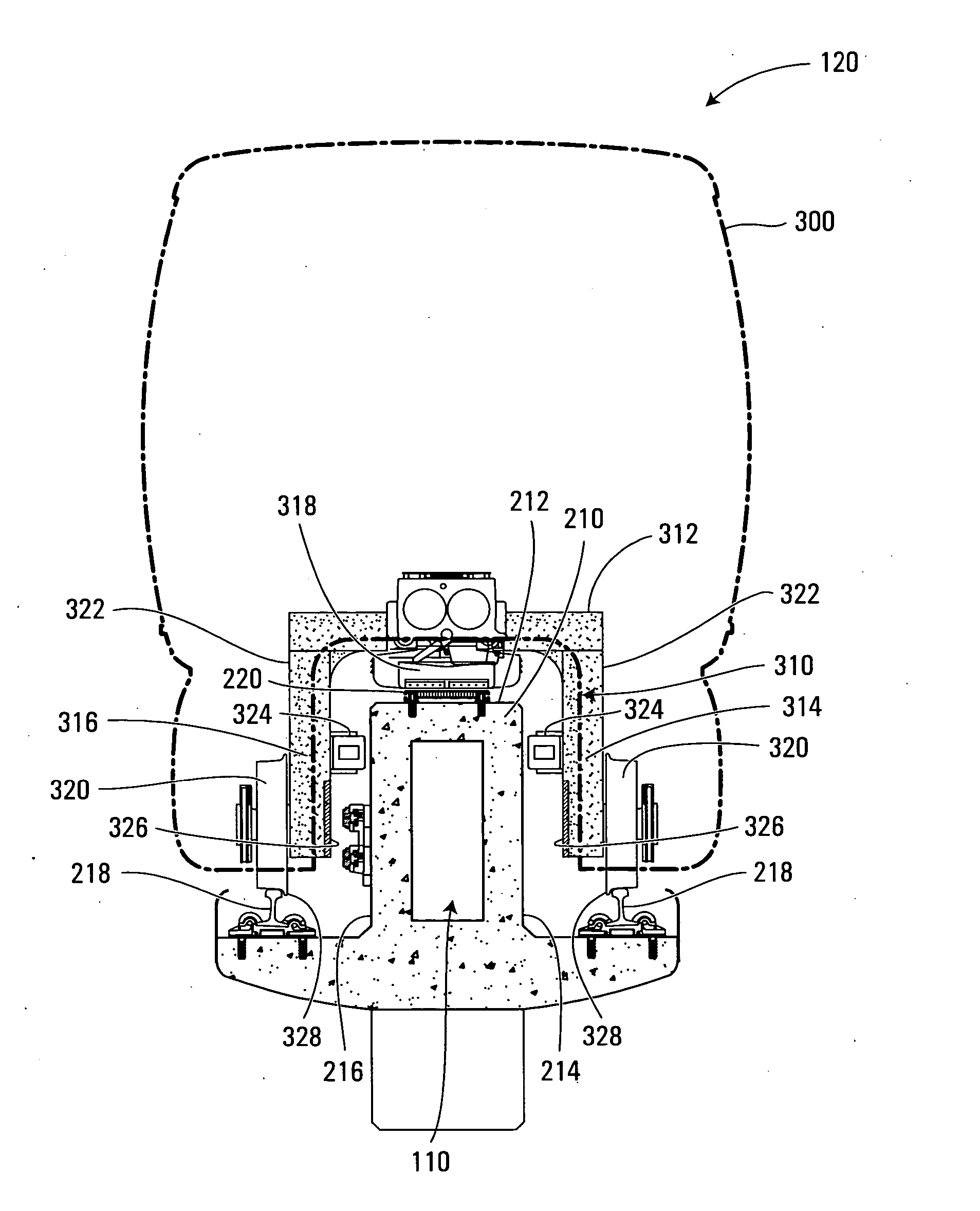

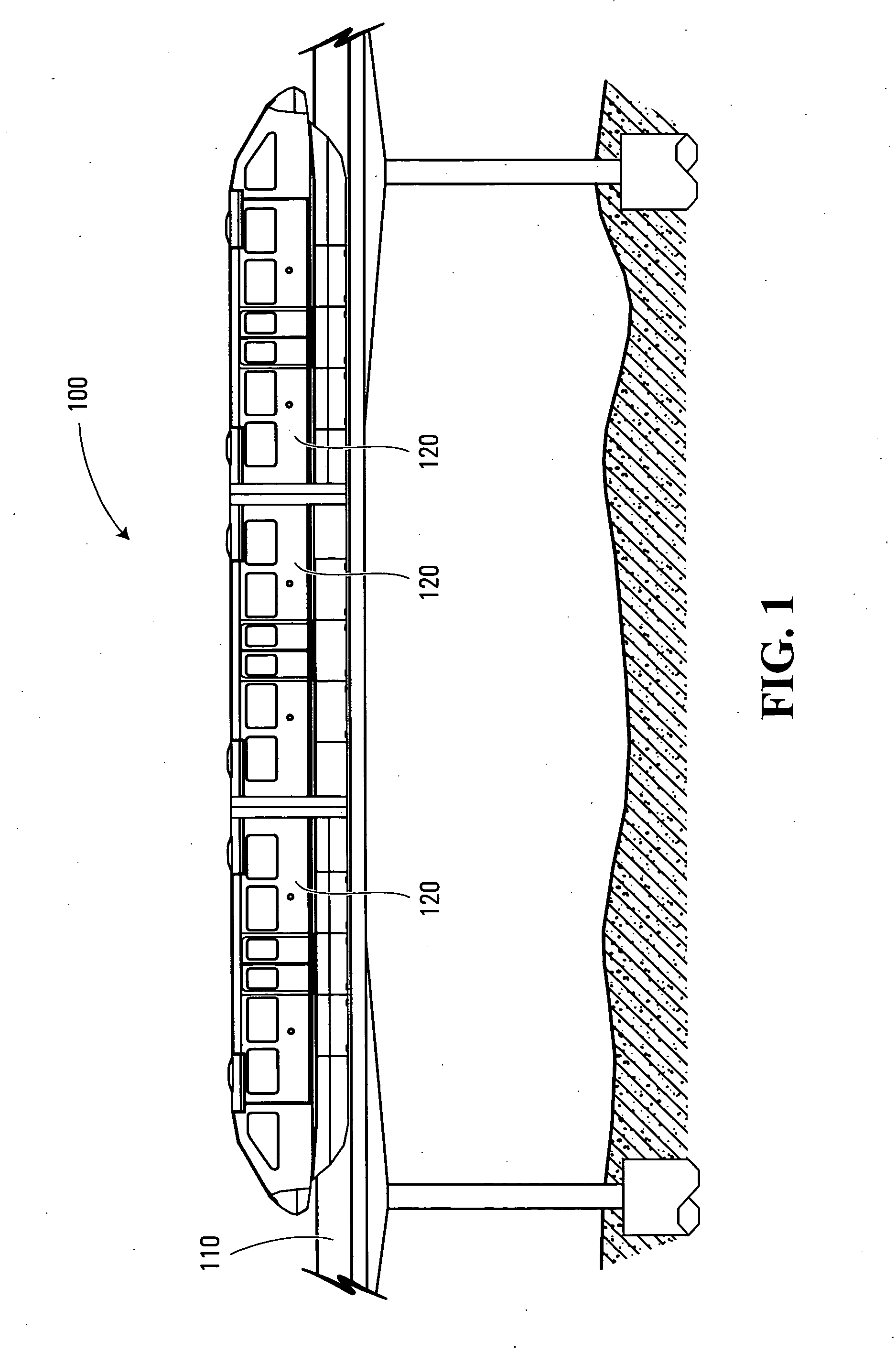

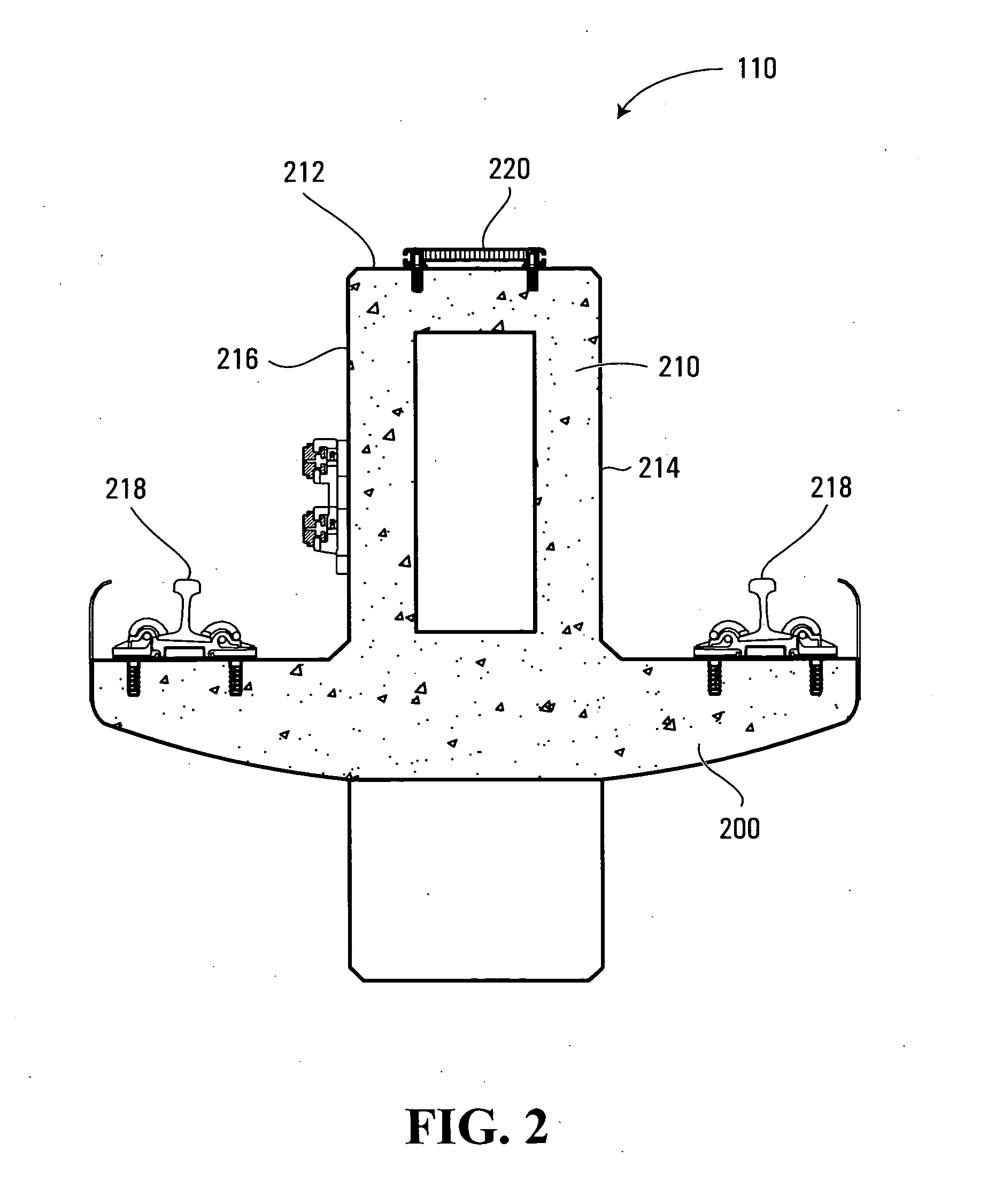

[0018] The Automated People Mover (APM) monorail system shown in FIG. 1 is an integrated system approach to the vehicle / guideway beam arrangement, in accordance with a non-limiting example of implementation of the present invention.

[0019] The APM monorail vehicle 100 includes various operational sub-systems (not shown), such as the propulsion sub-system, the braking sub-system and the power sub-system, among many others. These sub-systems all work together to drive and control the motion of the vehicle 100 along the monorail track 110. Since the functionality and various possible implementations of these sub-systems are well known to those skilled in the art, and are not critical to the present invention, they will not be described in further detail.

[0020] In the example shown in FIG. 1, the APM monorail vehicle 100 is composed of three inter-connected cars 120, each of which is provided with a suspension sub-system, as will be described in further detail below. Note that the APM ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com