Flexible conveyance system

A transportation system, flexible technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve problems such as lack of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

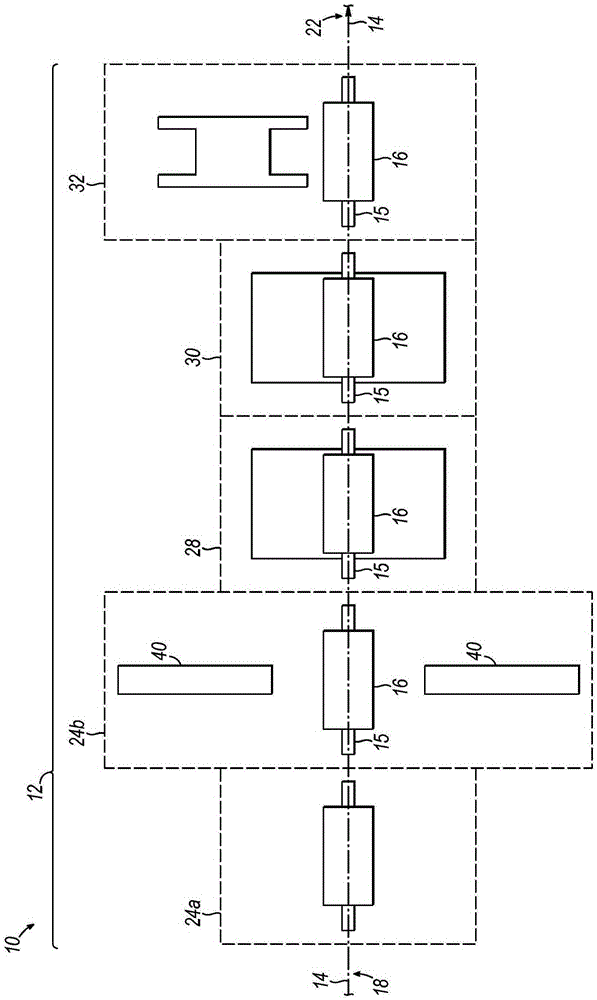

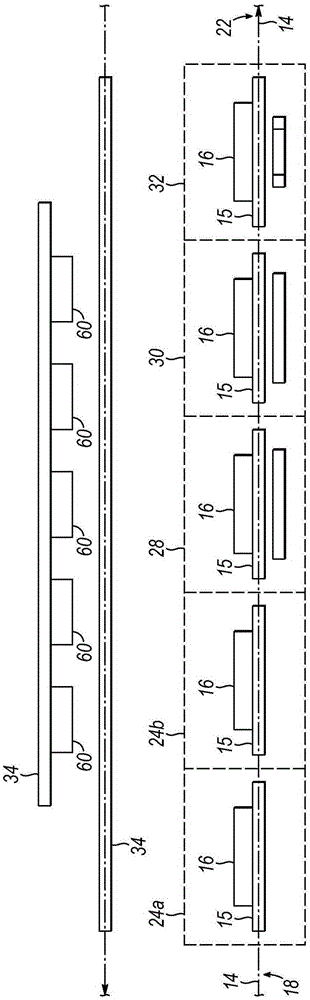

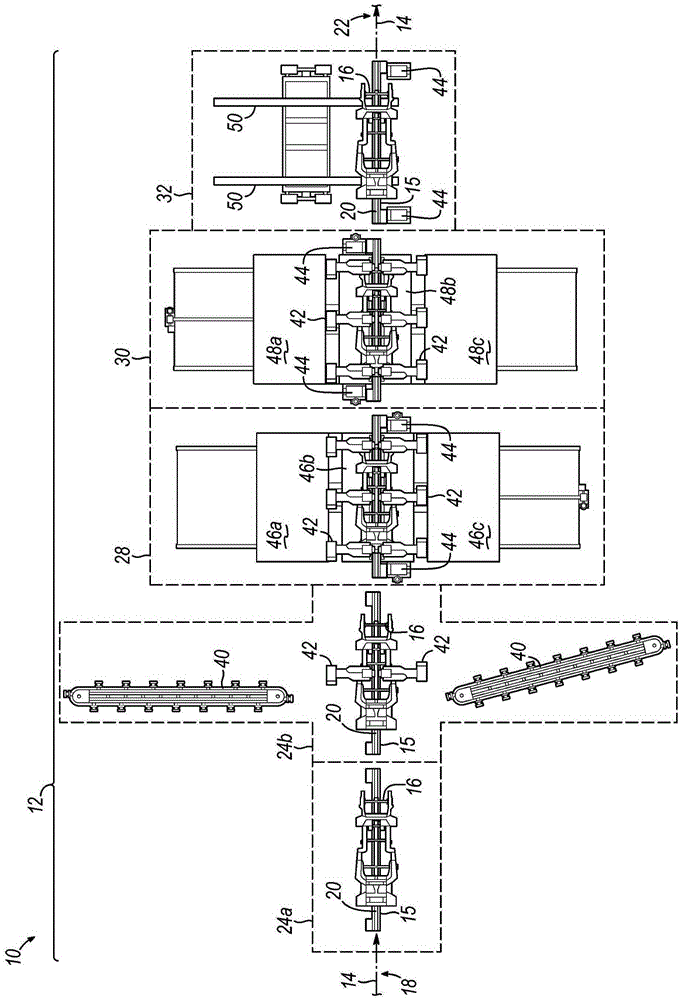

[0041] figure 1 is a schematic illustration of an exemplary, flexible inverted transport system 10 in accordance with the principles of the present invention. The plurality of stations 12 are configured to machine and assemble a plurality of components and subassemblies, such as vehicle bodies.

[0042] System 10 includes tracks 14 that transport components between stations 12 . Carrier 16 (refer to below Figure 5 with Figure 9 described more specifically) cooperates with the track 14 and acts as a foundation to receive the various components and subassemblies. Carrier 16 is introduced at the beginning of line 18 and passes through a plurality of band segments 20 (refer to Figure 6-Figure 8More specifically described) transportation, these belt segments 20 are arranged below the track 14 . It was observed that several configurations of belt 20 provided acceptable results. Two important design characteristics of belt 20 include resistance to elongation, and application...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com