Friction drive conveyor

A technology of friction drive and conveying device, which is applied in the direction of transportation and packaging, conveyors, motor vehicles, etc., and can solve the problems of increasing the number of motors used for driving the friction drive wheel, increasing the cost, delaying the stop period, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

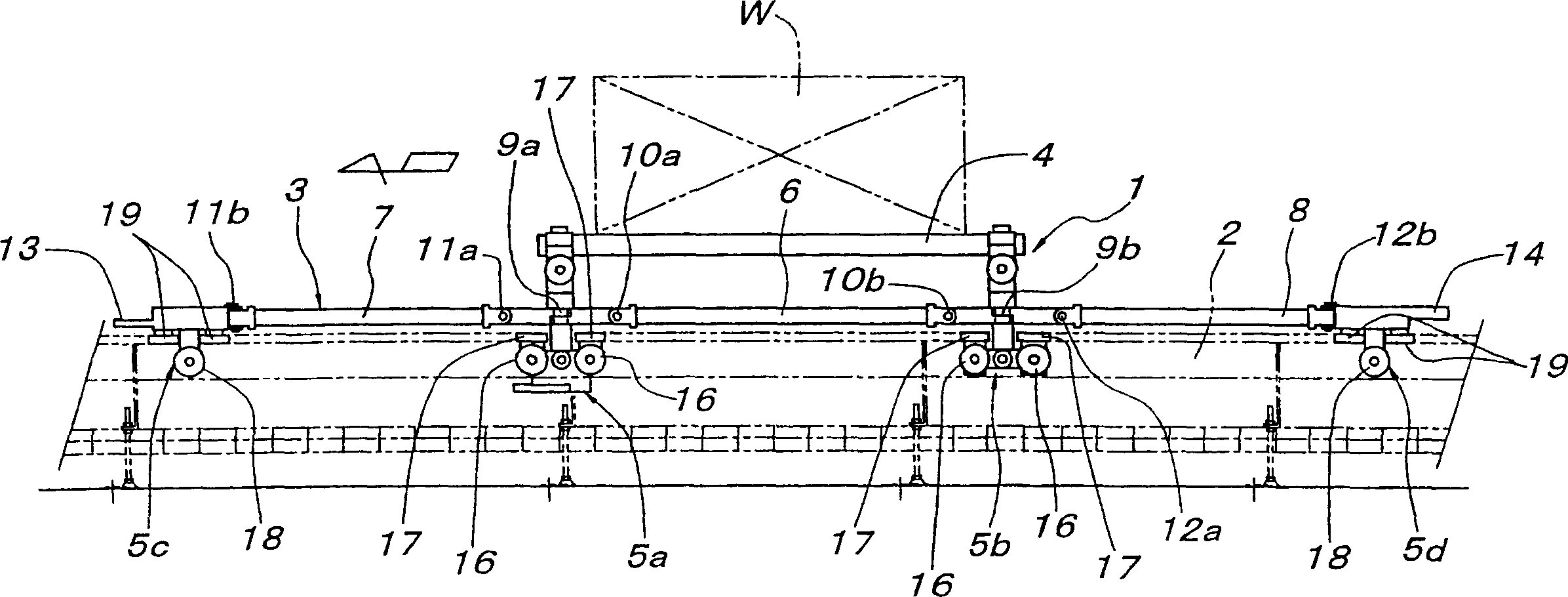

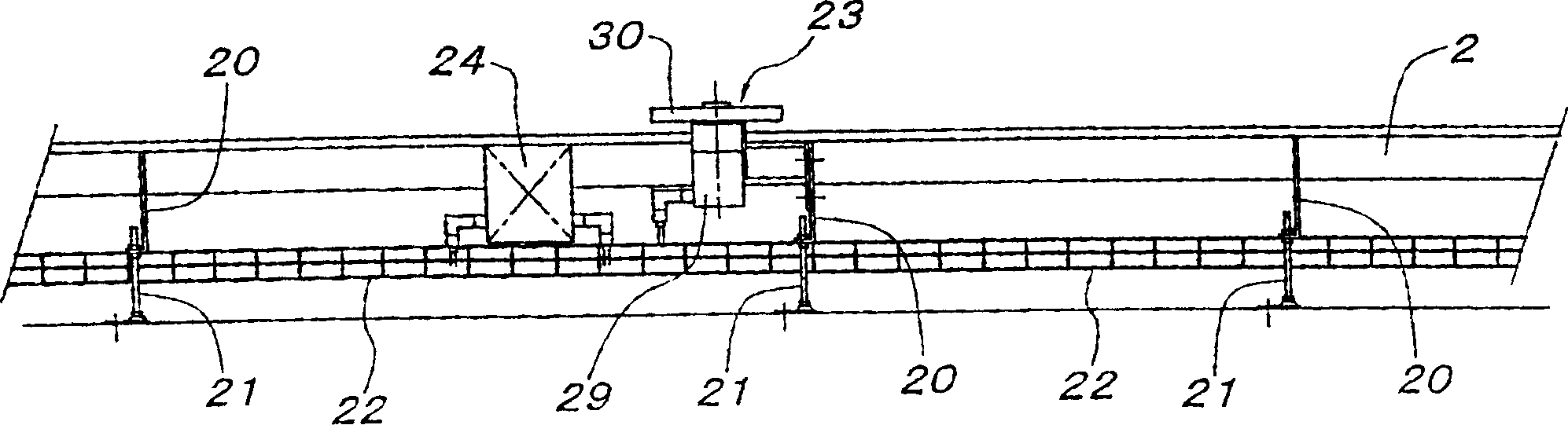

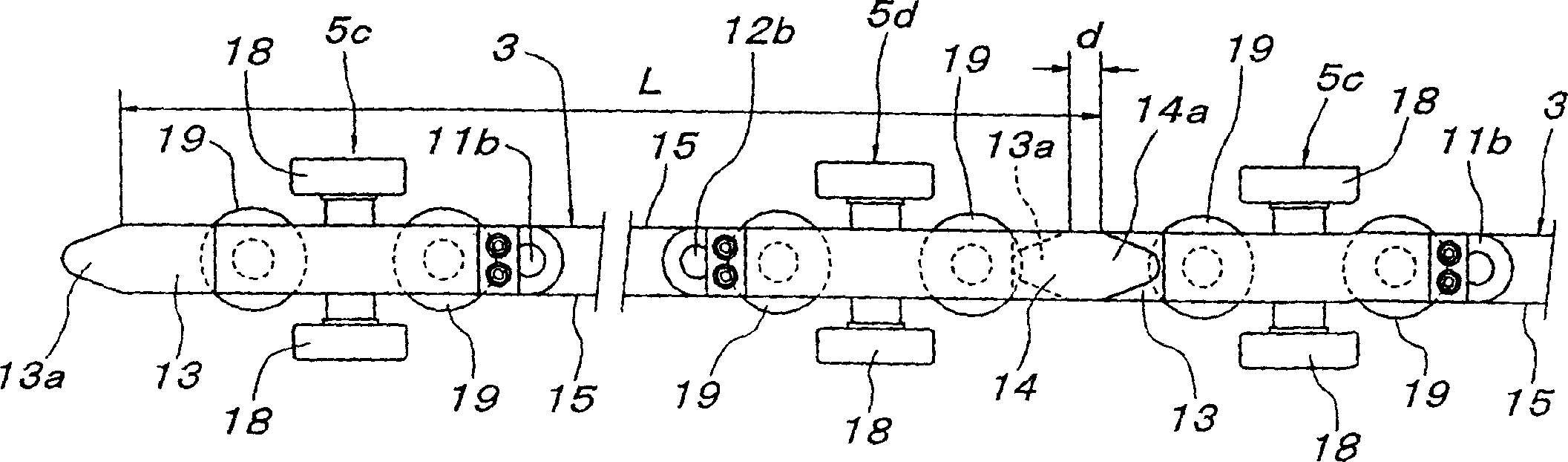

[0052] Below according to accompanying drawing, preferred embodiment of the present invention is described, in Fig. 1~ image 3 Among them, reference numeral 1 denotes a traveling body for transportation of the floor traveling trolley type, and reference numeral 2 denotes a guide rail for supporting and guiding the traveling body 1 for transportation. The running body 1 for transportation includes a loading bar 3 parallel to the traveling direction, a cargo platform 4 that supports the object W to be transported, and four tackles 5 a to 5 a that support and guide the loading bar 3 . 5d.

[0053] The loading bar 3 is composed of a middle loading bar 6 , a front loading bar 7 and a rear loading bar 8 , and the middle loading bar 6 connects two front and rear load blocks 5 a and 5 b in the middle that support the front and rear ends of the cargo platform 4 . , the front side loading bar 7 connects the front end guide block 5c and the front side load block 5a, and the rear side lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com