Friction drive trolley conveyor

A friction drive, suspension technology, applied in conveyors, mechanical conveyors, elevated railway systems with suspended vehicles, etc., can solve problems such as inconvenience, general products do not have appropriate structures, etc., to reduce costs and achieve small The effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure and characteristics of the suspension friction transmission conveyor proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. And its effect, detailed description is as follows.

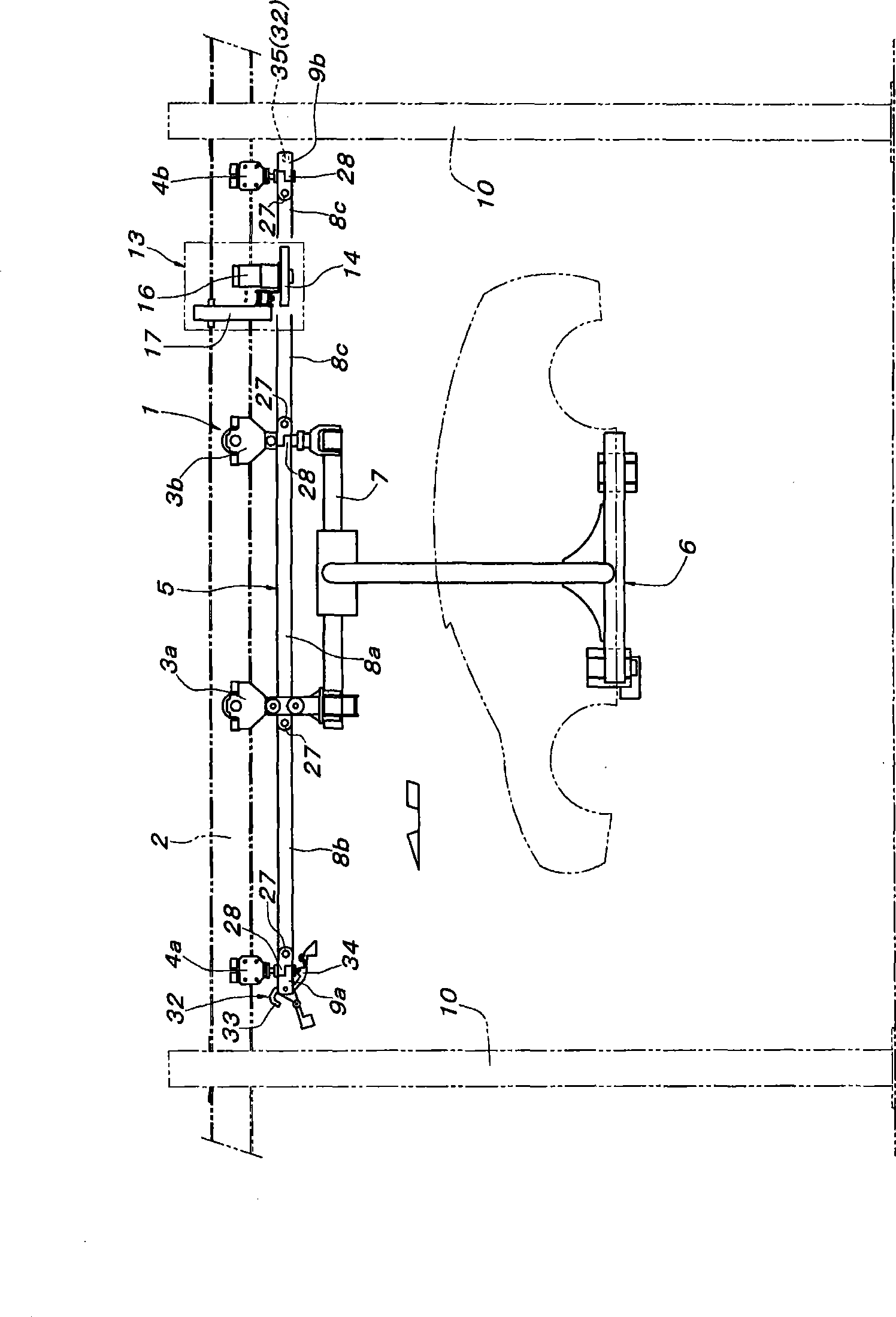

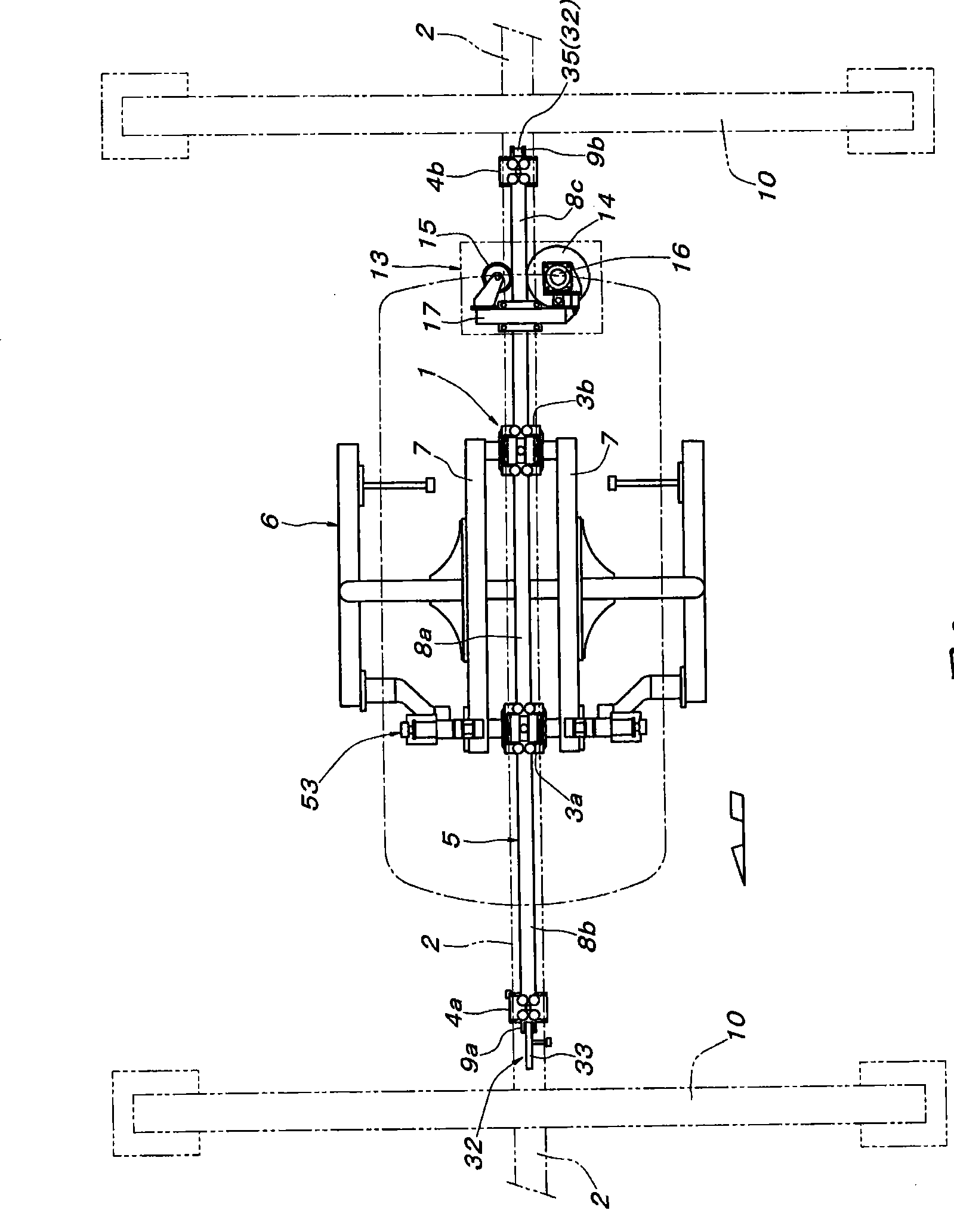

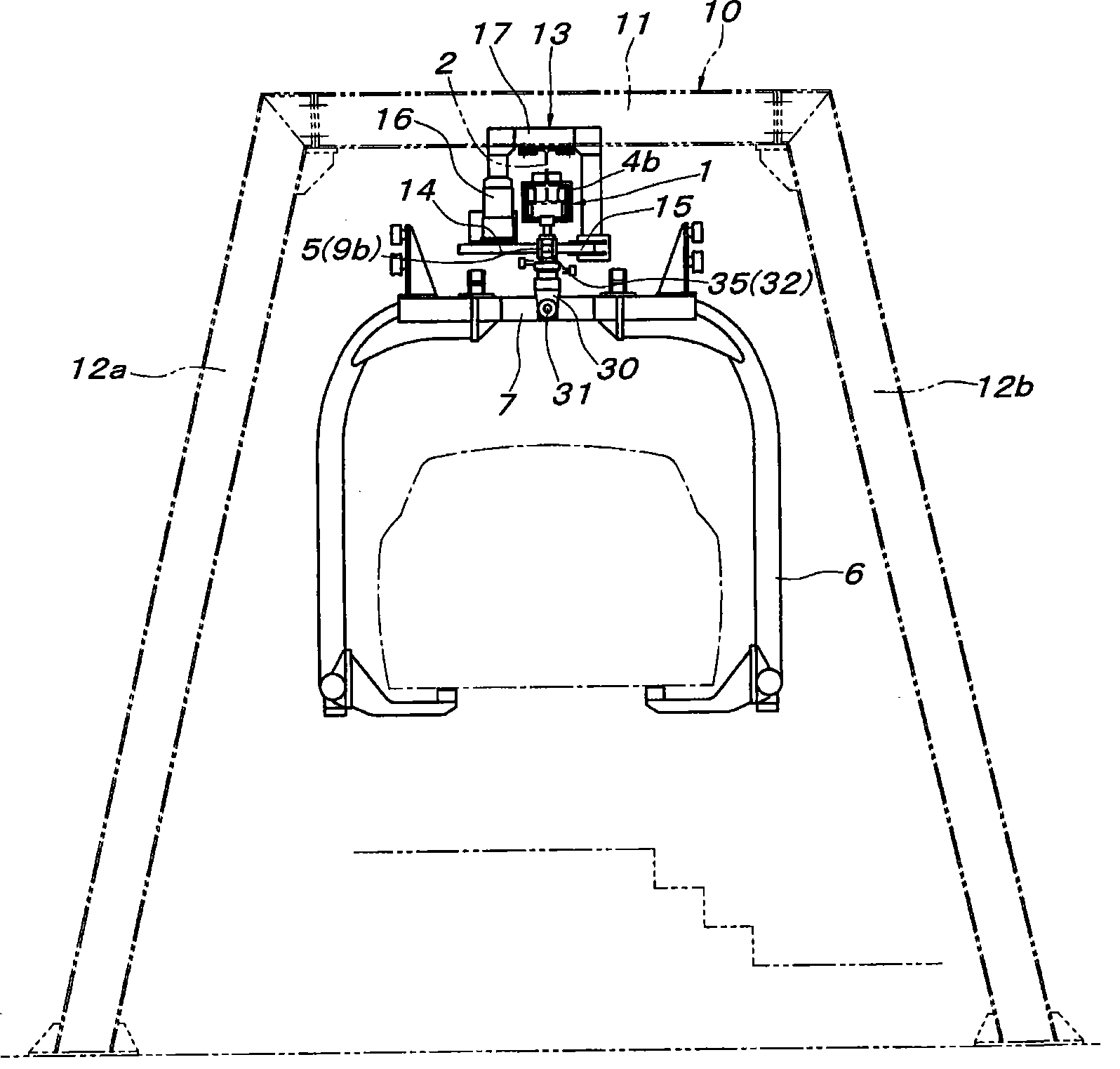

[0077] The specific embodiment of the present invention will be described below according to the accompanying drawings. Figure 1 ~ Figure 3Among them, the mobile body 1 for conveying is composed of four trolleys, that is, a pair of front and rear load trolleys 3a, 3b located in the middle and free trolleys 4a, 4b located at the front and rear ends, and is lifted by these four trolleys. The hanging load bar 5 is composed of a hanger 6 as a support for the object to be conveyed. Among them, four trolleys are connected to the guide rails 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com