Calcium carbide conveyor train

A technology of trains and calcium carbide, applied in the field of calcium carbide production, can solve problems such as high labor costs, many control points, and multiple safety hazards, and achieve the effects of improving cooling effects, continuous production operations, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

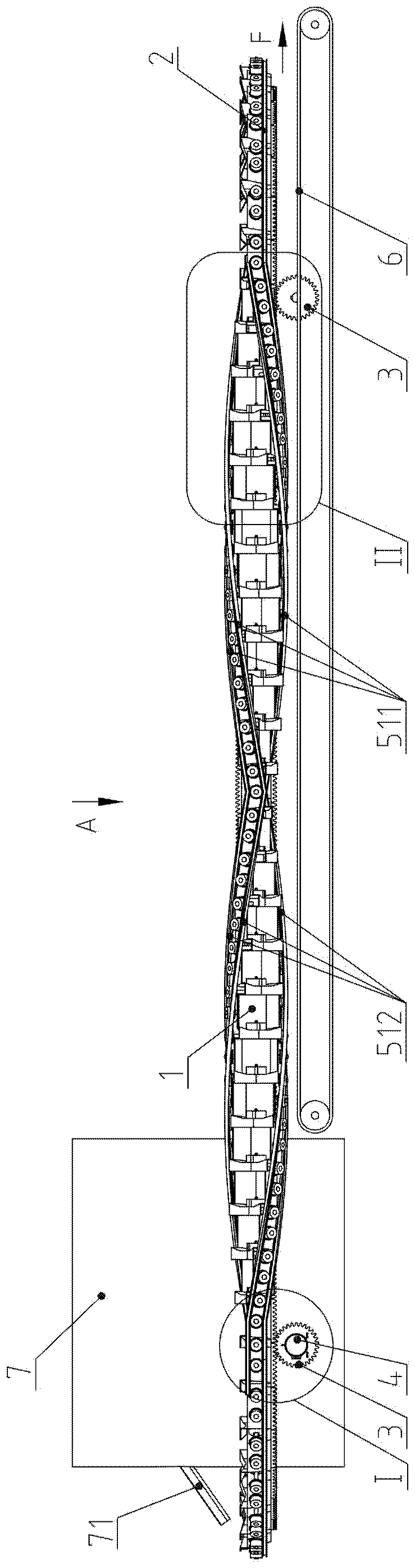

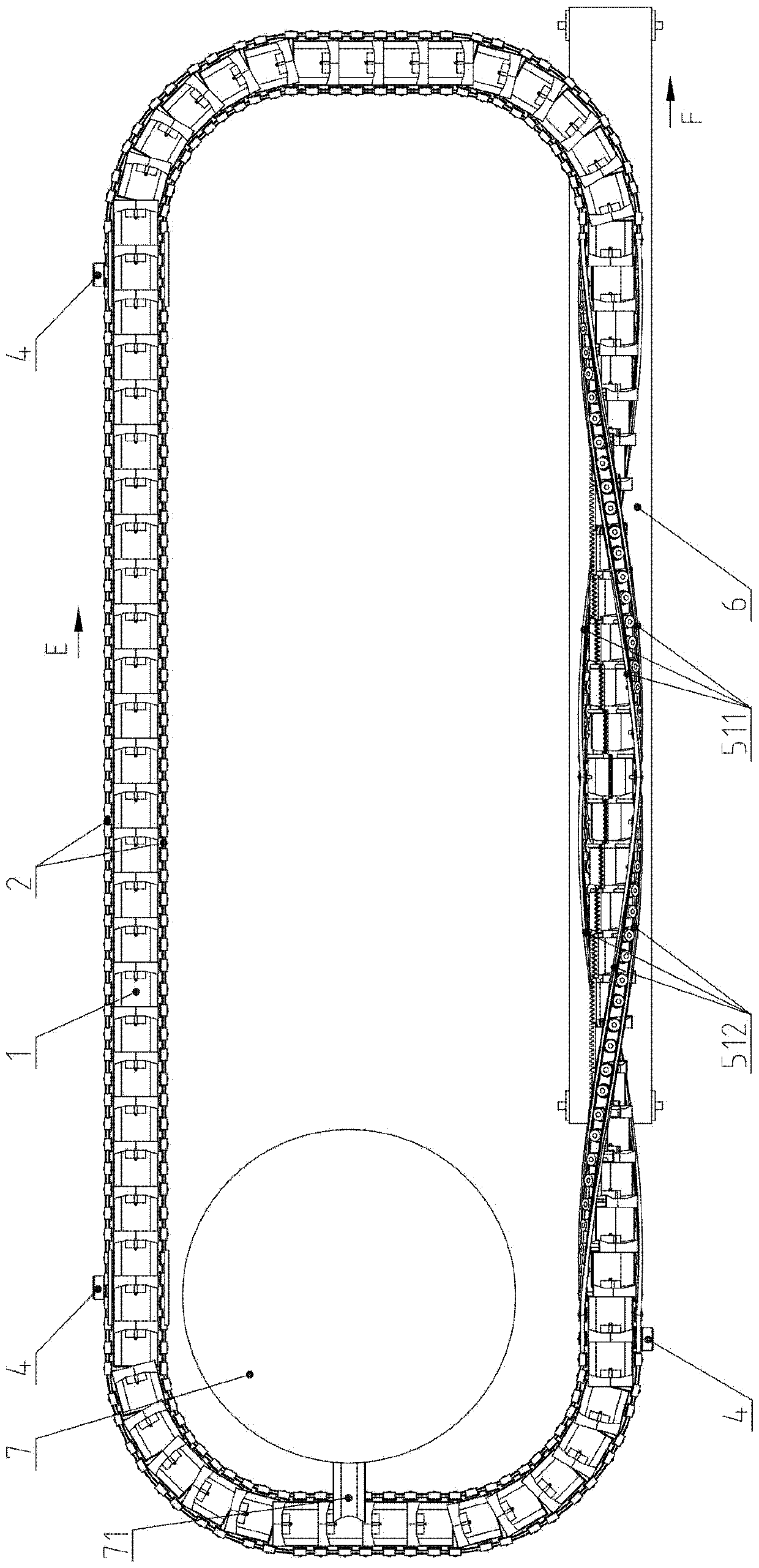

[0048] Embodiment 1: see Figure 1 to Figure 14 .

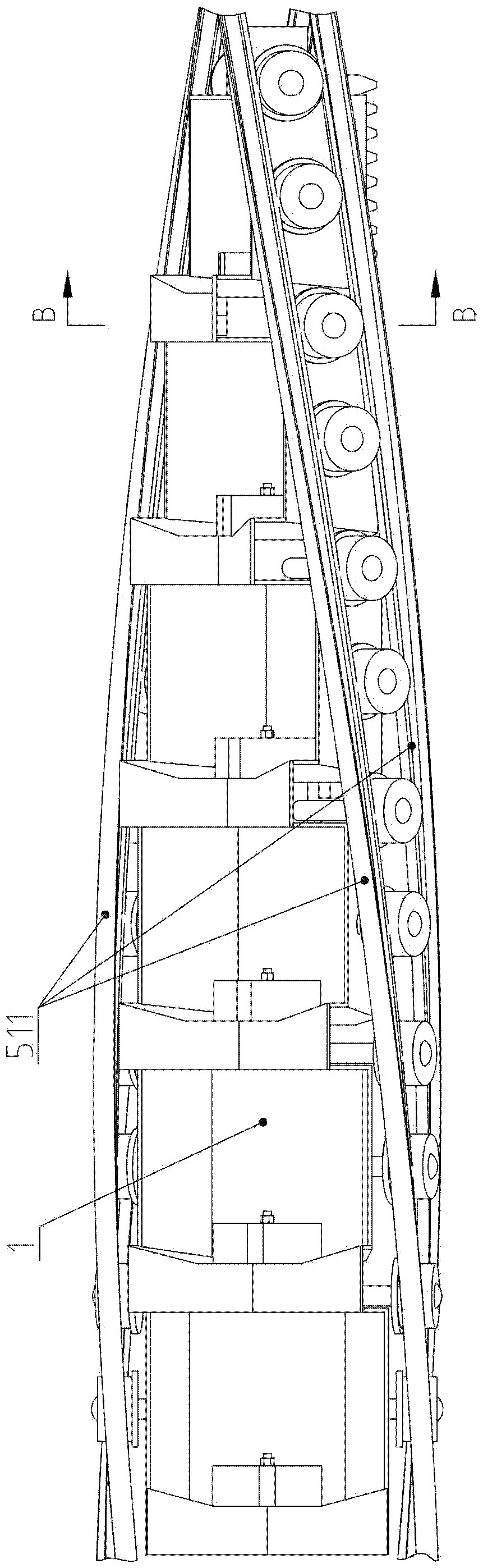

[0049] A calcium carbide conveying train, comprising a circular train 1, a horizontal track 2, a left-handed half-circle spiral track 511, a right-handed half-circle spiral track 512 and a driving device;

[0050] Horizontal track 2 refers to the track whose gauge remains unchanged and is laid on the same level; left-handed half-circle spiral track 511 refers to a 0.5-circle track laid along the direction of the left-handed helix with the gauge always kept constant; The circle spiral track 512 refers to a 0.5 circle track laid along the direction of the right-handed helix with the track gauge always kept constant, such as Figure 1 to Figure 4 As shown; the horizontal orbit 2, the left-handed half-circle spiral orbit 511 and the right-handed half-circle spiral orbit 512 are connected end to end to form a smooth closed-loop orbit;

[0051] The circular train 1 includes a plurality of calcium carbide trolleys 100, and the cal...

Embodiment 2

[0071]Example 2: see Figure 15 .

[0072] A calcium carbide conveying train, comprising an open-loop train 170, a horizontal track 2, a full circle of spiral track 52 and a driving device; the full circle of spiral track 52 rotates around a horizontal axis in a left-handed direction and coils a full circle, and then connects end to end with the horizontal track 2 for common Form a smooth closed-loop track;

[0073] The open-loop train 170 includes a plurality of calcium carbide trolleys 100 connected end to end in a row, but does not form a closed loop;

[0074] Four groups of motor 4-gear 3 combinations are also provided, no matter which position the open-loop train 170 runs to, there will always be one or two groups of motor 4-gear 3 combinations meshing with it;

[0075] The calcium carbide trolley 100 rotates along the spiral track 52 for a full circle, and when it rotates half a circle, the opening faces downward, and the material inside is dumped out, and then continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com