Heavy Load Tyre

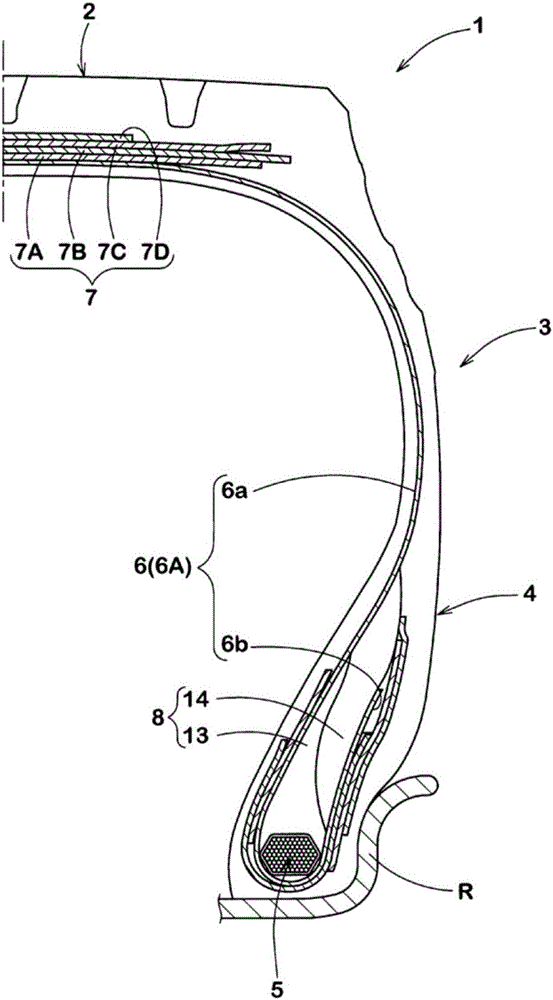

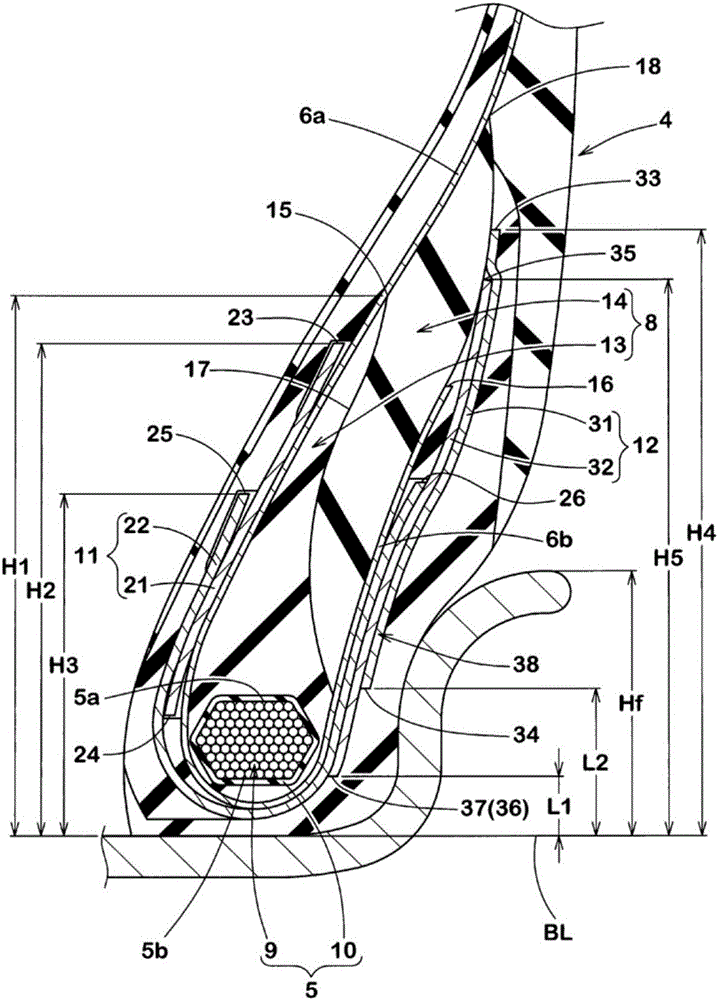

A technology for heavy loads and tires, which is applied to tire parts, tire edges, transportation and packaging, etc., and can solve problems such as tire delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

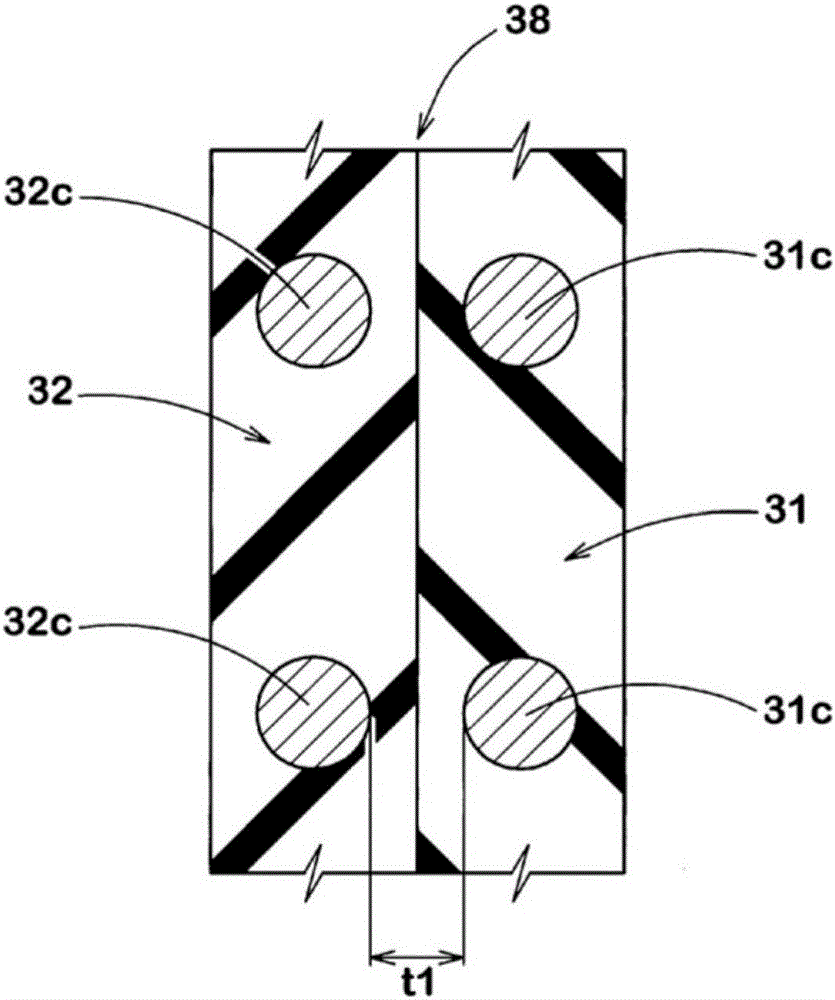

Method used

Image

Examples

Embodiment

[0073] Based on the specifications in Table 1, manufactured with figure 1 The basic structure of figure 2 , Figure 4 or Figure 5 The size of the bead part is 12.00R20 for heavy duty tires. As a comparative example, manufacture such as Figure 6 Shown is a heavy duty tire having a bead portion provided with only the first reinforcing portion. The durability of the bead portion of each test tire was tested. Common specifications and test methods for each test tire are as follows.

[0074] Install the rim: 20×8.50V

[0075] Tire internal pressure: 850kPa

[0076]

[0077] The above-mentioned test tires were run on a roller testing machine under the following conditions, and the running distance before the bead portion was damaged was measured. As a result, the value of Comparative Example 1 was assumed to be 100, and the larger the value, the better the durability of the bead portion.

[0078] Speed: 20km / h

[0079] Longitudinal load: 73.46KN

[0080] Test results...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com