Vehicle strut tower support reinforcing structure

A technology for strengthening structures and struts, which is applied to superstructures, vehicle parts, superstructure subassemblies, etc., can solve problems such as increased cost and weight, and increased number of parts, so as to improve bending rigidity and compression rigidity, and prevent relative Displacement, the effect of securing the steering stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

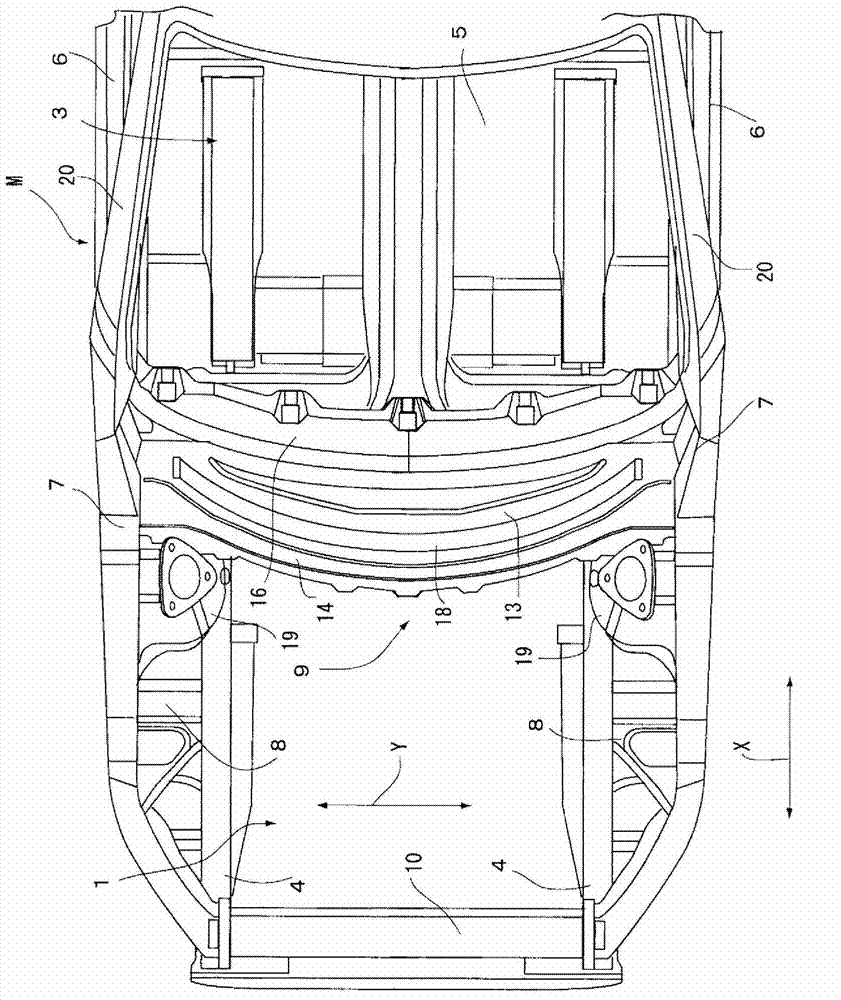

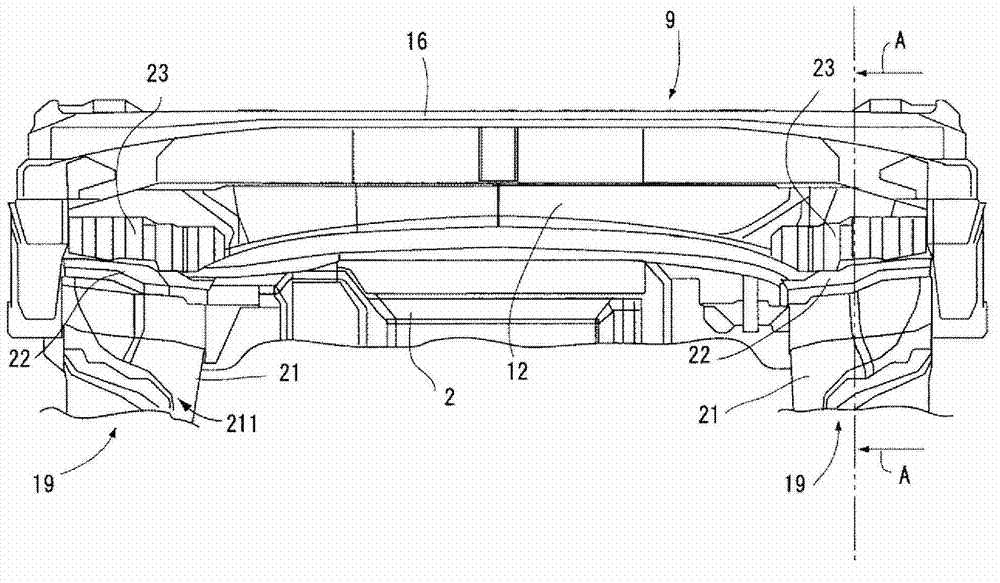

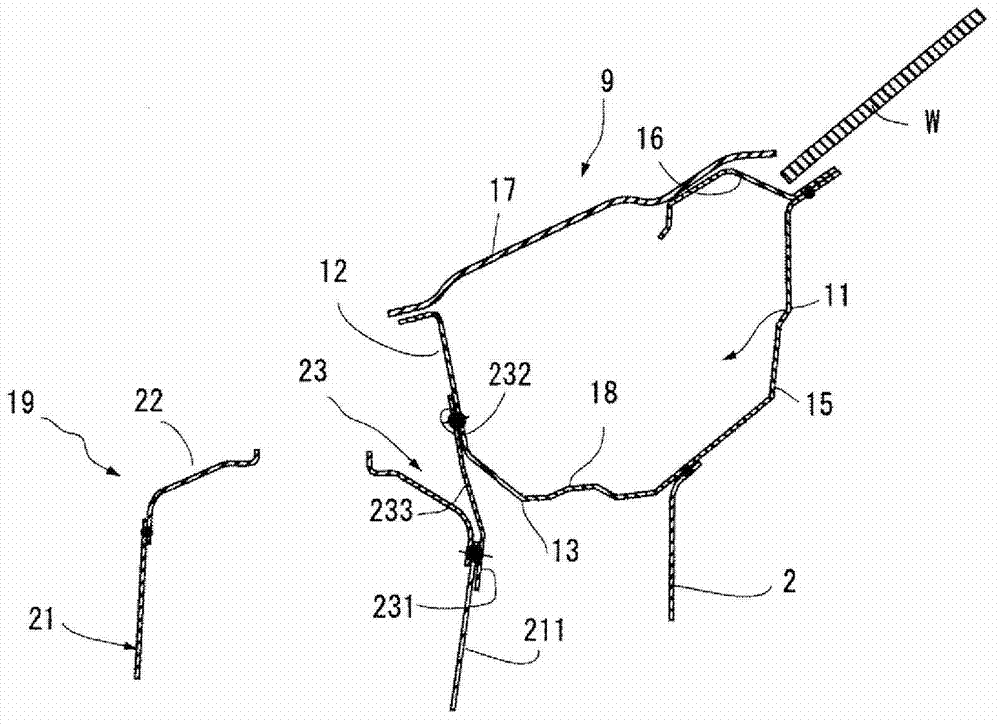

[0031] Refer to the following figure 1 The vehicle front body M to which the vehicle strut tower support reinforcement structure according to the first embodiment of the present invention is applied will be described. An engine compartment 1 is arranged at the front of the vehicle, and a vehicle compartment 3 is formed behind the engine compartment 1 with an instrument panel 2 interposed therebetween. On both left and right ends of the engine compartment 1 , long side beams 4 are arranged side by side along the front-rear direction X, and the rear ends of the two side beams 4 are welded to the lower rear bent portion of the instrument panel 2 from below. Furthermore, the front end sides of the two side members 4 are welded to each other at a front-end cross member (not shown), thereby securing the front rigidity of the engine room. A front portion of a floor 5 is integrally joined to a rear end edge of a lower curved portion of the instrument panel 2 . The left and right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com