Flexible package having integrated slit member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

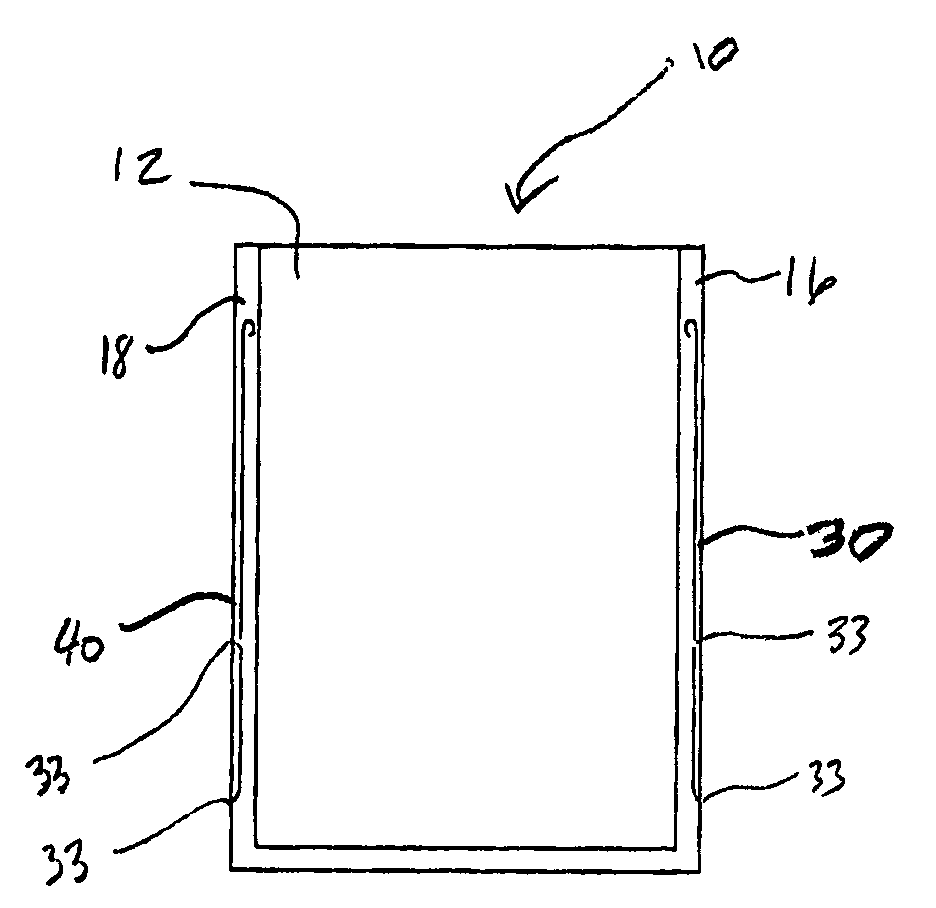

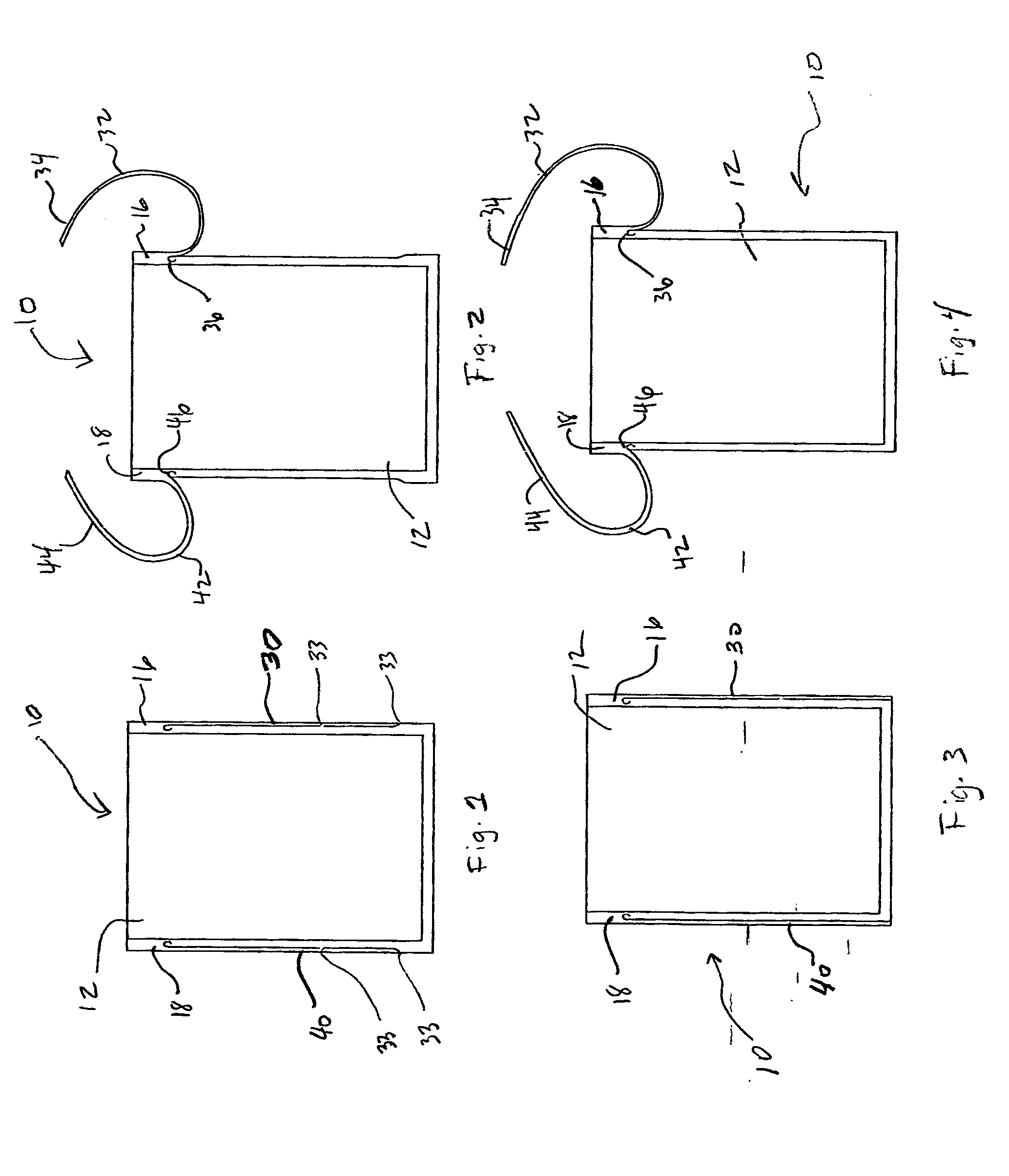

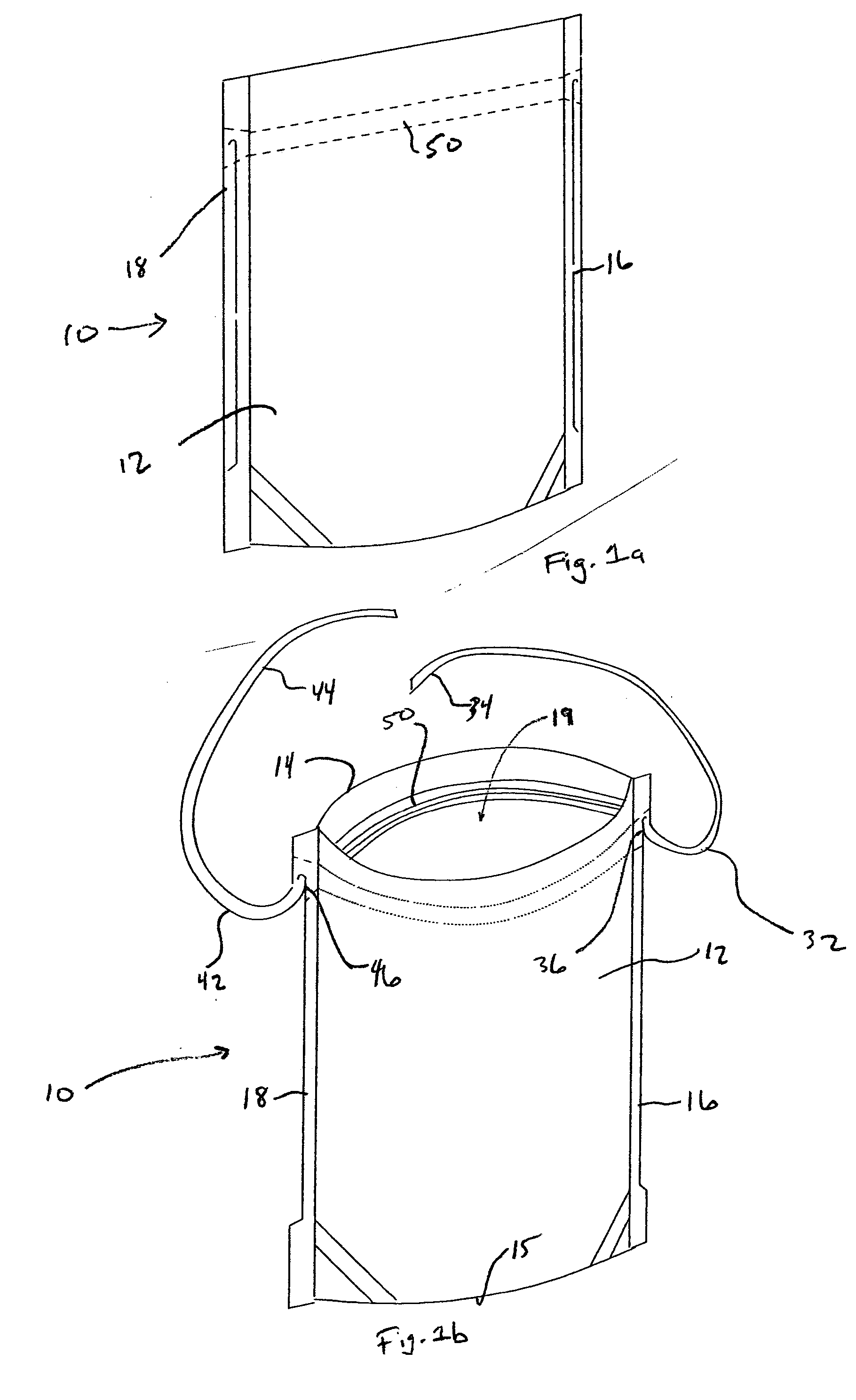

[0031] Referring to FIGS. 1-11, a flexible package 10 in accordance with the present invention is shown. The package 10 generally includes a front panel portion 12, a back panel portion 14 and at least one slit portion 30. Further, a bottom panel portion 15, gusseted or non-gusseted, can be included, especially in those embodiments defining a stand up package. The joining and / or shaping of the panel portions 12, 14, 15, generally define an inner cavity 19 having an adjustable internal volumetric capacity. The panel portions 12-15 are often referred to as “webs.”

[0032] The package panel portions 12-15 are generally constructed of flexible sheet material such as polyethylene, polyester, metal foil, polypropylene, or polyethylenes laminated with other materials such as nylon, polyester, and other materials known to one skilled in the art. To provide for higher barriers, embodiments can use combination layers or laminates of said materials, and material of the like. Generally, in such e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com