High-speed rail vehicle bogie

A high-speed track and bogie technology, applied in the field of bogies, can solve problems such as inferior suspension devices, poor line adaptability, and poor curve passing ability, so as to achieve accurate and reliable suspension parameters, reduce wheel and rail wear, and reduce springs. lower quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

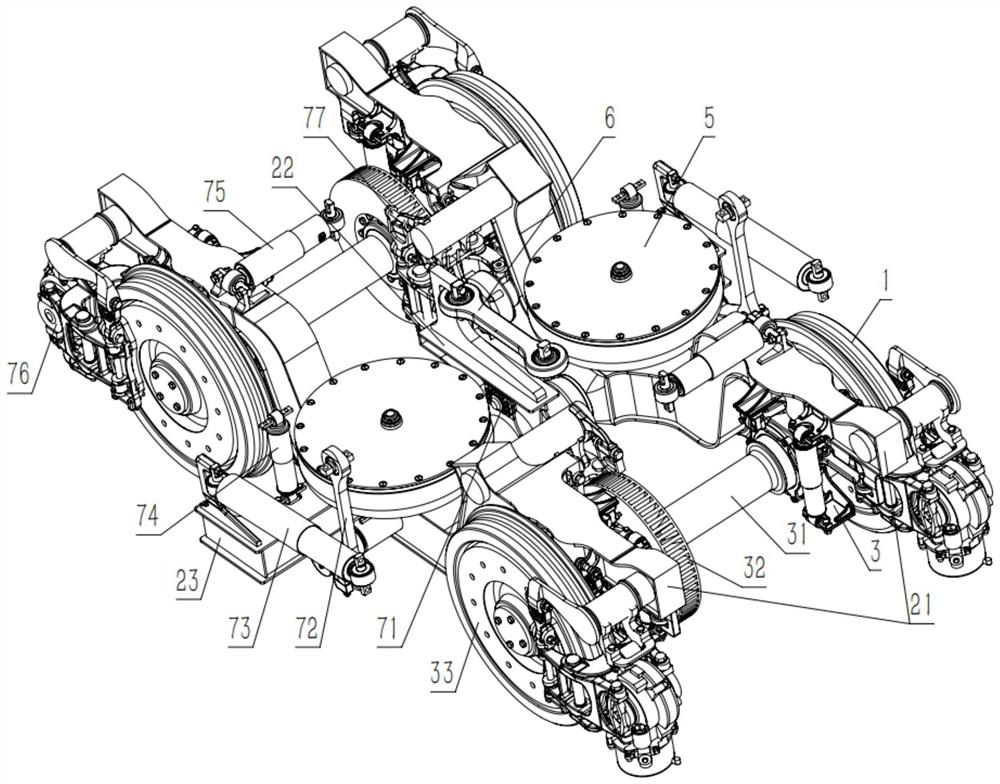

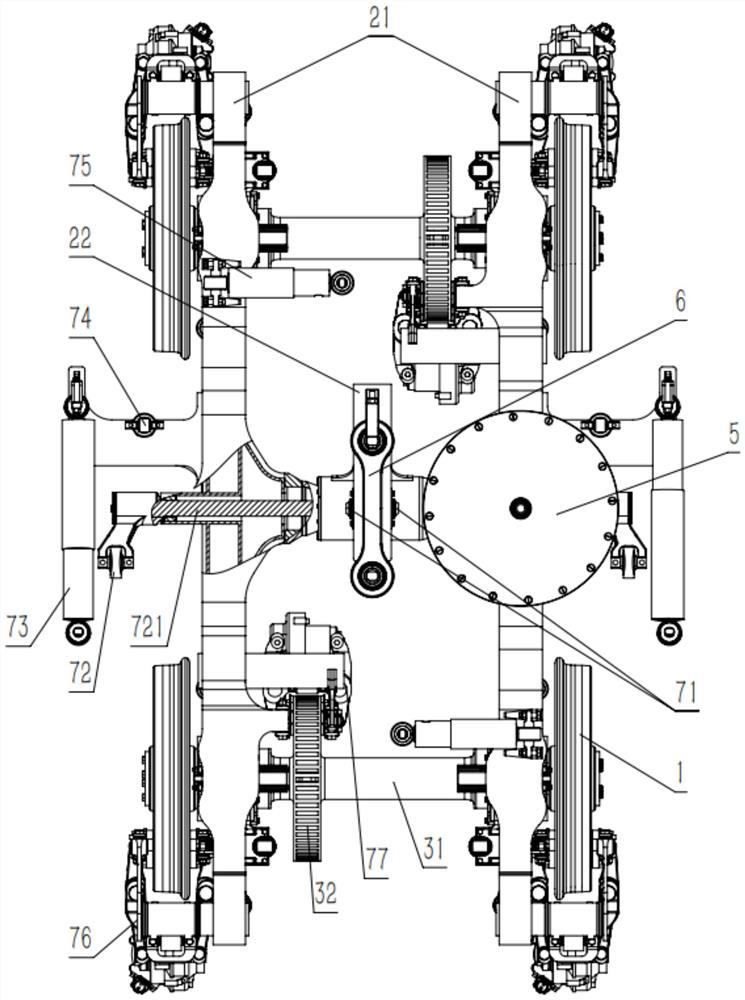

[0042] Such as Figure 1-8 As shown, the present invention provides a railway vehicle bogie, comprising:

[0043] A railway vehicle bogie comprising:

[0044] Wheel set, including wheel 1;

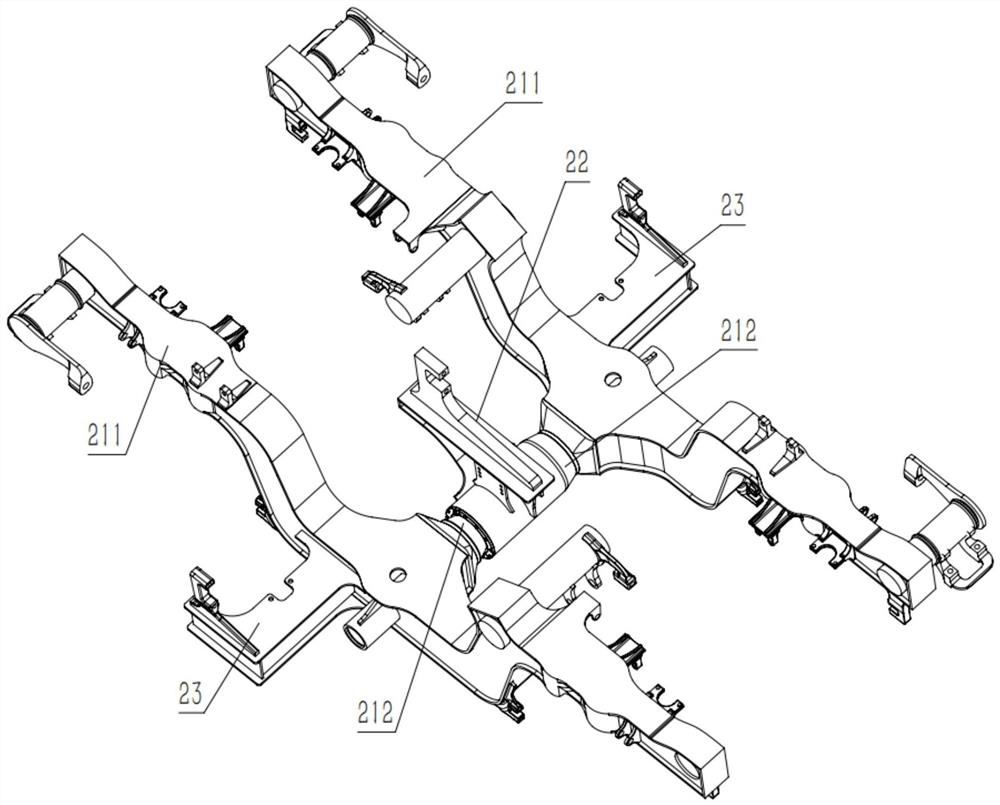

[0045] The hinged frame is located on the inner side of the wheel set and includes two T-shaped side beams 21, the central axes of the two T-shaped side beams 21 coincide, and the cylindrical beam 212 of one T-shaped side beam 21 extends into the other Inside the cylindrical beam 212 of the T-shaped side beam 21, two bearings 36 with a certain transverse span are arranged between the two T-shaped side beams 21, and the two bearings 36 can realize the horizontal axis between the two T-shaped side beams 21. Free rotation, so that the torsional rigidity between the two T-shaped side beams 21 is zero;

[0046] A series of suspension devices, including a series of spring parts 41 and a series of positioning parts 42, the series of positioning parts 42 include two longitudinal tie rods and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com