Production method of ultra-low anisotropic non-oriented silicon steel for oversize generator

A technology of oriented silicon steel and production method, which is applied in the direction of furnace type, furnace, heat treatment furnace, etc., can solve the problems that conventional equipment is not suitable for large-scale production process, the performance requirements of non-oriented electrical steel cannot be met, and the effect of non-oriented silicon steel is not obvious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with embodiment.

[0035] The method for producing ultra-low anisotropy non-oriented silicon steel for super-large generators according to the present invention includes: molten iron pretreatment, converter steelmaking, RH refining, continuous casting of molten steel into slabs, hot rolling, and normalization pickling , cold rolling, annealing, coating, finishing; among them,

[0036] The weight percent of the chemical composition of the non-oriented electrical steel is: C≤0.003%, Si 2.80-3.60%, Mn0.15-0.45%, P≤0.04%, Als 0.4-1.2%, S≤0.002%, and the rest is Fe and other unavoidable impurities;

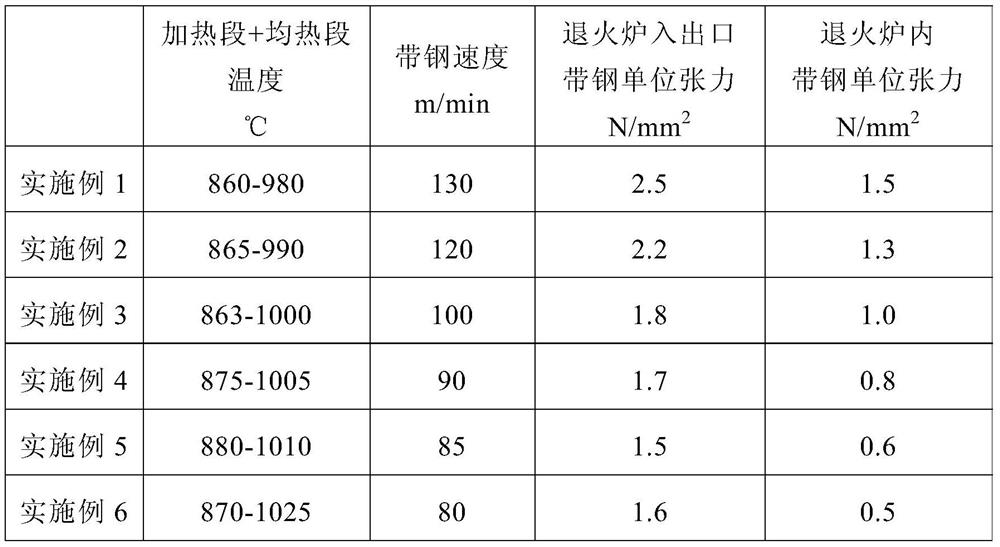

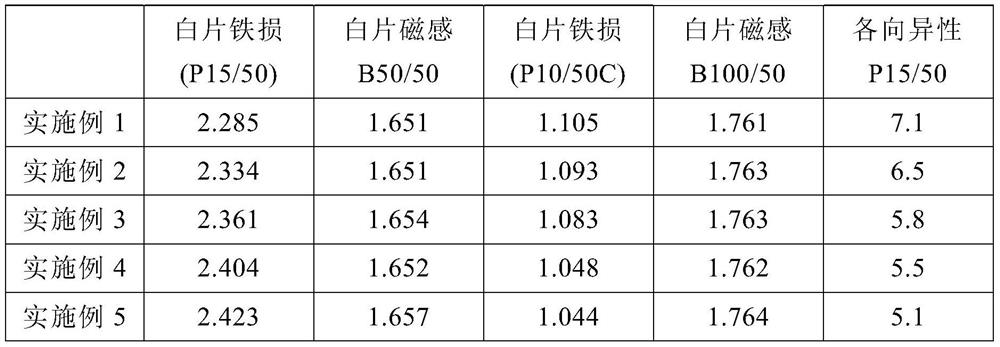

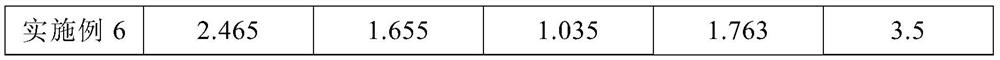

[0037] The annealing adopts a continuous annealing furnace, including a heating section, a soaking section, and a cooling section; the annealing temperature of the heating section and the soaking section is controlled at 860 to 1030° C., the strip speed is 90 to 130 m / min, and the strip at the entrance and exi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com