Partial cable-stayed bridge of steel truss web type concrete composite beam and construction method thereof

A part of cable-stayed bridge and concrete technology, applied in cable-stayed bridges, truss bridges, bridges, etc., can solve the problems of difficult grouting quality control, unreasonable economy, large earthquake response, etc., to broaden the applicability of earthquake conditions , broad application prospects, strong wind resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below, the present invention is described in detail with reference to accompanying drawing and embodiment:

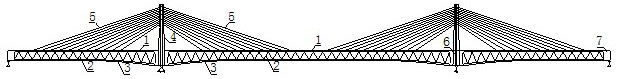

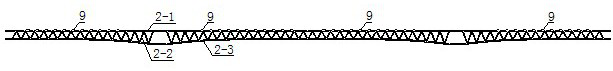

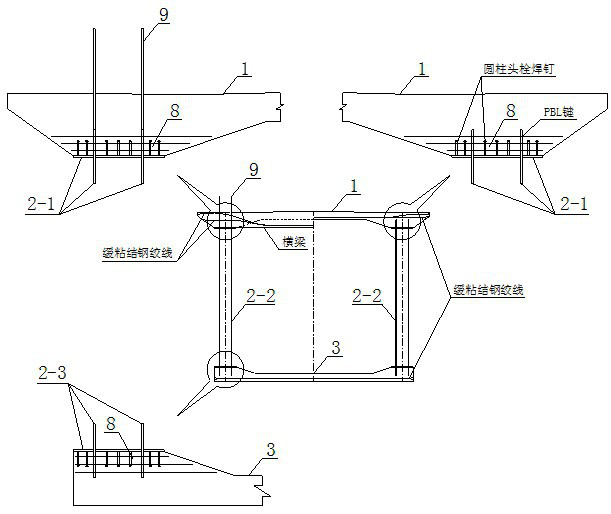

[0038] Such as Figure 1~6 As shown, a partial cable-stayed bridge of steel truss web type concrete composite girder comprises a main girder, and the main girder includes a tower girder consolidation area 6, a beam end area 7, and a steel truss web area, and the tower girder is consolidated A main tower 4 is arranged at the area 6, and a stay cable 5 is arranged between the main tower 4 and the main beam. The main beam includes a concrete roof 1 and a concrete floor 3. A steel truss web 2 connecting the two is provided.

[0039] The steel truss web 2 is a steel truss, and the steel truss web 2 is fixed to the concrete top plate 1 and the concrete bottom plate 3 through a steel-concrete joint structure 8 .

[0040] An anchor lug 9 is arranged on the main beam, and the stay cables 5 and the anchor lug 9 are connected through a steel anchor box 10 .

[0041] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com