Method for producing core rod by utilizing 30Cr3MoV steel as raw material

A raw material and mandrel technology, which is applied in the field of mandrel production, can solve the problems of difficulty in guaranteeing lateral impact toughness and high production cost, and achieve the effects of improving cooling speed and hardening depth, fast cooling speed and dense crystalline structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

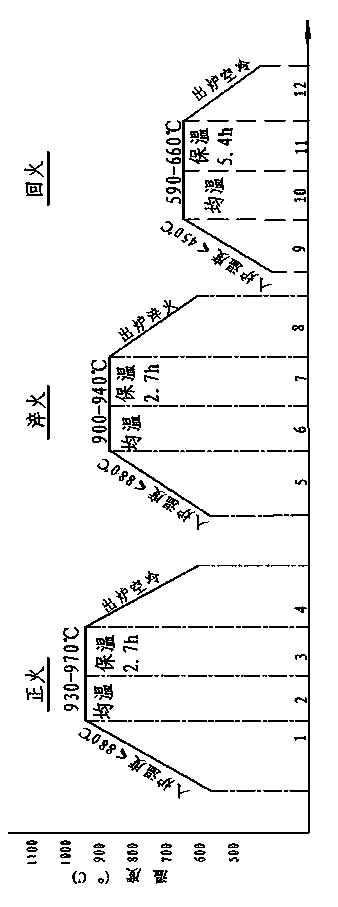

Method used

Image

Examples

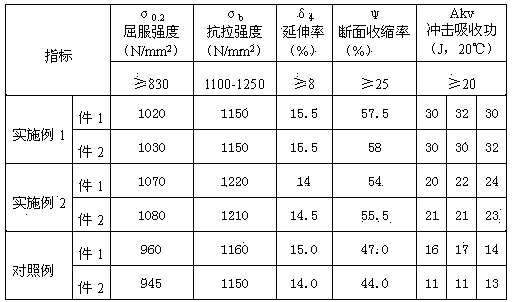

Embodiment 1

[0011] The mandrel steel type is 30Cr3MoV, which is made of material selection-refining-electroslag-forging-rough machining-heat treatment-finishing-chrome plating. After material selection, EAF+LF / VD refining method is adopted. Composed of the above steel scrap, return material, sponge iron, etc., tap after EAF oxidation, pre-deoxidize and partially alloy in the ladle, carry out LF / VD argon blowing refining, weakly stir before tapping, stirring time ≥ 15min, tap after calming Argon protection casting is used, and the electrode billet is hot-sent for electroslag remelting after demoulding. There is no slag groove larger than 3mm on the surface of the electroslag ingot. After demolding, it is hot-sent for forging. The composition is: C=0.28~0.33%, Si=0.55~0.70%, Mn=0.40~0.60%, Cr=3.00~3.30%, Mo=0.45~0.55%, V=0.20~0.30%, S≤0.008%, P≤0.012%; electroslag process control electroslag ingot chemical composition: C=0.28~0.33%, Si=0.45~0.65%, Mn=0.40~0.60%, Cr=3.00~3.30%, Mo=0.45~0.55%...

Embodiment 2

[0013] The mandrel steel type is 30Cr3MoV, which is made of material selection-refining-electroslag-forging-rough machining-heat treatment-finishing-chrome plating. After material selection, EAF+LF / VD refining method is adopted. Composed of the above steel scrap, return material, sponge iron, etc., tap after EAF oxidation, pre-deoxidize and partially alloy in the ladle, carry out LF / VD argon blowing refining, weakly stir before tapping, stirring time ≥ 12min, tap after calming Argon protection casting is used, and the electrode billet is hot-sent for electroslag remelting after demoulding. There is no slag groove larger than 3mm on the surface of the electroslag ingot. After demolding, it is hot-sent for forging. The composition is: C=0.28~0.33%, Si=0.55~0.70%, Mn=0.40~0.60%, Cr=3.00~3.30%, Mo=0.45~0.55%, V=0.20~0.30%, S≤0.008%, P≤0.012%; electroslag process control electroslag ingot chemical composition: C=0.28~0.33%, Si=0.45~0.65%, Mn=0.40~0.60%, Cr=3.00~3.30%, Mo=0.45~0.55%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com