Rolling technology of producing pipeline steel of extreme specifications through wide-heavy plate mill

A limit specification and plate rolling mill technology, applied in the field of steel rolling, can solve the problems of steel plate performance fluctuation, high scrap rate, poor plate shape, etc., achieve control of finishing rolling speed, high rolling hit rate and yield, and solve plate shape problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Select 1 piece of X65 pipeline steel, the thickness of the finished product is 8.8mm, and 10 pieces of 10mm thick steel plate have been rolled before rolling the target steel plate and the cooling water of the roller table is closed. The specific rolling process system of X65 is as follows:

[0017] (1) Dimensions of continuous casting slab: 150 thick * 1400 wide * 2700 long, rough plate size after rolling 8.8 thick * 2319 wide * 27665 long.

[0018] (2) The billet heating temperature is 1200°C, and the temperature of the upper and lower surfaces of the billet is 1213°C. The starting temperature of rough rolling is 1180°C, and the finishing temperature is 915°C.

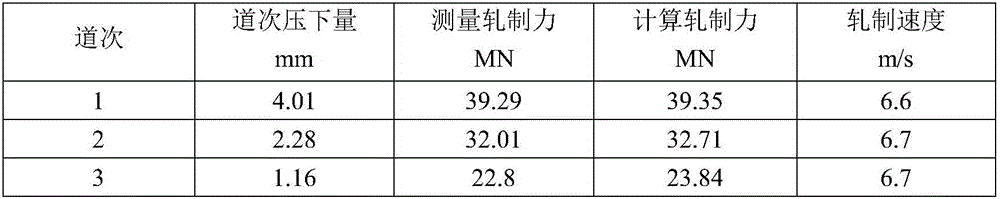

[0019] (3) The total number of rolling passes is 14, the thickness of the intermediate billet is 50mm, and the number of finishing rolling is 7. The rolling procedures and parameters of the last 3 passes of the finishing rolling stage are shown in Table 1 below.

[0020] Table 1 The rolling schedule and param...

Embodiment 2

[0026] Select 1 piece of X65 pipeline steel, the thickness of the finished product is 10mm, and 12 pieces of 11.5mm thick steel plates have been rolled before rolling the target steel plate and the cooling water of the roller table is closed. The specific rolling process system of X65 is as follows:

[0027] (7) Continuous casting slab size: 180 thick * 1800 wide * 3180 long, the rough plate size after rolling is 10 thick * 2626 wide * 38501 long.

[0028] (8) The billet heating temperature is 1205°C, and the upper and lower surface temperatures of the billet are 1213°C and 1210°C respectively. The starting temperature of rough rolling is 1170°C, and the finishing temperature is 870°C.

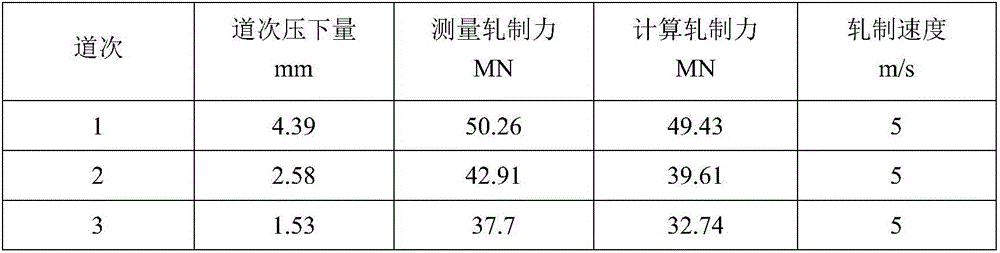

[0029] (9) The total number of rolling passes is 12, the thickness of the intermediate billet is 40 mm, and the number of finishing rolling passes is 6. The rolling procedures and parameters of the last 3 passes of the finishing rolling stage are shown in Table 2 below.

[0030] Table 2 The r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com