Wide and thick plate shape buckling and plate convexity control method

A control method and technology of plate crown, applied in the direction of profile control, metal rolling, manufacturing tools, etc., to achieve the effect of improving plate shape buckling, reducing plate crown, and reducing flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

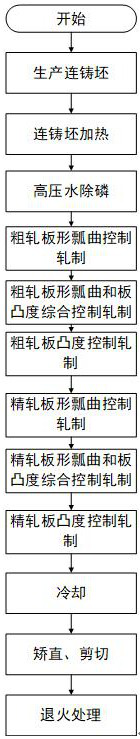

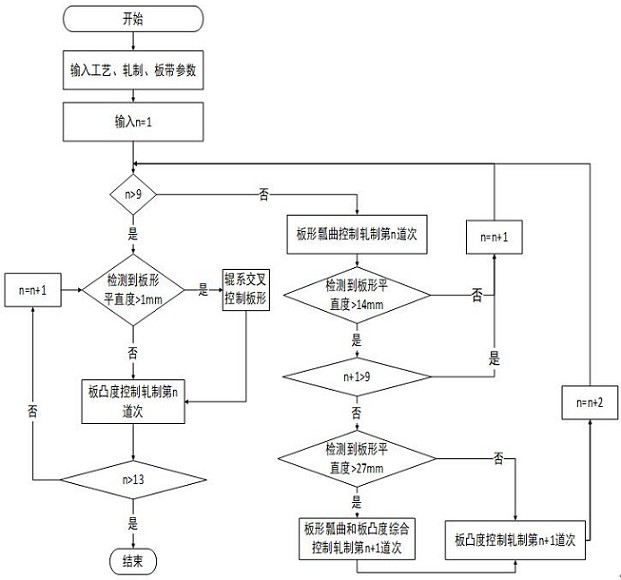

[0027] The invention proposes a method for controlling the curvature and convexity of wide and thick plates. The method includes CVC roll profile optimization and rolling process dynamic parameter adjustment.

[0028] CVC mill parameters are shown in the table below:

[0029] CVC mill parameters Value (mm) Maximum Roll Equivalent Crown 0.25 Minimum Roll Equivalent Crown 0.05 Equivalent crown of the roll when the roll shifting amount is 0 0 Maximum roll shifting amount of work roll 138 Work roll diameter 1031.45 Support roller diameter 2001.84

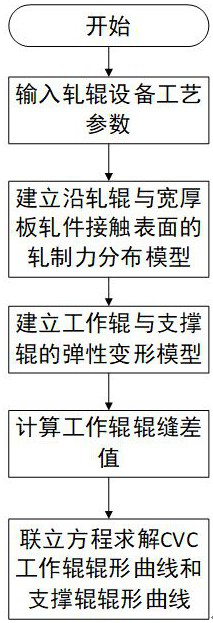

[0030] Such as figure 1 As shown, the CVC roll shape curve optimization includes the following steps: T1. Input the process parameters of the roll equipment; T2. Establish the rolling force distribution model along the contact surface of the roll and the wide and thick plate; T3. Establish the elastic deformation of the work roll and the backup roll Model; T4, calculate the gap differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com