Control method for walking-stopping type high-side-pressure sizing press

A control method, the technology of the fixed width machine, applied in the direction of tail end control, etc., to achieve the effect of improving control accuracy, improving rolling rhythm, and good control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

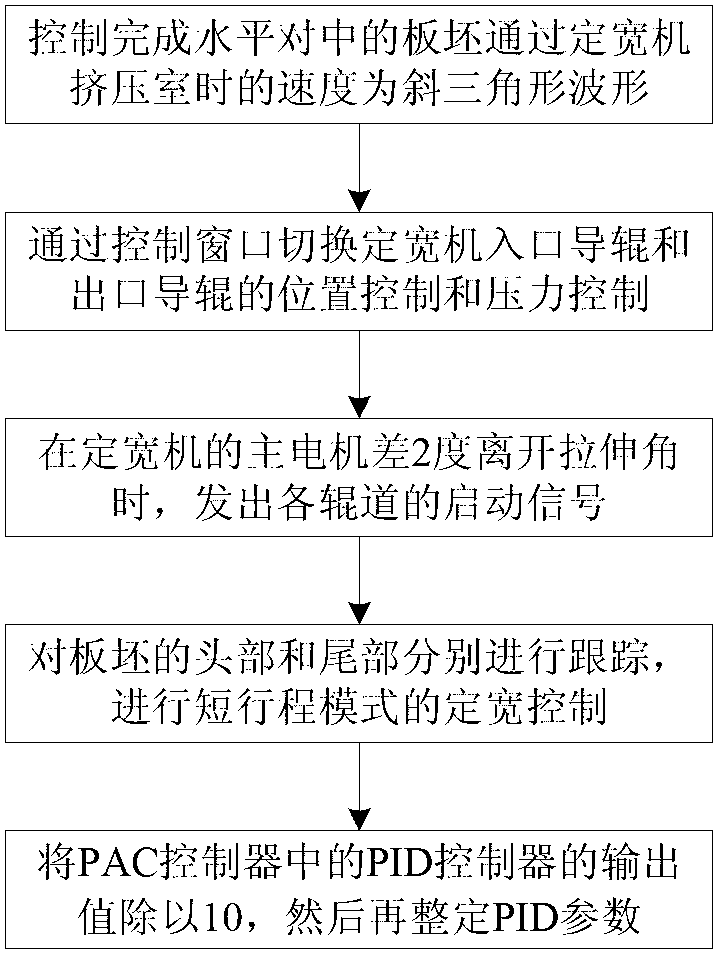

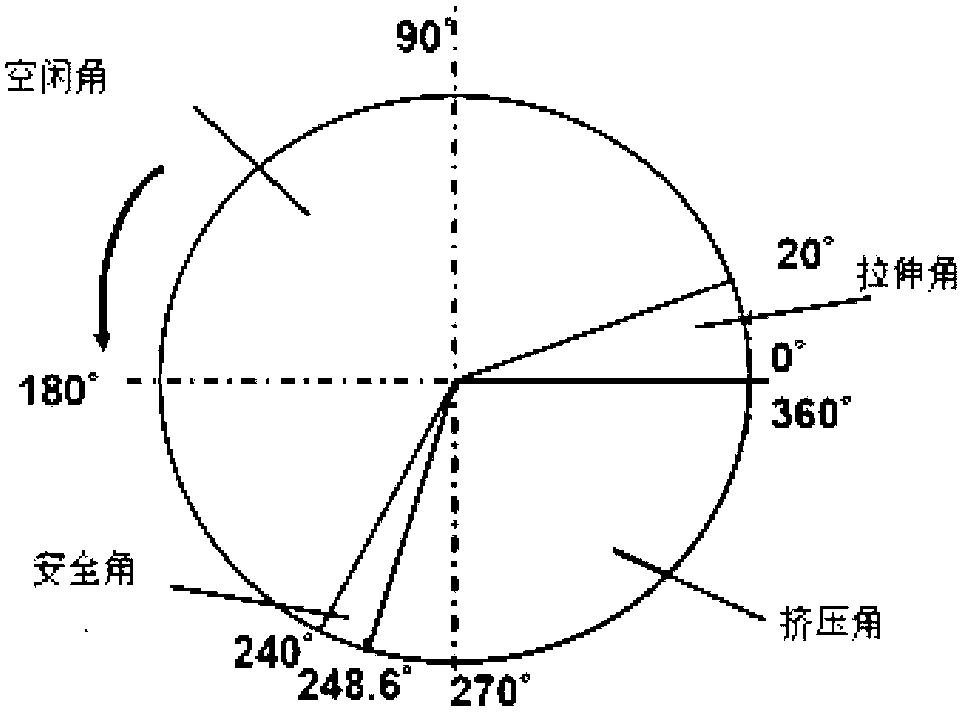

[0019] The present invention will be further described in detail with reference to the accompanying drawings and embodiments.

[0020] The control system of Shougang Jingtang 1580 hot-rolling fixed-width machine adopts the PAC controller RX7i CPE040 CPU of GE Company, the analog quantity function module of the main cabinet frame adopts the third-party template of MEN Company based on the VME bus, and the digital quantity template adopts the PAC RX7i of GE Company; The cabinet adopts VersaMax I / O station system of GE Company. The main process functions completed by the control system of Shougang Jingtang 1580 hot rolling sizing machine include high-pressure water billet descaling, slab conveying and pinching, slab centering, pressure balance of slab sizing device, hammer head replacement and process water cooling etc.

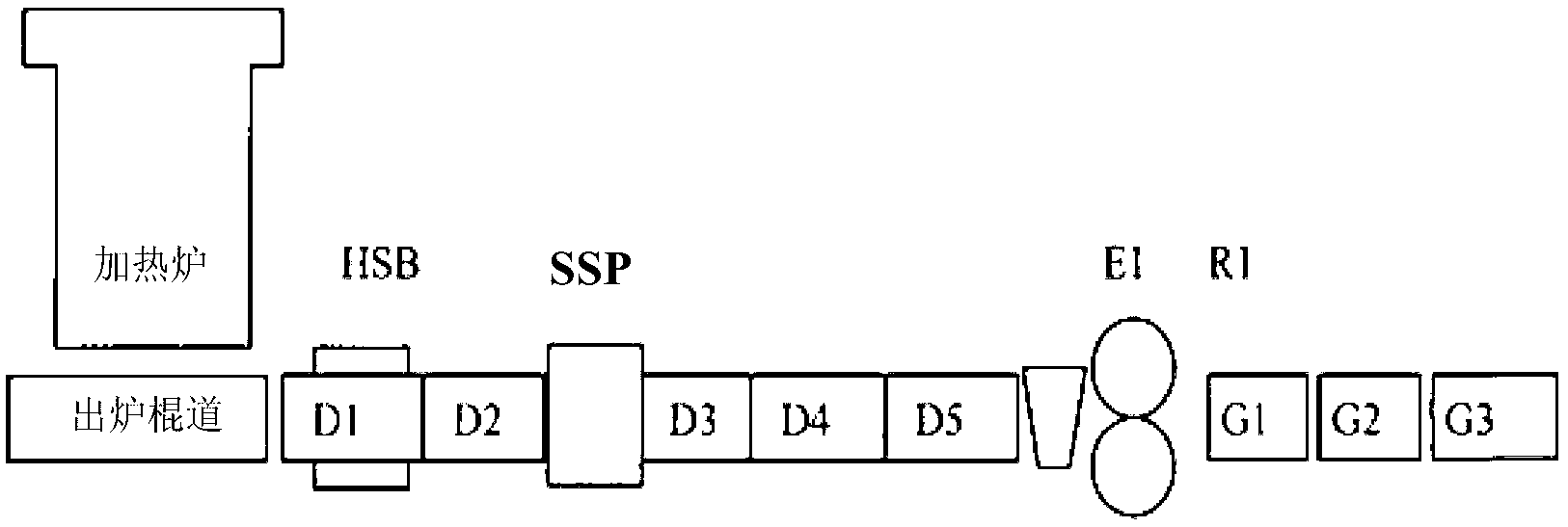

[0021] The hardware components involved in the control system of the sizing machine are arranged in the order of the upstream and downstream of the rolling lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com