Online control method for finish rolling temperature of precision rolling strip steel

A technology of finish rolling temperature and control method, which is applied in the direction of temperature control, etc., and can solve problems such as temperature fluctuation of strip steel, increase of plastic deformation heat, and inability to meet on-site control requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

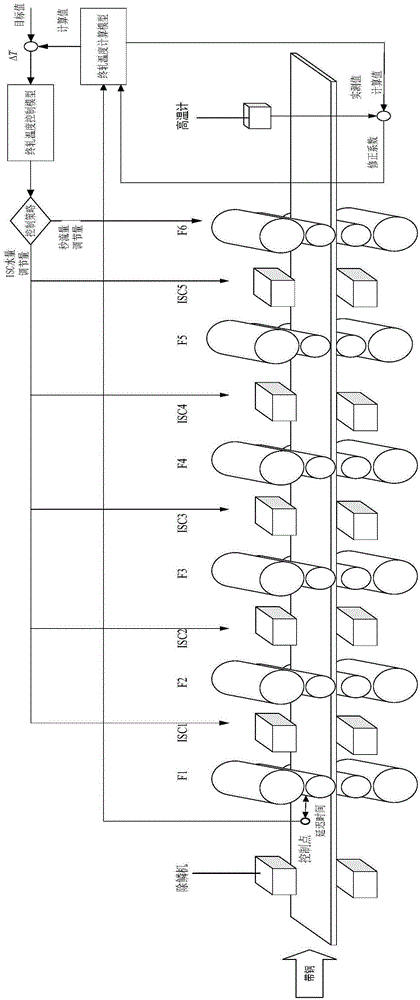

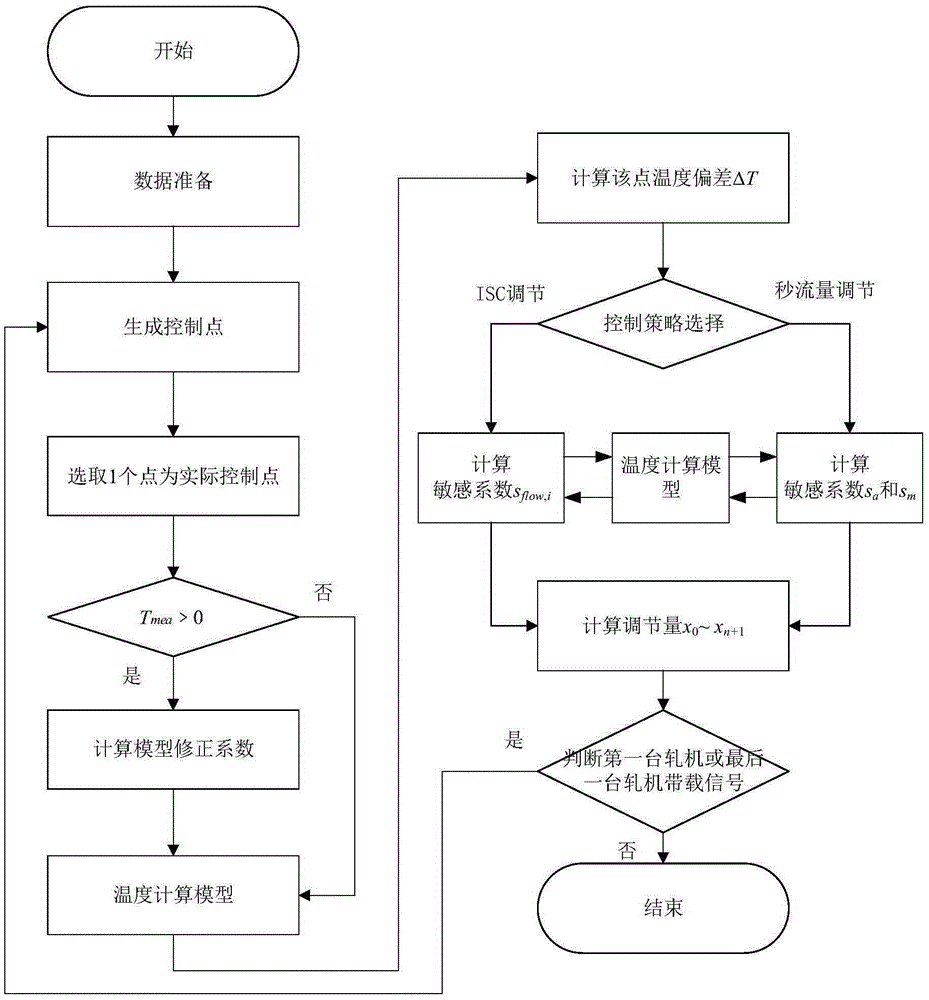

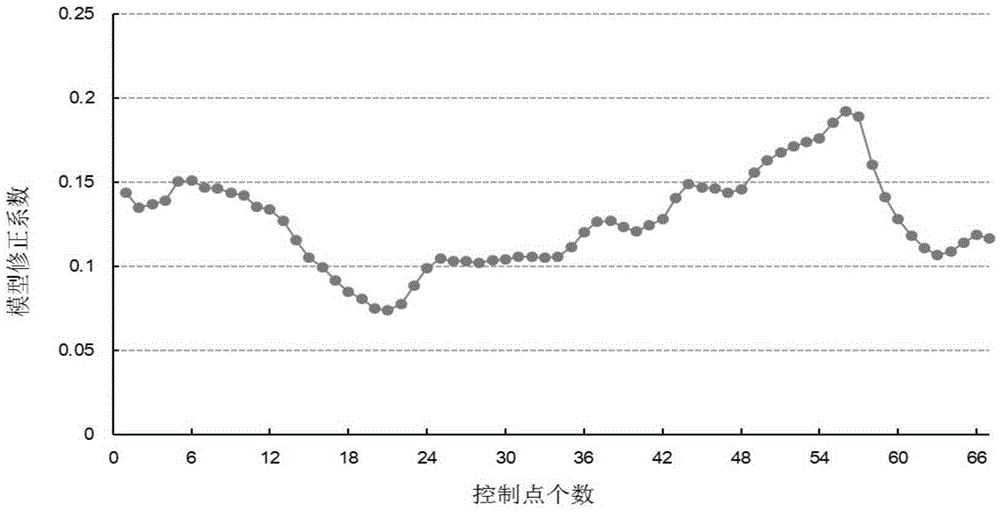

[0066] The embodiment of the present invention provides an on-line control method for the finish rolling temperature of the finished strip, using the actual process data and using the quadratic programming optimization algorithm to optimize the second flow adjustment amount of each control point or the cooling water amount adjustment amount between stands , used in the field of rolling process temperature control. The steel grade SDC01 is selected, the specification is 3.5*1270mm, and the cooling water between the stands is used to adjust the temperature control strategy of the final rolling as an example. The process parameters are shown in Table 1 and explained as follows.

[0067] Table 1 Process parameters of each pass of finish rolling

[0068]

[0069] 1) The strip generates several control points according to the control cycle in the length direction, such as figure 1 shown;

[0070] 2) According to the information of each control point and the measured value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com