Control method for preventing bending and deformation of head of rough rolling plate blank

A technology of head bending and control method, which is applied in the direction of rolling mill control device, metal rolling, roll speed control, etc., can solve the problems of damage to descaling box, heavy workload of operators, concentration of operators, etc., and achieve improvement The rolling rhythm, the method is simple and reliable, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

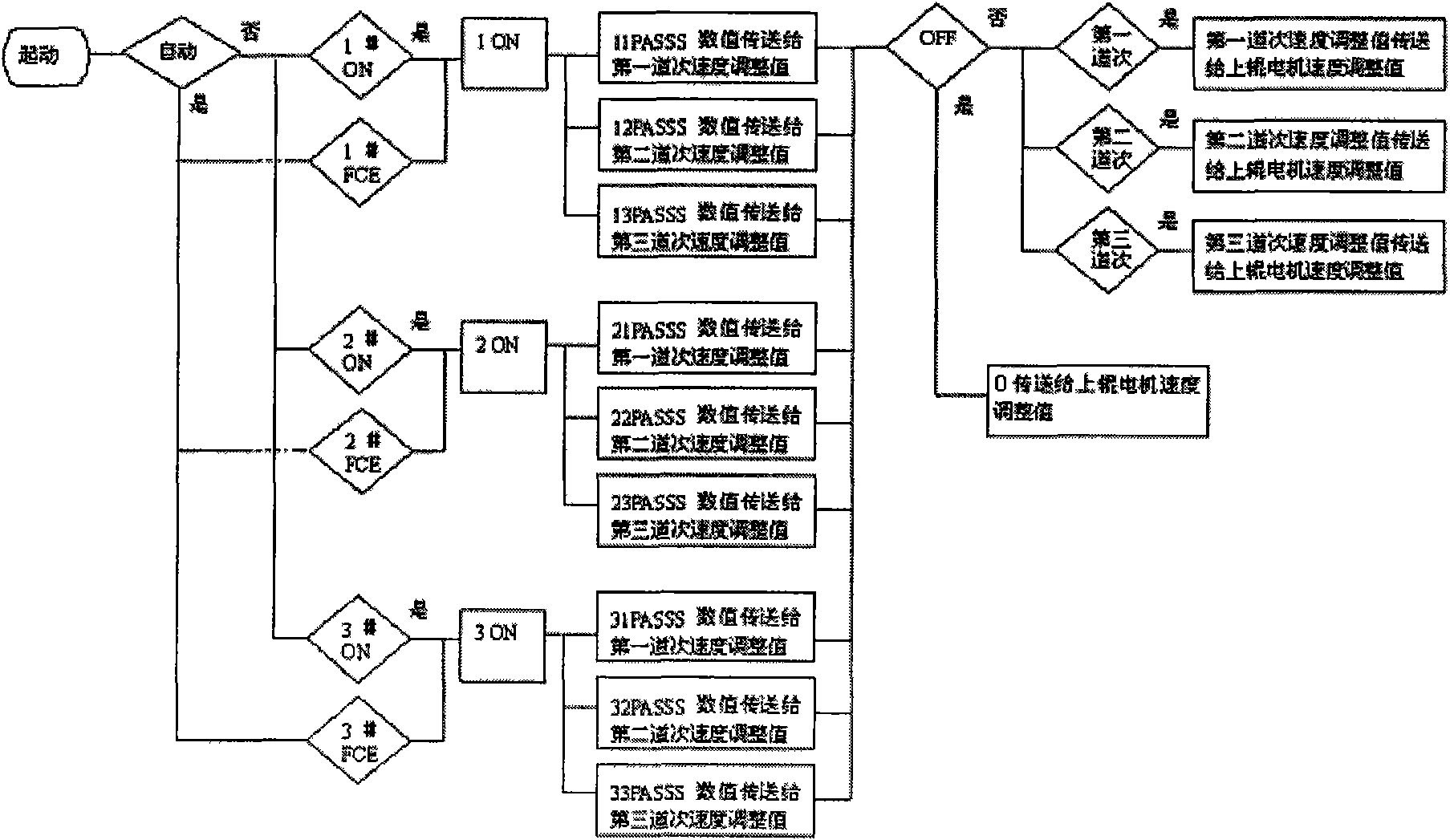

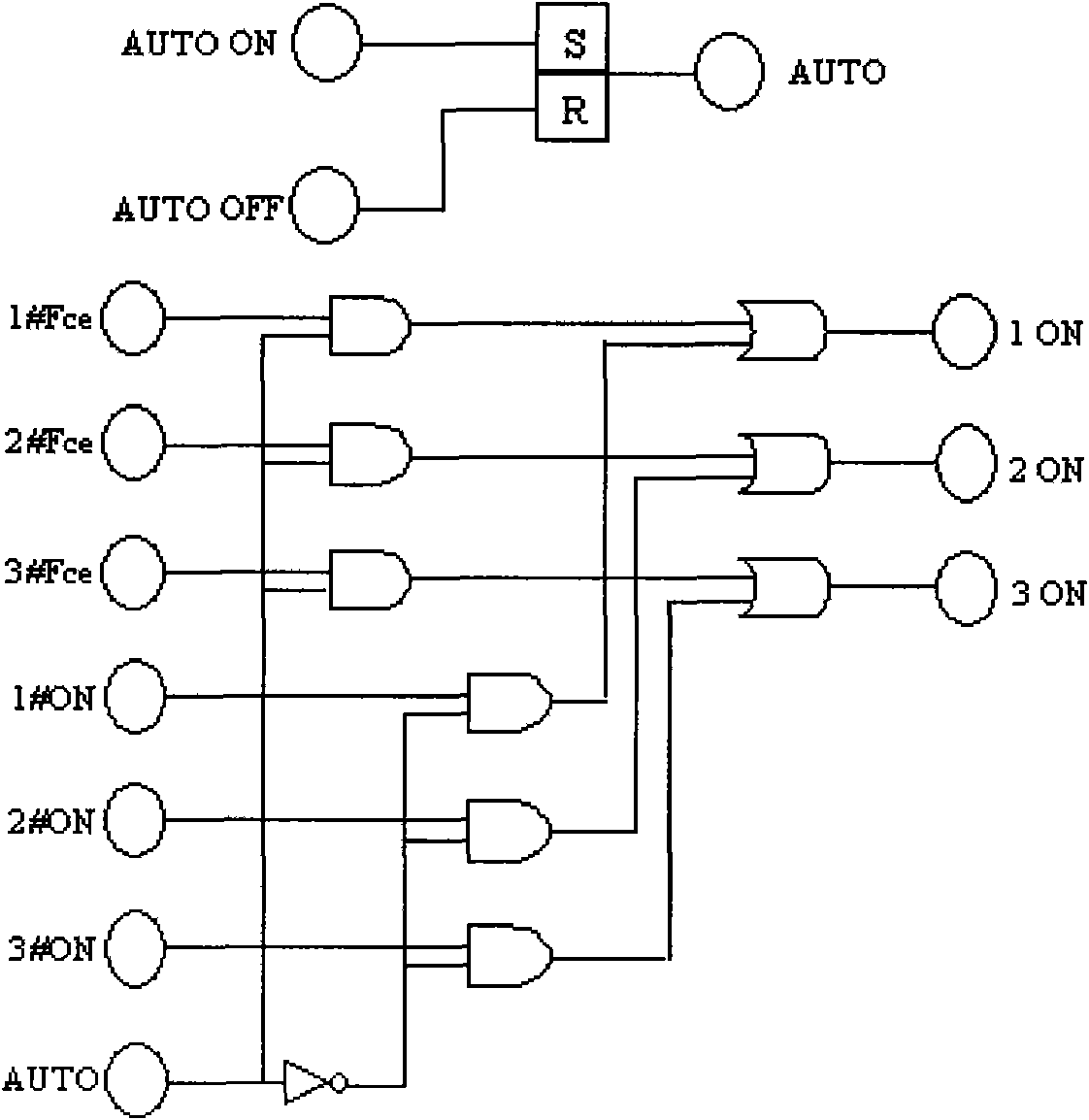

[0017] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0018] The embodiment of the present invention takes a rough rolling mill with three heating furnaces and three rolling passes as an example.

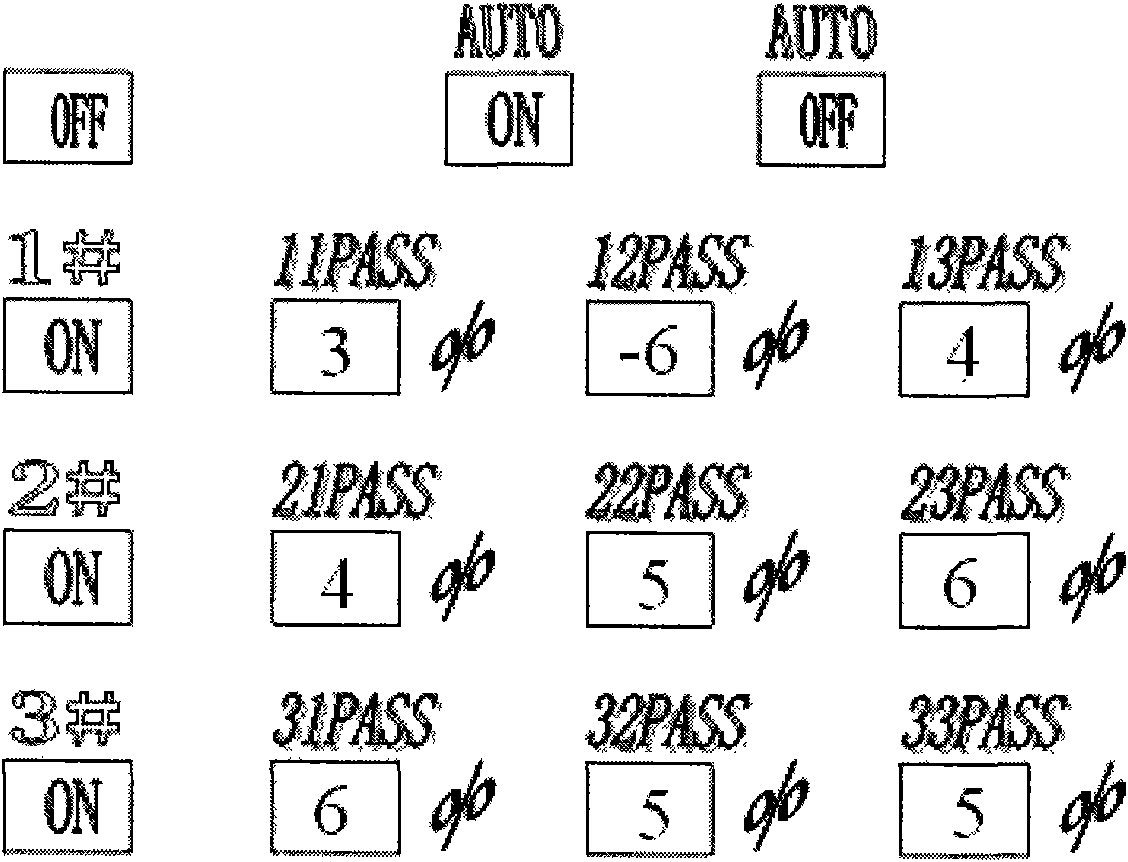

[0019] First, corresponding to different heating furnaces and different steel types, three sets of model adjustment data are preset through the man-machine operation window for three passes. The three sets of model data have a total of nine data frames: "11PASS, 12PASS, 13PASS", "21PASS, 22PASS, 23PASS", "31PASS, 32PASS, 33PASS" (see attached figure 2 ). Among them: the data frames '11PASS', '12PASS', and '13PASS' are the first pass speed balance adjustment value, the second pass speed balance adjustment value, and the third pass speed balance adjustment value of model 1 respectively; the data frame ' 21PASS', '22PASS', and '23PASS' are the first pass speed balance adjustment value, the second pass sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com