Method for preparing polymorphic gold nano-structure by using laser-inducing material through reduction

A gold nanostructure, laser-induced technology, applied in the direction of nanotechnology, can solve the problems of introducing impurities, etc., and achieve the effect of reducing reducibility, simple operation, and no need for chemical reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

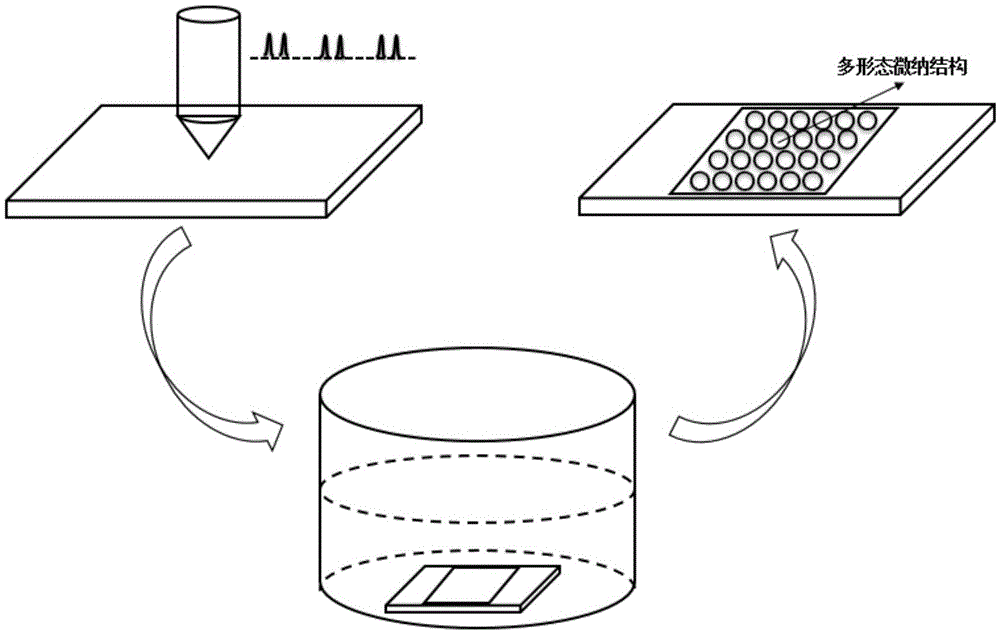

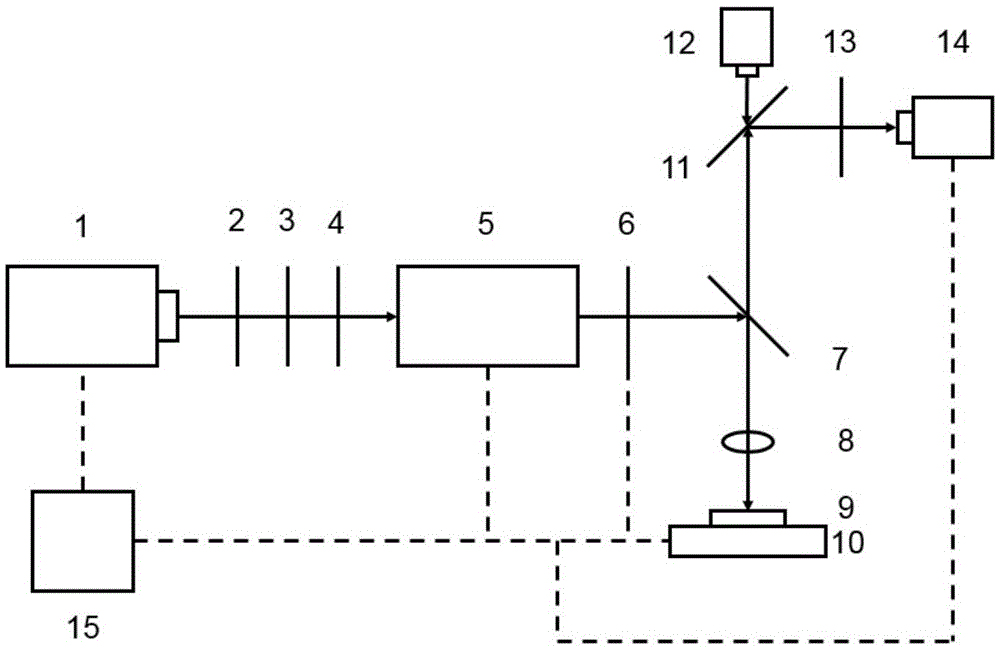

[0025] The method for preparing polymorphic gold nanostructures by using laser-induced reduction of materials, the specific steps are as follows:

[0026] (1) The femtosecond laser generates femtosecond laser, and the pulse form is a single pulse.

[0027] (2) The laser beam enters the femtosecond laser double pulse generator based on the Michelson interferometer, and the femtosecond laser pulse sequence is obtained through time-domain shaping, and the energy ratio of the two sub-pulses is 1:1.

[0028] (3) The femtosecond laser pulse sequence in (2) is focused on the upper surface of the sample to be processed through the focusing objective lens to modify the material. The value aperture of the focusing objective lens used here is 0.15.

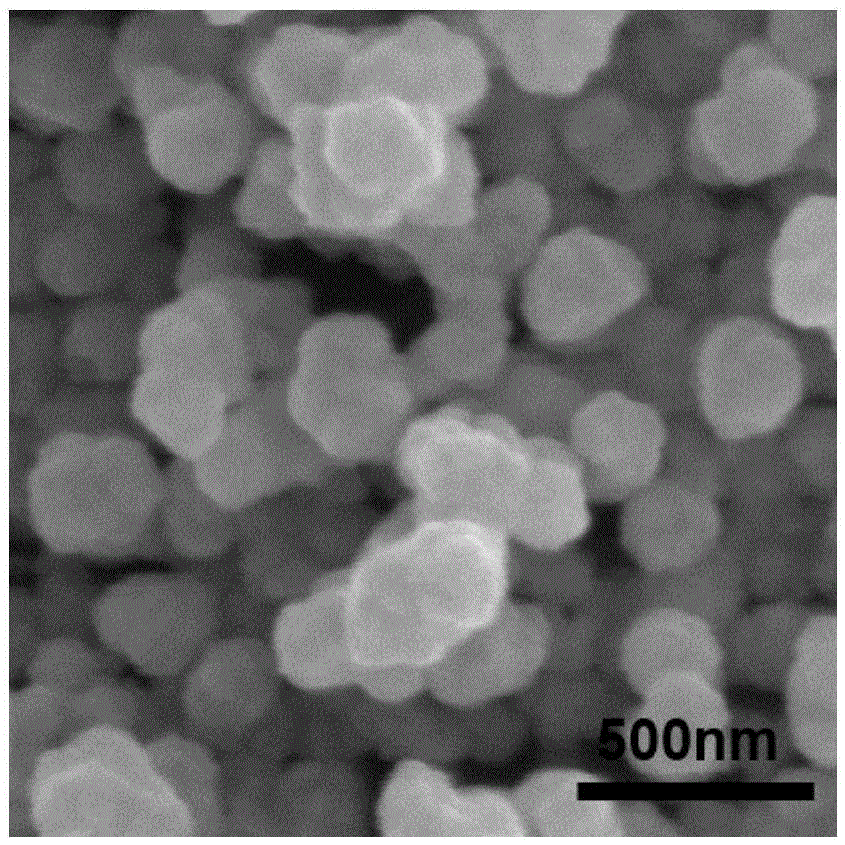

[0029] (4) Adjust the energy of the femtosecond laser to 0.1uJ through the neutral density attenuation plate; use the computer to control the double pulse generator to adjust the pulse delay to 5ps; use the computer to control the movement ...

Embodiment 2

[0033] The method for preparing polymorphic gold nanostructures by using laser-induced reduction of materials, the specific steps are as follows:

[0034] (1) The femtosecond laser generates femtosecond laser, and the pulse form is a single pulse.

[0035] (2) The laser beam enters the femtosecond laser double pulse generator based on the Michelson interferometer, and the femtosecond laser pulse sequence is obtained through time-domain shaping, and the energy ratio of the two sub-pulses is 1:1.

[0036] (3) The femtosecond laser pulse sequence in (2) is focused on the upper surface of the sample to be processed through the focusing objective lens to modify the material. The value aperture of the focusing objective lens used here is 0.15.

[0037] (4) Adjust the energy of the femtosecond laser to 0.1uJ through the neutral density attenuation sheet; use the computer to control the double pulse generator to adjust the pulse delay to 0.5ps; use the computer to control the movemen...

Embodiment 3

[0041] The method for preparing polymorphic gold nanostructures by using laser-induced reduction of materials, the specific steps are as follows:

[0042] (1) The femtosecond laser generates femtosecond laser, and the pulse form is a single pulse.

[0043] (2) The laser beam enters the femtosecond laser double pulse generator based on the Michelson interferometer, and the femtosecond laser pulse sequence is obtained through time-domain shaping, and the energy ratio of the two sub-pulses is 1:1.

[0044] (3) The femtosecond laser pulse sequence in (2) is focused on the upper surface of the sample to be processed through the focusing objective lens to modify the material. The value aperture of the focusing objective lens used here is 0.15.

[0045] (4) Adjust the energy of the femtosecond laser to 0.3uJ through the neutral density attenuator; use the computer to control the double pulse generator to adjust the pulse delay to 0.1ps; use the computer to control the movement of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com