High-capacity silicon-based anode material for lithium ion battery and preparation method thereof, and lithium ion battery

A silicon-based negative electrode material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve problems such as poor long-term cycle performance, silicon volume change, and loss of electrical contact , to achieve the effect of improving cycle performance, increasing electrical conductivity and reducing reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing a silicon-based negative electrode material for a high-capacity lithium-ion battery of the present invention, comprising the following steps:

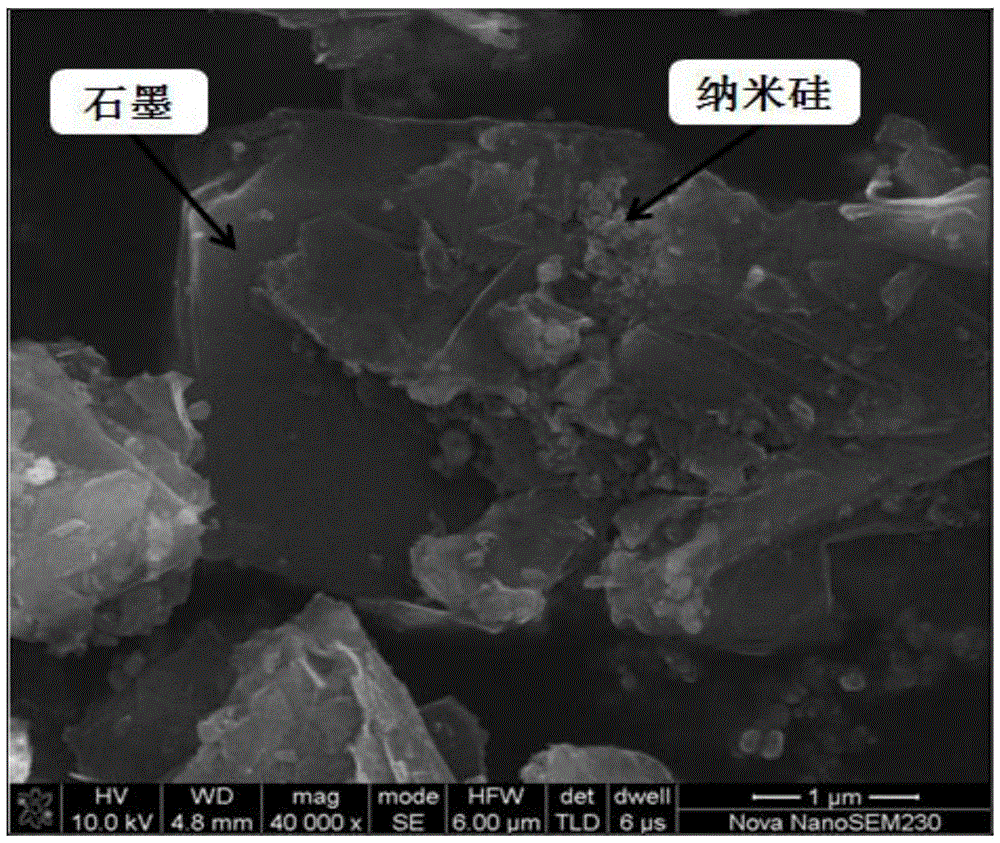

[0034] (1) Add 0.5 g of nano-silicon particles with a particle size of 80 nm into 100 ml of absolute ethanol for ultrasonic dispersion for 60 minutes to obtain a nano-silicon dispersion, and add 5 g of artificial silicon particles with a particle size of 0.6 μm to the dispersion under continuous stirring. Graphite was mixed and stirred for 90 minutes, then 6.1 g of citric acid was added to the dispersion and continued to mix and stir for 60 minutes, and the resulting mixed solution was evaporated to dryness in a water bath and vacuum baked at 60°C for 8 hours to obtain a silicon-carbon composite material precursors;

[0035] (2) roasting the silicon-carbon composite material precursor obtained in step (1) at 450° C. for 3 hours under argon protection, and then grinding to obtain a pyrolytic carbon-coated n...

Embodiment 2

[0040] A method for preparing a silicon-based negative electrode material for a high-capacity lithium-ion battery of the present invention, comprising the following steps:

[0041] (1) Add 0.5 g of nano-silicon particles with a particle size of 8 nm into 200 ml of methanol for ultrasonic dispersion for 120 minutes to obtain a nano-silicon dispersion, and add 2 g of natural graphite with a particle size of 5 μm to the dispersion under continuous stirring. Stir for 120 minutes, then add 3.57g of phenolic resin to the dispersion and continue to mix and stir for 30 minutes. The obtained mixed solution is evaporated to dryness in a water bath and vacuum baked at 120°C for 4 hours to obtain a silicon-carbon composite material precursor;

[0042] (2) Calcining the silicon-carbon composite material precursor obtained in step (1) at 750° C. for 6 hours under argon protection, and then grinding to obtain a pyrolytic carbon-coated nano-silicon / graphite composite material;

[0043] (3) Ge...

Embodiment 3

[0047] A method for preparing a silicon-based negative electrode material for a high-capacity lithium-ion battery of the present invention, comprising the following steps:

[0048] (1) Add 0.5 g of nano-silicon particles with a particle size of 280 nm into 100 ml of N-methylpyrrolidone for ultrasonic dispersion for 40 minutes to obtain a nano-silicon dispersion, and add 10 g of artificial silicon particles with a particle size of 18 μm to the dispersion under continuous stirring. Graphite was mixed and stirred for 30 minutes, then 1.4g of asphalt powder was added to the dispersion and continued to mix and stir for 45 minutes. The resulting mixed solution was evaporated to dryness in a water bath and vacuum baked at 80°C for 12 hours to obtain a silicon-carbon composite material precursor. body;

[0049] (2) Calcining the silicon-carbon composite material precursor obtained in step (1) at 950° C. for 12 hours under argon protection, and then grinding to obtain a pyrolytic carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com