Lithium sulfur battery anode material and lithium sulfur battery utilizing same

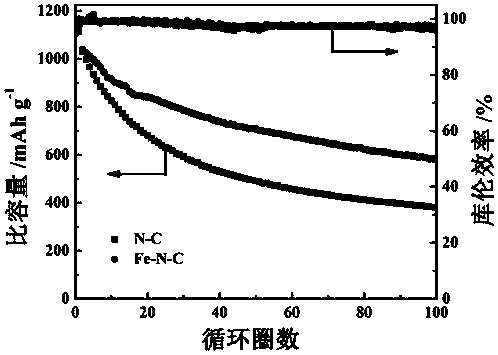

A cathode material, lithium-sulfur battery technology, applied in battery electrodes, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve the problems of restricting the cycle stability of lithium-sulfur batteries, low utilization rate of active materials, loss of active materials, etc., to achieve faster Effects of reaction kinetics, improvement of cycle stability, and improvement of battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) 2g of o-phenylenediamine monomer is ultrasonically dissolved in 2mol / L hydrochloric acid solution, and after the monomer is dissolved, 0.0849g of iron phthalocyanine is added under ultrasonic conditions, and then 5g of nano-silica spherical hard template is ultrasonically Under conditions, add to the above solution, add 20mL of 1mol / L FeCl 3 Aqueous solution, stirred and polymerized at 0°C for 24h.

[0031] (2) The reactants obtained above were centrifuged and dried to obtain a solid product. Under a nitrogen atmosphere, the temperature was raised to 900° C. at a rate of 10° C. / min, kept at this temperature for 1 hour, and taken out after naturally cooling down to room temperature.

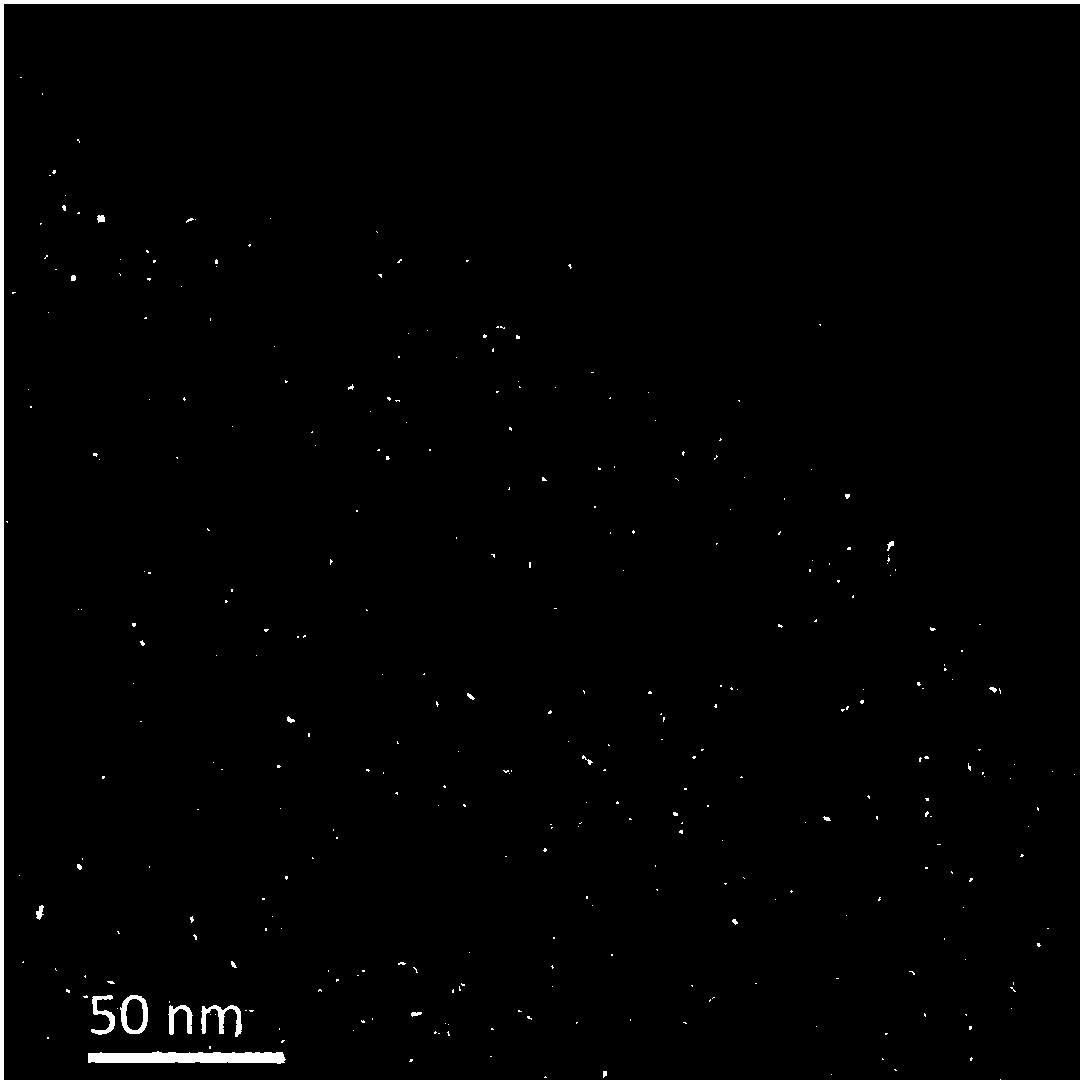

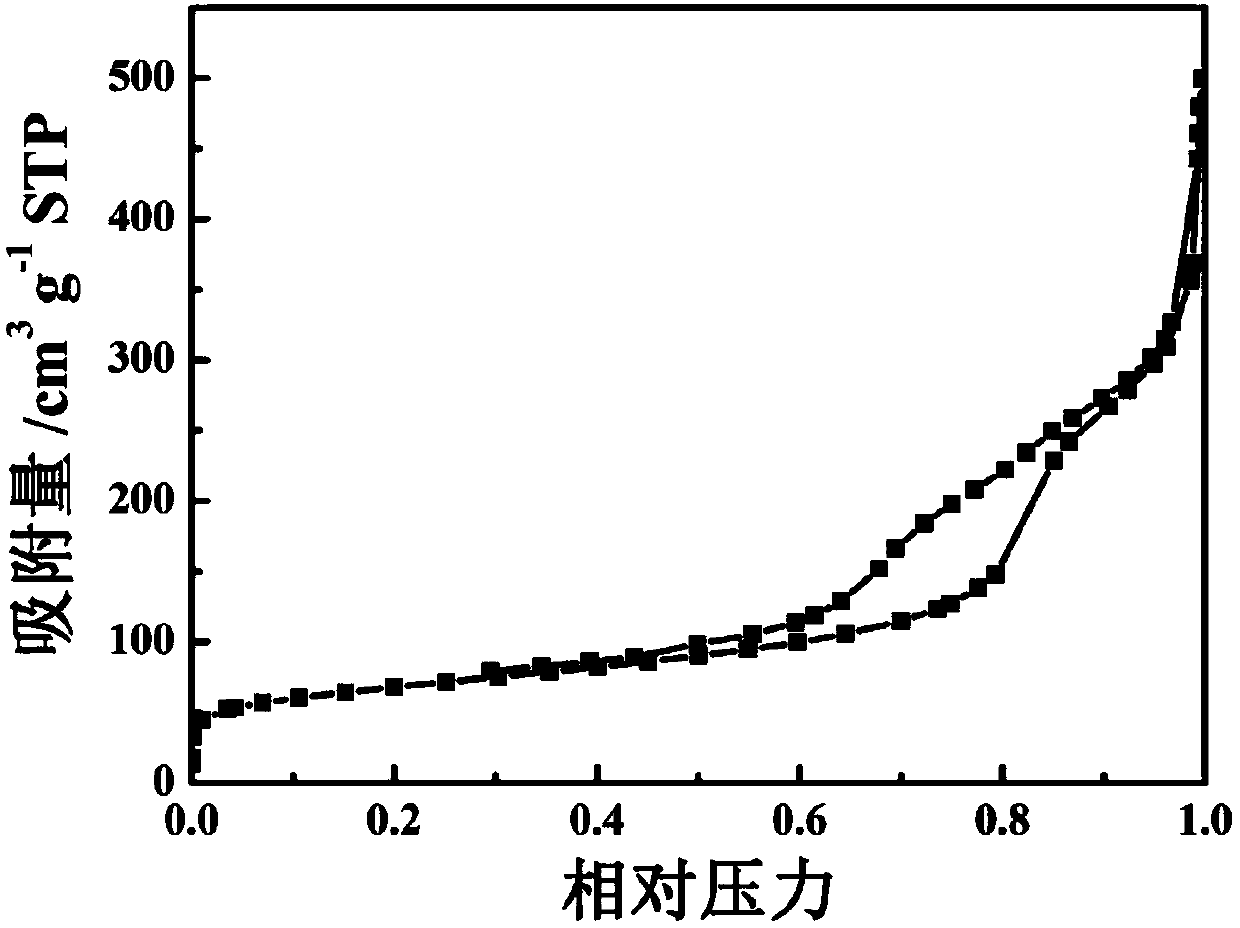

[0032] (3) After the solid is ground into powder, it is added to 4 mol / L ammonium bifluoride aqueous solution to etch away the nano-silicon spheres, stirred and etched at room temperature for 24 hours, cleaned with deionized water, and dried at 60°C for 24 hours to obtain Fe-N heteroat...

Embodiment 2

[0036] (1) 2g of o-phenylenediamine monomer is ultrasonically dissolved in 2mol / L hydrochloric acid solution, and after the monomer is dissolved, 0.1773g of iron phthalocyanine is added under ultrasonic conditions, and then 5g of nano-silica spherical hard template is ultrasonically Under certain conditions, it was added to the above solution, and after ultrasonication for 0.5h, 20mL of 1mol / L ammonium persulfate aqueous solution was added, and the mixture was stirred and polymerized at 0°C for 24h.

[0037] (2) The reactants obtained above were centrifuged and dried to obtain a solid product. Under a nitrogen atmosphere, the temperature was raised to 900° C. at a rate of 5° C. / min, kept at this temperature for 2 hours, and taken out after naturally cooling down to room temperature.

[0038] (3) After the solid is ground into powder, it is added to 4 mol / L ammonium bifluoride aqueous solution to etch away the nano-silicon spheres, stirred and etched at room temperature for 24 h...

Embodiment 3

[0042] (1) 2g of o-phenylenediamine monomer is ultrasonically dissolved in 2mol / L hydrochloric acid solution, and after the monomer is dissolved, 0.1773g of iron phthalocyanine is added under ultrasonic conditions, and then 5g of nano-silica spherical hard template is ultrasonically Under the conditions, add to the above solution, add 40mL 1mol / L FeCl 3 Aqueous solution, stirred and polymerized at 0°C for 24h.

[0043] (2) The reactants obtained above were centrifuged and dried to obtain a solid product. Under a nitrogen atmosphere, the temperature was raised to 900° C. at a rate of 5° C. / min, kept at this temperature for 1 hour, and taken out after naturally cooling down to room temperature.

[0044] (3) After the solid is ground into powder, it is added to 4 mol / L ammonium bifluoride aqueous solution to etch away the nano-silicon spheres, stirred and etched at room temperature for 24 hours, cleaned with deionized water, and dried at 60°C for 24 hours to obtain Fe-N heteroat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com