Functionalized diaphragm for lithium-sulfur battery and preparation method of functionalized diaphragm

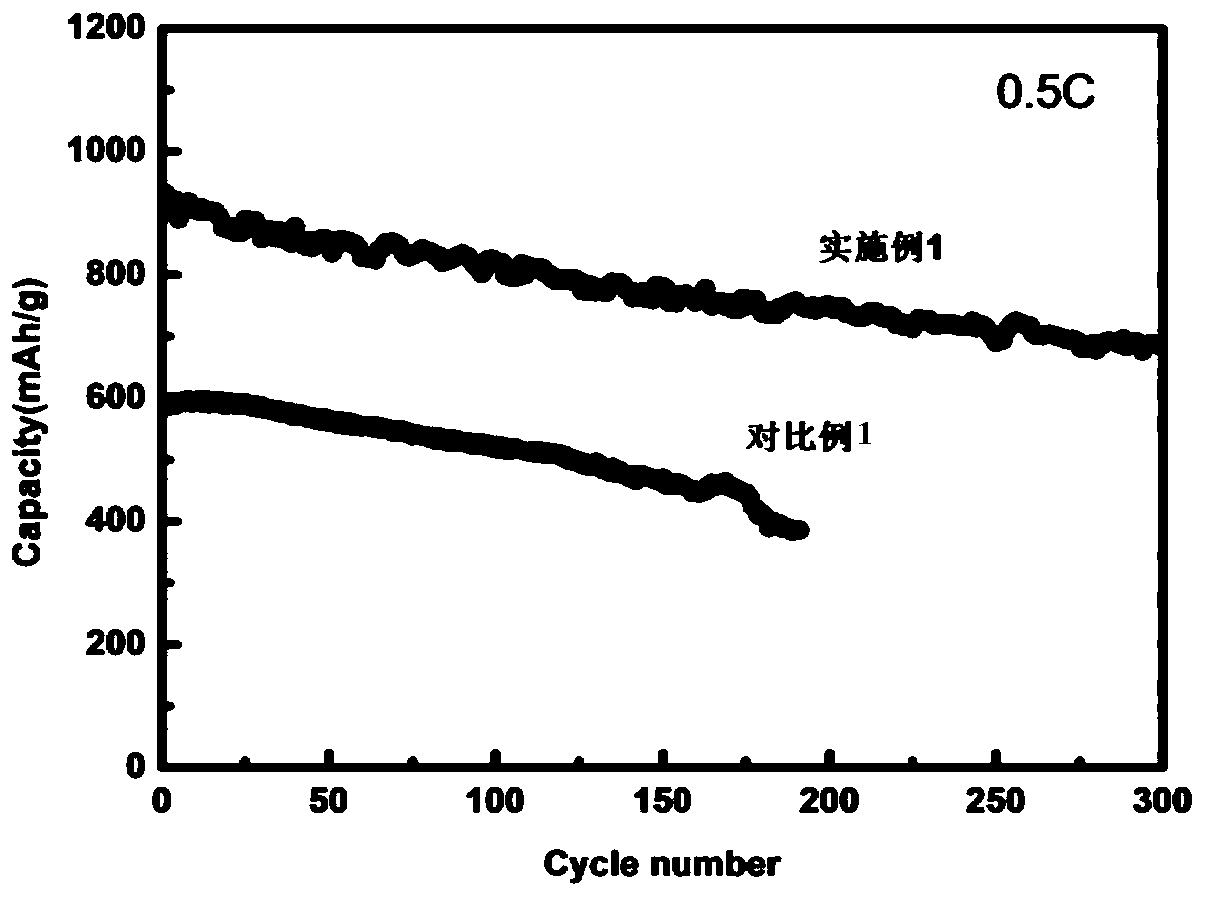

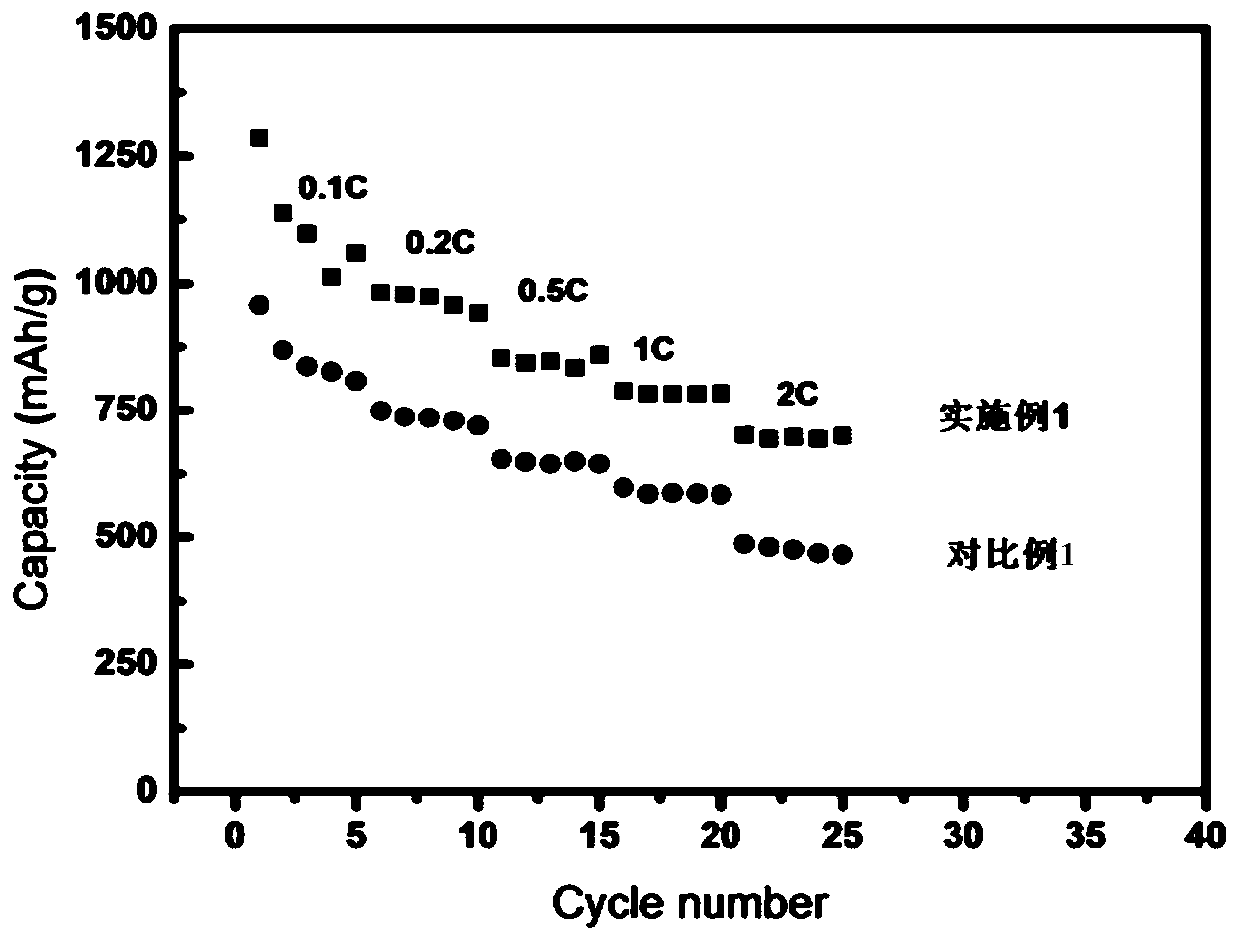

A lithium-sulfur battery and functionalized technology, applied in the field of electrochemistry, can solve the problems of difficulty in inhibiting the diffusion of polysulfides, poor cycle stability of lithium-sulfur batteries, loss of active material sulfur, etc. Chemical properties, the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A functionalized separator for lithium-sulfur batteries, comprising a base film, one side of the base film is provided with a conductive adsorption coating; the conductive adsorption coating includes a conductive powder carbon material and an adsorption inorganic polar material; The adsorbed inorganic polar material is obtained from the precursor after heat treatment.

[0031] The base film is Celgard commercial polypropylene (PP) membrane; the thickness of the base film is 25 μm. The conductive powder carbon material is Super P; the particle size of the adsorbed inorganic polar material is 0.15-3 μm.

[0032] The preparation method of the precursor includes the following steps: weighing 100 g of ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) After stirring and dissolving in 250ml of deionized water, continue to add 25g of glucose, mechanically stirring to dissolve, and control the spray air inlet temperature to discharge at 160℃ to obtain FeSO through a spray dryer. 4 / Gluco...

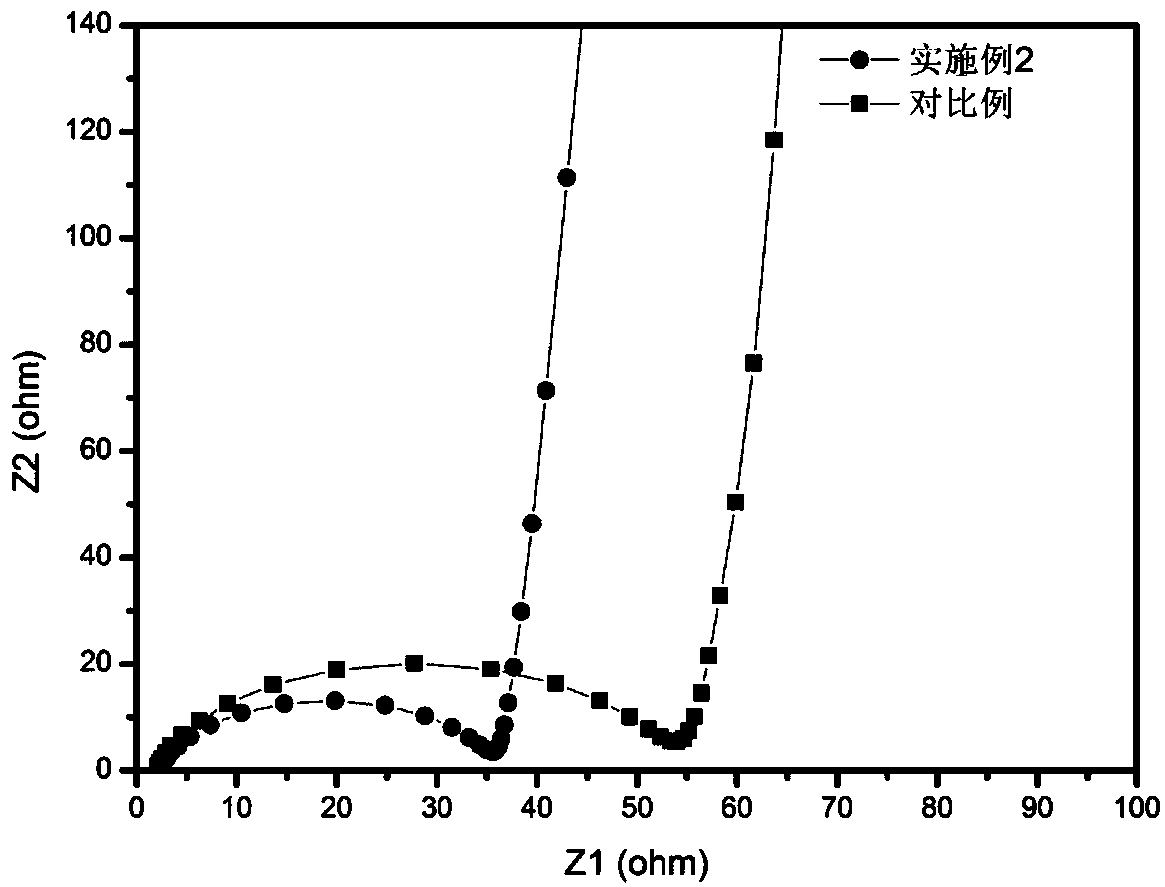

Embodiment 2

[0037] A functionalized separator for lithium-sulfur batteries, comprising a base film, one side of the base film is provided with a conductive adsorption coating; the conductive adsorption coating includes a conductive powder carbon material and an adsorption inorganic polar material; The adsorbed inorganic polar material is obtained from the precursor after heat treatment.

[0038] The base film is Celgard commercial polypropylene (PP) membrane; the thickness of the base film is 25 μm. The conductive powder carbon material is Super P; the particle size of the adsorbed inorganic polar material is 0.10-5 μm.

[0039] The preparation method of the precursor includes the following steps: weigh 100g of nickel sulfate, stir and dissolve in 250ml of deionized water, continue to add 25g of sucrose, mechanically stir to dissolve, and control the spray inlet temperature at 160°C through a spray dryer. NiSO produced by discharge 4 / Sucrose precursor.

[0040] The preparation method of the f...

Embodiment 3

[0044] A functionalized separator for lithium-sulfur batteries, comprising a base film, one side of the base film is provided with a conductive adsorption coating; the conductive adsorption coating includes a conductive powder carbon material and an adsorption inorganic polar material; The adsorbed inorganic polar material is obtained from the precursor after heat treatment.

[0045] The base film is a Celgard commercial PP / PE / PP three-layer composite membrane; the thickness of the base film is 25 μm. The conductive powder carbon material is Super P; the particle size of the adsorbed inorganic polar material is 0.2-3 μm.

[0046] The preparation method of the precursor includes the following steps: weigh 100g of ferric nitrate and stir and dissolve it in 250ml of deionized water, continue to add 30g of melamine, mechanically stir and dissolve, and control the spray inlet temperature at 160°C through a spray dryer. Fe(NO 3 ) 3 / Melamine precursor.

[0047] The preparation method of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com