Multifunctional diaphragm of lithium-sulfur battery and preparation method of multifunctional diaphragm

A lithium-sulfur battery, multi-functional technology, applied in lithium batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve the problem of limited modification ability of separators, poor performance of lithium-sulfur batteries, and uniform dispersion of polydopamine and carbon materials And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

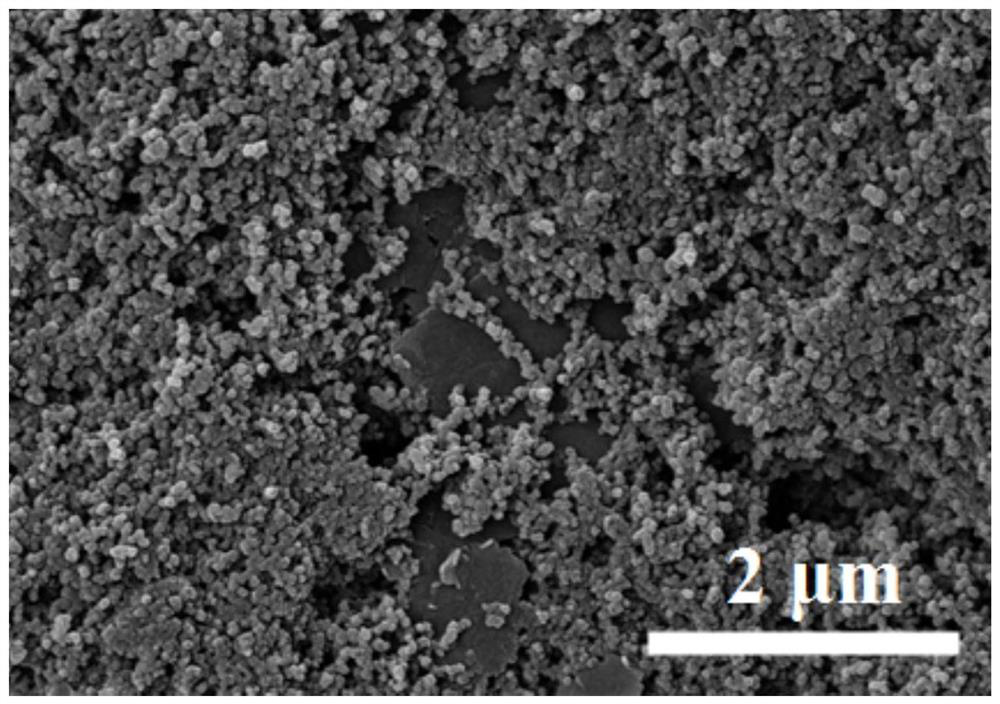

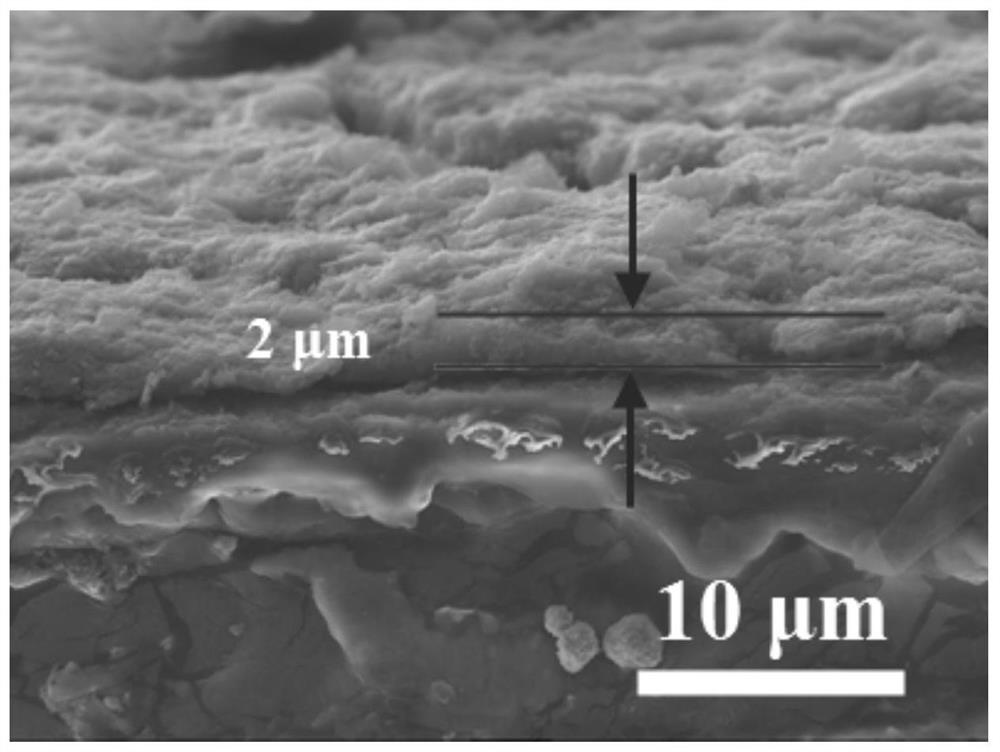

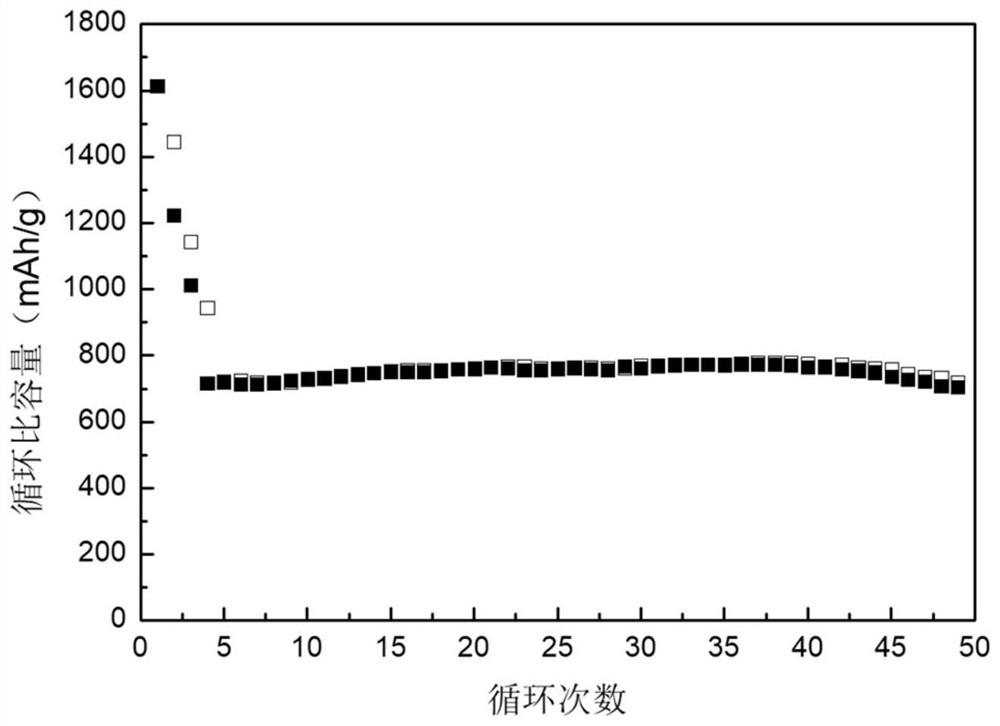

[0048] A lithium-sulfur battery multifunctional diaphragm of the present invention, comprising a diaphragm substrate polyethylene porous membrane, the two surfaces of the diaphragm substrate are coated with a modified coating, and the modified coating is polydopamine, nitrogen-doped graphene and titanium carbide Composite coating, the content ratio of polydopamine, nitrogen-doped graphene and titanium carbide in the modified coating is about 1:0.15:0.15, and the thickness of the coating is 2 μm.

[0049] The preparation method of the multifunctional membrane of the present embodiment comprises the following steps:

[0050] (1) Mix ammonia water, nitrogen-doped graphene, sodium diisooctyl sulfonate, isopropanol, and deionized water in a mass ratio of 1:0.01:16.25:20:230 to obtain solution A;

[0051] Mix dopamine hydrochloride and deionized water evenly at a mass ratio of 1:20 to obtain solution B;

[0052] (2) Under stirring conditions, according to the mass ratio of solution...

Embodiment 2

[0058] A lithium-sulfur battery multifunctional diaphragm of the present invention, comprising a diaphragm substrate polyimide porous membrane, the two surfaces of the diaphragm substrate are coated with a modified coating, the modified coating is carbon nanotubes containing polydopamine and oxygen doped and molybdenum sulfide composite coating, the content ratio of polydopamine, oxygen-doped carbon nanotubes and molybdenum sulfide in the modified coating is about 1:0.20:0.20, and the thickness of the coating is 20 μm.

[0059] The preparation method of the multifunctional membrane of the present embodiment comprises the following steps:

[0060] (1) Mix ammonia water, oxygen-doped carbon nanotubes, Ketjen black, sodium dioctyl sulfonate, methanol, and deionized water at a mass ratio of 1:10:23:0.325:95:150 Evenly, solution A is obtained;

[0061] Mix dopamine hydrochloride and deionized water uniformly at a mass ratio of 1:1 to obtain solution B;

[0062] (2) According to t...

Embodiment 3

[0068] A lithium-sulfur battery multifunctional diaphragm of the present invention, comprising a diaphragm substrate polyvinylidene fluoride porous membrane, the two surfaces of the diaphragm substrate are coated with a modified coating, the modified coating contains polydopamine, fullerene and di For the composite coating of vanadium, the mass ratio of polydopamine, fullerene and vanadium pentoxide in the modified coating is about 1:0.01:0.20, and the thickness of the coating is 10 μm.

[0069] The preparation method of the multifunctional membrane of the present embodiment comprises the following steps:

[0070] (1) Mix ammonia water, fullerene, polyoxyethylene polyoxypropylene pentaerythritol ether, ethanol, isopropanol, and deionized water in a mass ratio of 1:65:13.5:30:20:45 to obtain a solution A;

[0071] Mix dopamine hydrochloride and deionized water uniformly at a mass ratio of 1:50 to obtain solution B;

[0072] (2) Under stirring conditions, slowly add solution B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com