High-dispersion iron catalyst by direct coal hydrogenation liquefaction

A hydrogenation liquefaction and catalyst technology is applied in the field of highly dispersed iron-based catalyst products and high-dispersion iron-based catalysts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The catalyst listed in this example is a coal direct liquefaction catalyst sample obtained by using a Chinese bituminous coal as the carrier of the catalyst and using ferrous sulfate as the main raw material. Concrete steps are: get 5.7 kilograms of ferrous sulfate heptahydrate, add 46.88 kilograms of tap water to dissolve, then join in 15.78 kilograms of coal dust, stir to obtain ferrous sulfate coal slurry, get 2.55kg ammoniacal liquor and join in 34.77 kilograms of tap waters in addition. Under stirring, add 2 / 5 of the above-mentioned amount of ammonia water into the above-mentioned ferrous sulfate coal slurry, and continue stirring for 10 seconds after adding. The above reaction product was placed at 40°C in 3m 3 Oxidation under the air flow rate of / h, after the oxidation reaction is completed, centrifugal filtration is carried out, and the obtained filter cake is the catalyst of the present invention. The appearance of the catalyst is black particles, see attache...

Embodiment 2

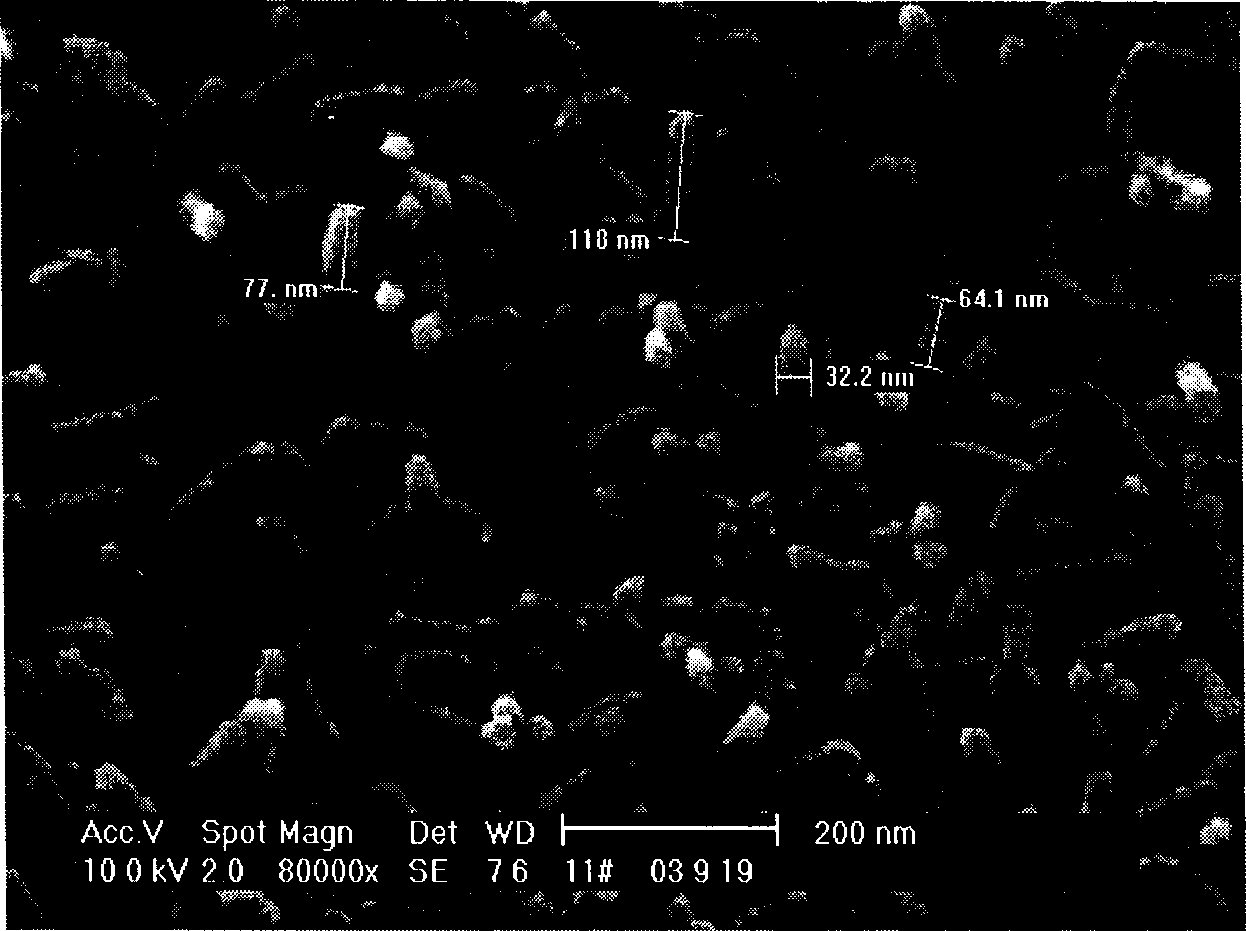

[0025] The catalyst listed in this example is a kind of Chinese bituminous coal as the carrier for the preparation of the catalyst and a ferrous iron salt as the main raw material to obtain a highly dispersed and disposable iron-based catalyst for direct coal hydrogenation to liquefaction. The appearance of this catalyst sample is also black powdery fine particles, see attached image 3 . under a scanning electron microscope at 80,000 magnification image 3 The observation of the morphological characteristics of the catalyst samples shown shows that the size of most of the catalyst active components is about 100nm in length and 40nm in width, see attached Figure 4 . Analysis of the catalyst also showed that the catalyst sample had a Fe content of 7 wt%, a dry coal content of 89 wt%, and a moisture content of 4 wt%.

[0026]

Embodiment 3

[0028] The catalyst samples listed in this example use a kind of Chinese lignite as the carrier for the preparation of the catalyst, and use ferrous iron salt as the main raw material to obtain a highly dispersed and disposable iron-based catalyst for direct hydrogenation liquefaction of coal. The appearance of the catalyst is dark brown powdery fine particles, see attached Figure 5 . attached Figure 6 is true Figure 5 The photo of the morphology of the catalyst shown is observed under a scanning electron microscope at a power of 40,000. The results show that the size of most active components of the catalyst is about 100nm in length and about 40nm in width. Analysis of the catalyst product also showed an Fe content of 5 wt%, a dry coal content of 60 wt%, and a moisture content of 35 wt%.

[0029]

[0030] The above three examples all show that compared with the finely ground pyrite catalyst, the catalyst of the present invention has the characteristics of less...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com