Ball-milling assisted method for preparing carbon nitrogen based monatomic iron catalyst

An iron catalyst, carbon-nitrogen-based single technology, applied in electrical components, grain processing, battery electrodes, etc., can solve the problems of easy agglomeration of metal active sites, cumbersome catalyst preparation process, unfavorable sustainable development, etc., and achieve low cost. , short response time, environmental friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 81 milligrams (mg) of zinc oxide, 289 mg of 2-ethylimidazole, 10 mg of ammonium sulfate, and 16 mg of iron porphyrin into an 80 mL ball mill jar, mix well, then add 200 μL of N,N-diethylformamide, and mix 20 Put the zirconia balls with a diameter of 10mm into the ball milling pot, install the ball milling pot on the ball mill, adjust the ball milling condition to 50 Hz, and ball mill twice, each time for 30 minutes, with a stop of 5 minutes in between. After the ball milling, wash the samples in the ball mill tank with water, centrifuge and wash twice with ethanol, dry in a vacuum oven at 80°C for 12 hours, and put the powder into a magnetic boat after simple grinding, and heat it in a tube furnace. Nitrogen or argon protection is required, the heating temperature is 950°C, the heating rate is 5°C / min, the pyrolysis is 3h, and the black Fe-N-C single-atom catalyst is obtained.

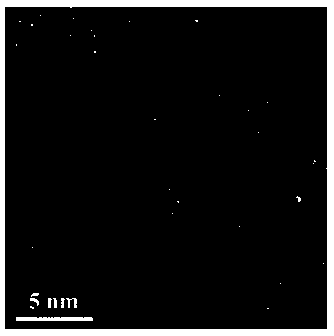

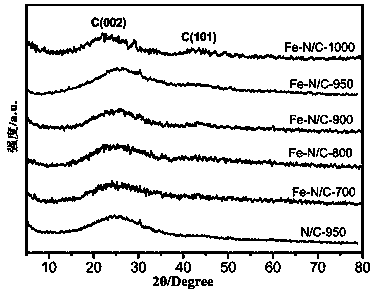

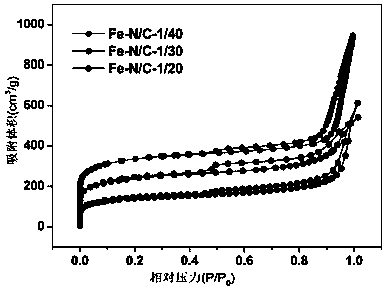

[0031] The Fe-N-C single-atom catalyst, high-angle annular dark field image-scanning tra...

Embodiment 2

[0036] Add 81 milligrams (mg) of zinc oxide, 289 mg of 2-ethylimidazole, 10 mg of ammonium sulfate, and 21 mg of iron porphyrin into an 80 mL ball mill jar, mix well, then add 200 μL of N,N-diethylformamide, and mix 20 Put the zirconia balls with a diameter of 10mm into the ball milling pot, install the ball milling pot on the ball mill, adjust the ball milling condition to 50 Hz, and ball mill twice, each time for 30 minutes, with a stop of 5 minutes in between. After the ball milling, wash the samples in the ball mill tank with water, centrifuge and wash twice with ethanol, dry in a vacuum oven at 80°C for 12 hours, and put the powder into a magnetic boat after simple grinding, and heat it in a tube furnace. Nitrogen or argon protection is required, the heating temperature is 950°C, the heating rate is 5°C / min, the pyrolysis is 3h, and the black Fe-N-C single-atom catalyst is obtained.

Embodiment 3

[0038] Add 81 milligrams (mg) of zinc oxide, 289 mg of 2-ethylimidazole, 10 mg of ammonium sulfate, and 31 mg of iron porphyrin into an 80 mL ball mill jar, mix well, then add 200 μL of N,N-diethylformamide, and mix 20 Put the zirconia balls with a diameter of 10mm into the ball milling pot, install the ball milling pot on the ball mill, adjust the ball milling condition to 50 Hz, and ball mill twice, each time for 30 minutes, with a stop of 5 minutes in between. After the ball milling, wash the samples in the ball mill tank with water, centrifuge and wash twice with ethanol, dry in a vacuum oven at 80°C for 12 hours, and put the powder into a magnetic boat after simple grinding, and heat it in a tube furnace. Nitrogen or argon protection is required, the heating temperature is 950°C, the heating rate is 5°C / min, the pyrolysis is 3h, and the black Fe-N-C single-atom catalyst is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com