Preparation method and device of 1-cyano-2-propenyl acetate

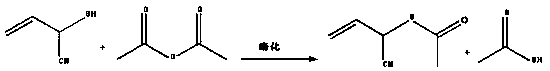

A technology of acryl acetate and cyano group, which is applied in the field of preparation of 1-cyano-2-propenyl acetate, can solve the problems of high cost, many side reactions, high toxicity, etc., and achieve improved reaction efficiency, Guaranteed timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

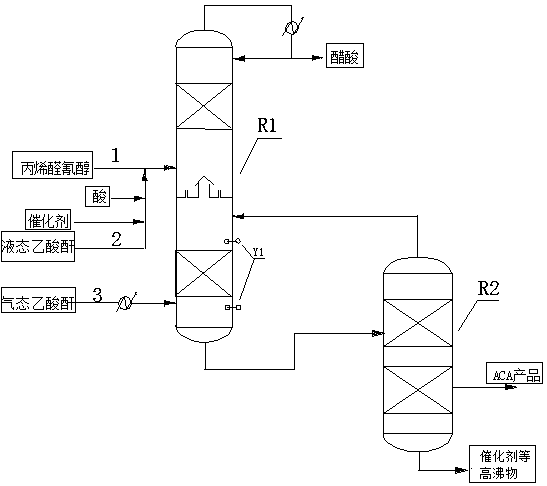

[0057] According to attached figure 1 The flow diagram shown carries out the procedure for the preparation of 1-cyano-2-propenyl acetate. in:

[0058] The esterification reaction tower R1 is a packed reaction tower with a diameter of 0.2m and a height of 2.0m; the distillation tower R2 is a distillation tower with a diameter of 0.1m and a height of 1.0m.

[0059] 1) Esterification reaction of acrolein cyanohydrin

[0060] Acrolein cyanohydrin is sent into the first pipeline 1 at 85.6g / min, the catalyst DMAP formate is mixed with liquid acetic anhydride at 79.5g / min in the second pipeline 2 at 0.36g / min, and phosphoric acid is mixed at 0.45 g / min is added to the second pipeline 2, the second pipeline 2 is communicated with the first pipeline 1, and the time from the phosphoric acid feeding point to the esterification reaction tower R1 is 6min, the catalyst DMAP formate, liquid acetic anhydride, phosphoric acid, The four components of acrolein cyanohydrin are fed into the fee...

Embodiment 2

[0070] According to attached figure 1 The flow diagram shown carries out the continuous preparation of 1-cyano-2-propenyl acetate. in:

[0071] The esterification reaction tower R1 is a multistage stirring reaction tower with a diameter of 0.2m and a height of 2.0m.

[0072] The distillation tower R2 is a distillation tower with a diameter of 0.1 m and a height of 1.0 m.

[0073] 1) Esterification reaction of acrolein cyanohydrin

[0074] Acrolein cyanohydrin is sent into the first pipeline 1 at 78.5g / min, catalyst DMAP acetate is mixed with liquid acetic anhydride at 76.5g / min in the second pipeline 2 at 0.85g / min, and sulfuric acid is mixed at 0.95 g / min is added to the second pipeline 2, the second pipeline 2 is connected with the first pipeline 1, the time from the sulfuric acid feeding point to the esterification reaction tower R1 is 5min, and the four components are added through the first pipeline 1. To the feed inlet of the esterification reaction tower R1, feed in...

Embodiment 3

[0083] According to attached figure 1 The flow diagram shown carries out the continuous preparation of 1-cyano-2-propenyl acetate. in:

[0084] The esterification reaction tower R1 is a multistage stirring reaction tower with a diameter of 0.2m and a height of 2.0m.

[0085] The distillation tower R2 is a distillation tower with a diameter of 0.1 m and a height of 1.0 m.

[0086] 1) Esterification reaction of acrolein cyanohydrin

[0087] Acrolein cyanohydrin is sent into the first pipeline 1 at 95.6g / min, catalyst DMAP butyrate is mixed with liquid acetic anhydride at 55.6g / min in the second pipeline 2 at 2.25g / min, and phosphoric acid is mixed at 0.09 g / min is added to the second pipeline 2, the first pipeline 1 is connected to the second pipeline 2, the time from the phosphoric acid feeding point to the reaction tower is 6min, and the four components are added to the esterification through the first pipeline 1 Feed inlet of reaction tower R1, feed in the tower, feed tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com