Low-loss black hole micro-etching liquid as well as preparation method and application thereof

A technology of micro-etching liquid and black hole is applied in the field of low-loss black-hole micro-etching liquid and its preparation, which can solve the problems of easy re-adsorption of black hole conductive materials on the copper surface, difficulty in meeting process requirements, and large loss of copper surface. , to achieve excellent stripping effect, ensure surface performance and yield, and reduce copper surface loss.

Pending Publication Date: 2022-06-03

上海富柏化工有限公司 +2

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

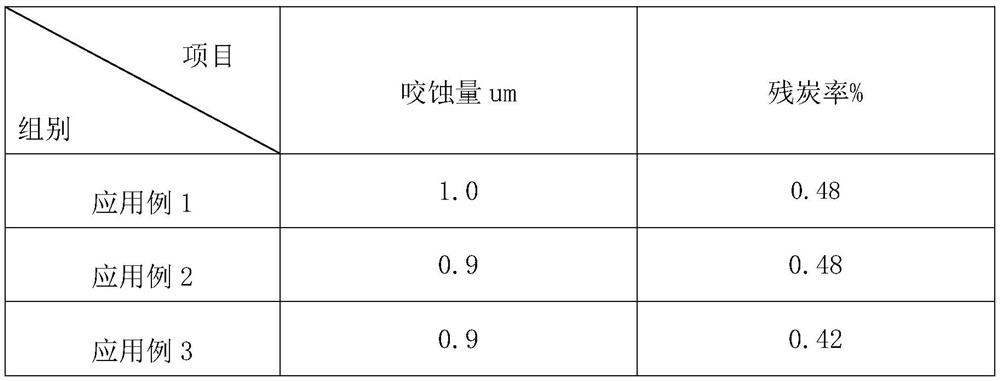

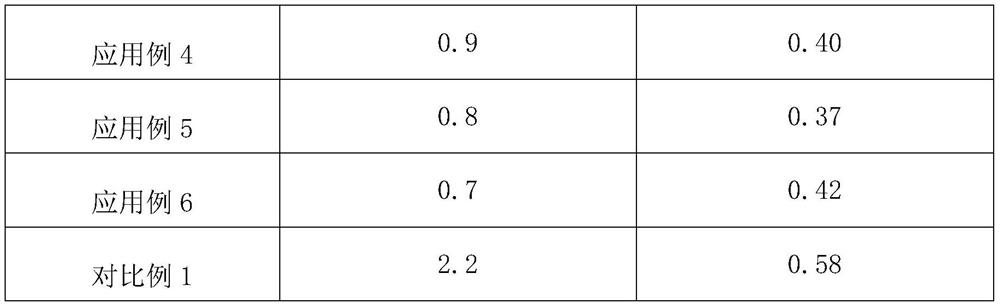

[0004] Although the above-mentioned sulfuric acid-hydrogen peroxide system can also complete the micro-etching treatment of black holes, its application is often limited. The main reason is that it requires an etching amount of more than 2um to peel off the black hole conductive material, and the loss of copper surface after peeling is generally relatively small. Large, the stripped black hole conductive material is also very easy to re-adsorb on the copper surface, so it is difficult to meet the process requirements, and the commercial value is low

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2-6

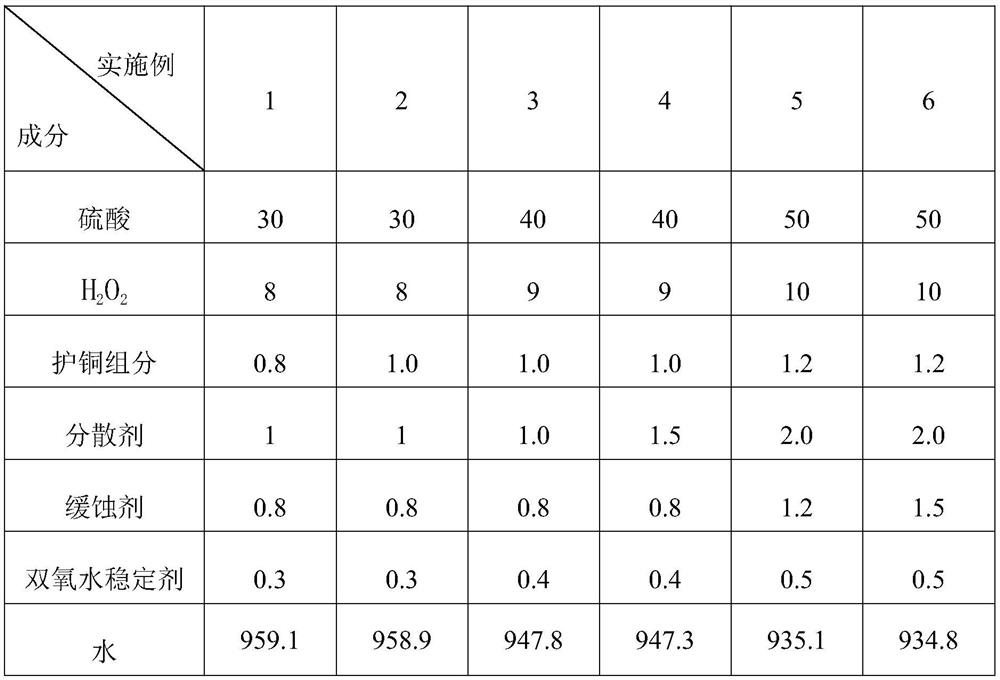

[0028] The components and their weights (g) of the low-loss black hole micro-etching solution in Table 1 Examples 1-6

Embodiment 7

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| carbon residual rate | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

| carbon residual rate | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to the technical field of printed circuit board processing, in particular to a low-loss black hole micro-etching solution and a preparation method and application thereof. The low-loss black hole micro-etching liquid is prepared from the following components in percentage by weight: 30 to 50 permillage of sulfuric acid, 8 to 1 permillage of H2O2, 0.8 to 1.2 permillage of a copper protecting component, 1.0 to 2.0 permillage of a dispersing agent, 0.8 to 1.5 permillage of a corrosion inhibitor, 0.3 to 1.0 permillage of a hydrogen peroxide stabilizer and the balance of water, and the copper protection component is one or more of dodecenylsuccinic acid, monoethanolamine borate and triethanolamine borate. According to the low-loss black hole micro-etching liquid with the proportion, the copper surface black hole conductive material is effectively stripped, meanwhile, the loss of the copper surface is reduced, the stripped black hole conductive material is not prone to being reversely adhered to the copper surface, and therefore the surface performance and the yield of a PCB are guaranteed.

Description

technical field [0001] The present application relates to the technical field of printed circuit board processing, and more particularly, to a low-loss black hole micro-etching solution and a preparation method and application thereof. Background technique [0002] Black hole technology refers to the technology of depositing a layer of black high-quality conductive nano-carbon on the hole wall, and using the excellent conductivity of this layer of medium for subsequent electroplating operations. It is also a key process in circuit board production. It is not only adsorbed on the fibers in the hole, but also adsorbed on the metal copper surface. If the black hole liquid on the surface is allowed to exist on the surface, it will affect the bonding force of electroplating. Therefore, the black hole micro-etching treatment technology came into being. [0003] The black hole micro-etching treatment technology in the related art mainly includes a sodium persulfate (SPS) system, a ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23F1/18

CPCC23F1/18Y02P10/20

Inventor 夏金良饶猛

Owner 上海富柏化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com