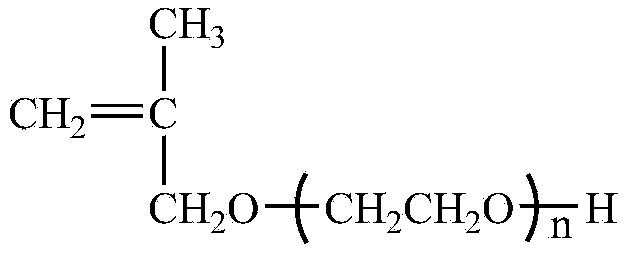

Method for preparing polycarboxylate superplasticizer by combination of polyether macromonomers of two structures

A polyether macromonomer and macromonomer technology, which is applied in the field of polymer compound preparation, can solve problems such as difficult to meet actual needs, and achieve moderate molecular weight, improved comprehensive performance, and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The method for preparing a polycarboxylate water reducer by combining polyether macromonomers with two structures is to add 11.0g of macromonomer A, 17.1g of macromonomer C and 55g of water into a flask at 50°C, and place the flask Put it into the oil bath of a magnetic stirrer, heat and stir at 40°C to 50°C, after fully dissolving, add 4g of acrylic acid and 0.4g of mercaptoacetic acid, stir evenly and then heat up to 80°C. 15 g of ammonium persulfate solution with a mass concentration of 2.6% was dripped into the flask through a dropping funnel. After the dropwise addition, keep the temperature at this temperature for 2 hours, then lower the temperature to 30°C, and then add NaOH solution with a mass concentration of 30% to adjust the pH of the resulting solution to 7.0 to obtain a polycarboxylate superplasticizer.

Embodiment 2

[0044] The method for preparing a polycarboxylate water reducer by combining polyether macromonomers with two structures is to add 11.0g of macromonomer A, 17.1g of macromonomer C and 55g of water into a flask at 50°C, and place the flask Put it into the oil bath of a magnetic stirrer, heat and stir at 40°C to 50°C, and after fully dissolving, add 4g of acrylic acid, 0.08g of sodium propylene sulfonate and 0.4g of mercaptoacetic acid, stir evenly and heat up to 78°C. 15 g of ammonium persulfate solution with a mass concentration of 3.0% was dropped into the flask through a dropping funnel. After the dropwise addition, keep the temperature at this temperature for 2 hours, then lower the temperature to 30°C, and then add NaOH solution with a mass concentration of 30% to adjust the pH of the resulting solution to 7.2 to obtain a polycarboxylate superplasticizer.

Embodiment 3

[0046] The method of preparing polycarboxylate water reducer by combining polyether macromonomers with two structures is to add 8.82g of macromonomer A, 13.72g of macromonomer B and 55g of water into the flask at 50°C, and place the flask Put it into the oil bath of a magnetic stirrer, heat and stir under the condition of 40℃~50℃, after fully dissolving, add 3.98g acrylic acid, 0.1g sodium propylene sulfonate, 0.06g acrylonitrile and 0.4g mercaptoacetic acid, and stir evenly The temperature was raised to 85°C. 15 g of ammonium persulfate solution with a mass concentration of 2.6% was dripped into the flask through a dropping funnel. After the dropwise addition, keep the temperature at this temperature for 2 hours, then lower the temperature to 30°C, and then add NaOH solution with a mass concentration of 30% to adjust the pH of the resulting solution to 6.8 to obtain a polycarboxylate superplasticizer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com