Thiohydroxy-modified magnetic MOFs adsorbent and preparation method and application thereof

An adsorbent and magnetic technology, applied in the field of thiol-modified magnetic MOFs adsorbent and its preparation, can solve the problems of not being particularly stable, weak interaction, poor selectivity, etc., and achieve large adsorption capacity, good stability, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

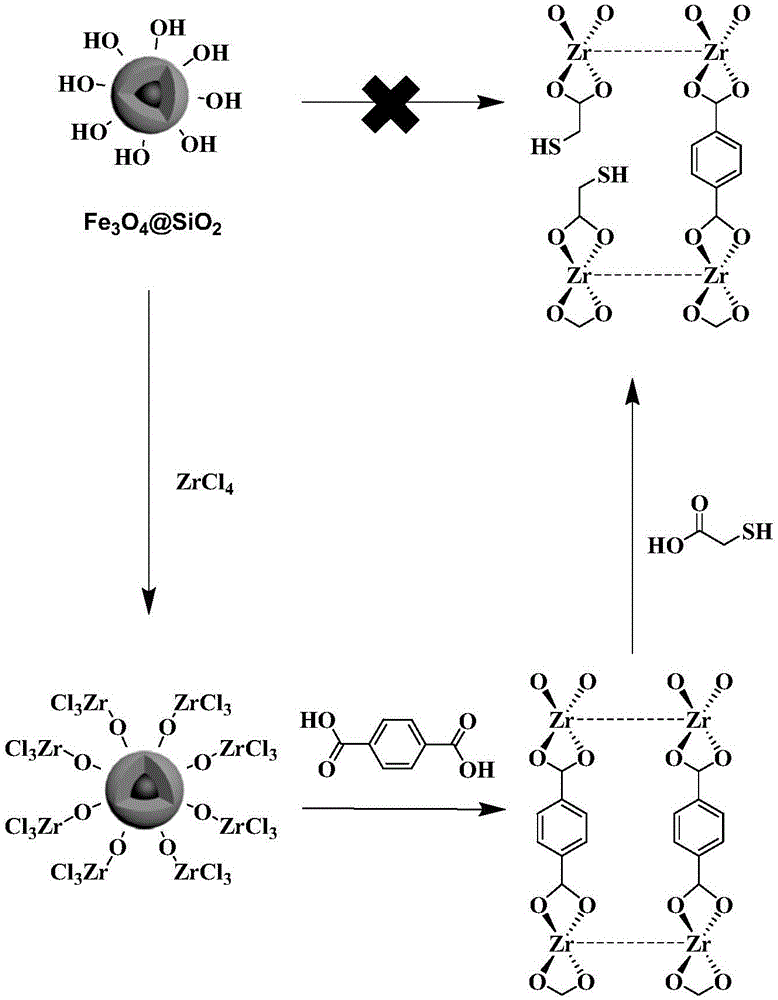

Method used

Image

Examples

Embodiment l

[0039] Preparation of Magnetic Fe with a Particle Size of 10-20nm by Co-precipitation 3 o 4 Nanospheres: Dissolve 11.68g of ferric chloride and 4.30g of ferrous chloride in 200mL of high-purity water, stir and heat to 85°C under nitrogen protection. Then add 20 mL of 30% NH 3 ·H 2 O, the color of the solution rapidly changed from orange to black. After reacting for half an hour, stop the reaction, cool to room temperature, and then wash the obtained nanoparticles with high-purity water and 0.02molL -1 washed with NaCl until neutral, and finally stored with high-purity water.

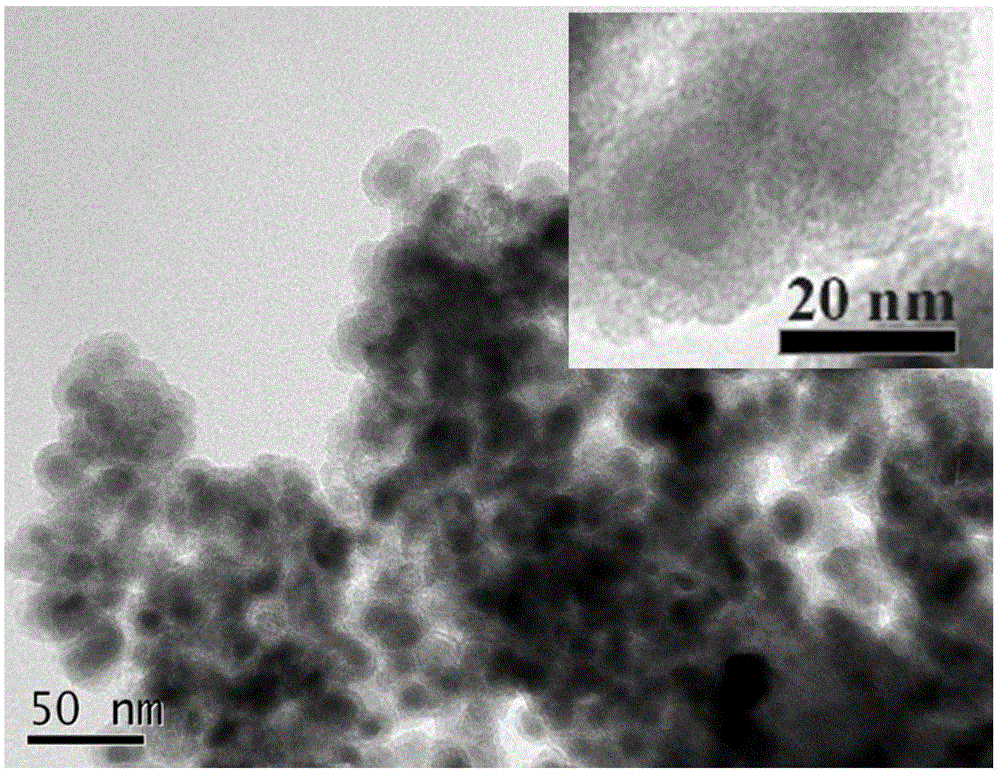

[0040] Preparation of Fe with core-shell structure by St?ber silica gel coupling method 3 o 4 SiO 2 : Remove half of the Fe 3 o 4 Put the nanoparticles into a mixed solvent containing 160mL ethanol and 40mL high-purity water, and add 5mL of 30% NH 3 ·H 2 O and 6 mL of tetraethoxysilane (TEOS), then mechanically stirred at room temperature for 12 h. After the reaction, wash with high-purity wa...

Embodiment 2

[0045] The difference from Example 1 is: Synthesis of MFC-S-2: Disperse 2 mmol of mercaptoglycolic acid in water, add KOH to adjust the pH to 7, then add 400 mg of activated MFC-O, let stand, and heat under the protection of Ar gas to 40 o C, kept for 40 hours; then washed with water and methanol in sequence, and dried at room temperature to obtain the mercapto-modified magnetic MOFs adsorbent MFC-S-2.

Embodiment 3

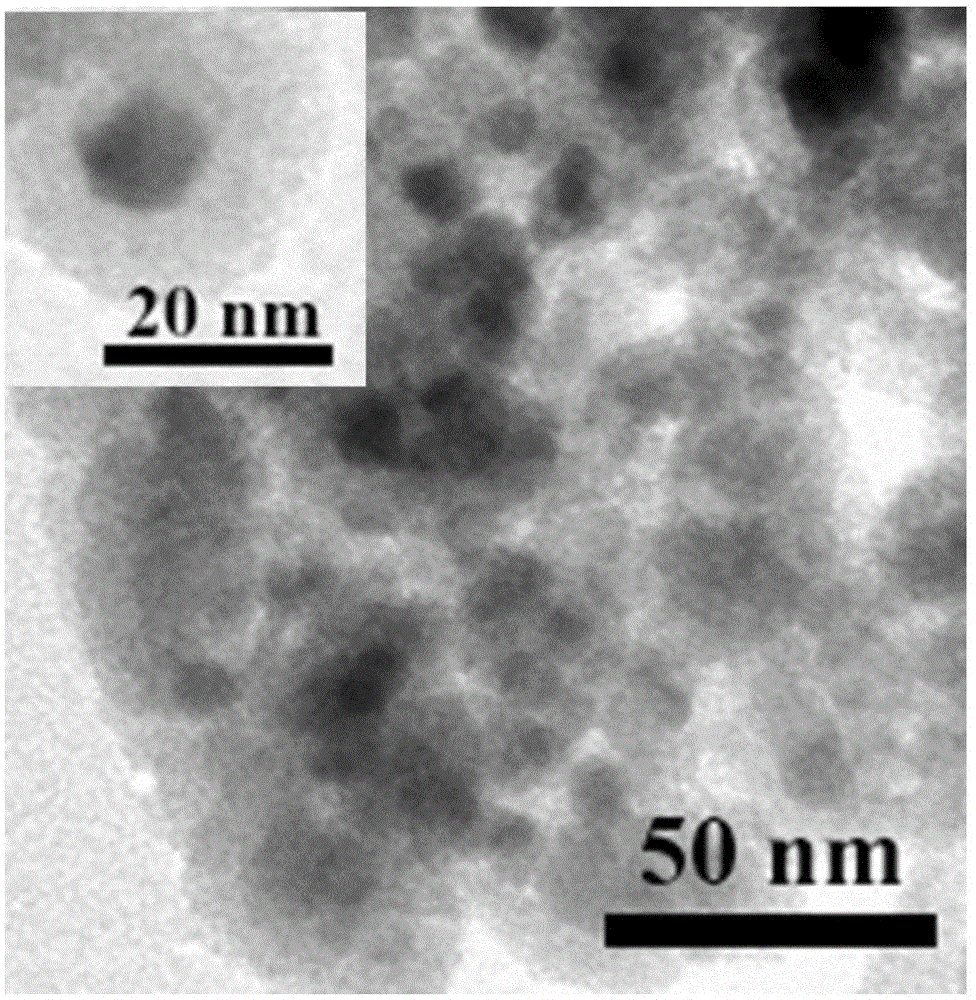

[0047] The difference from Example 1 is: Synthesis of MFC-S-3: Disperse 3 mmol of mercaptoglycolic acid in water, add KOH to adjust the pH to 7, then add 400 mg of activated MFC-O, let stand, and heat under the protection of Ar gas to 25 o C, kept for 72 hours; then washed with water and methanol in sequence, and dried at room temperature to obtain the mercapto-modified magnetic MOFs adsorbent MFC-S-3. Its TEM see image 3 , see SEM Figure 4 , FT-IR see Figure 5 , see XRD Image 6 , magnetic properties see Figure 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com