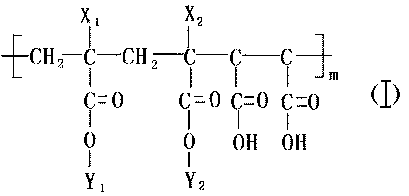

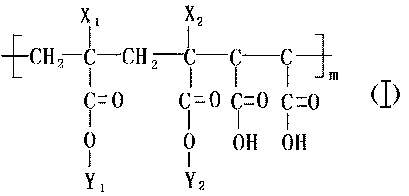

Hyperdispersant and preparation method thereof

A hyperdispersant and initiator technology, applied in chemical instruments and methods, transportation and packaging, dissolution, etc., can solve the problems of non-conforming to green production and weak dispersing ability of hyperdispersant, and achieve low cost and short production cycle The effect of short, simple synthesis preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation method of hyperdispersant in the present invention is: add acrylic acid, methacrylic acid and maleic anhydride in the reactor that distilled water is housed in advance, and add initiator, chain transfer agent and reaction monomer and stir, various raw materials wherein The weight ratio of , additive and solvent is: 60 parts of acrylic acid, 50 parts of methacrylic acid, 30 parts of maleic anhydride, 1 part of redox initiator composed of ammonium persulfate and potassium sulfite, 0.5 part of ethanol, and 150 parts of distilled water. Control the reaction temperature to 60°C, the stirring speed to 500r / min, and the reaction time to 4h, then cool to 40°C; add 35 parts of NaOH to the cooled reaction solution, and react for 1h to obtain the finished hyperdispersant. , The solid content of the resulting hyperdispersant finished product is 60%.

Embodiment 2

[0019] The preparation method of hyperdispersant in the present invention is: add acrylic acid, methacrylic acid and maleic anhydride in the reactor that distilled water is housed in advance, and add initiator, chain transfer agent and reaction monomer and stir, various raw materials wherein , the content of additives and solvents are: 40 parts of acrylic acid, 30 parts of methacrylic acid, 20 parts of maleic anhydride, 0.8 parts of a redox initiator composed of ammonium persulfate and potassium sulfite, 0.2 parts of ethanol, and 150 parts of distilled water. Control the reaction temperature to 30°C, the stirring speed to 300r / min, and the reaction time to 3h, then cool to 30°C; add 20 parts of NaOH to the cooled reaction solution, and react for 1h to obtain the finished product of hyperdispersant, after inspection , The solid content of the resulting hyperdispersant finished product is 40%.

Embodiment 3

[0021] The preparation method of hyperdispersant in the present invention is: add acrylic acid, methacrylic acid and maleic anhydride in the reactor that distilled water is housed in advance, and add initiator, chain transfer agent and reaction monomer and stir, various raw materials wherein , the content of additives and solvents are: 70 parts of acrylic acid, 60 parts of methacrylic acid, 40 parts of maleic anhydride, 1.2 parts of redox initiator composed of ammonium persulfate and potassium sulfite, 0.7 part of ethanol, and 150 parts of distilled water. Control the reaction temperature to 80°C, the stirring speed to 600r / min, and the reaction time to 5h, then cool to 50°C; add 50 parts of NaOH to the cooled reaction solution, and react for 1h to obtain the finished hyperdispersant. , The solid content of the resulting hyperdispersant finished product is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com