Composite solvent system for production process of hydrogen peroxide by anthraquinone method

An anthraquinone method hydrogen peroxide, production process technology, applied in the directions of peroxide/peroxyhydrate/peroxyacid/superoxide/ozone, inorganic chemistry, chemical instruments and methods, etc., can solve the solvent market Problems such as high price and difficulty in solvent production can achieve the effect of improving surface tension characteristics, increasing solubility, and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

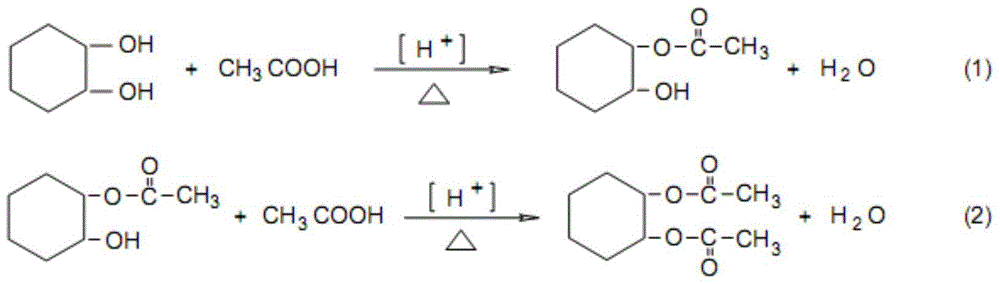

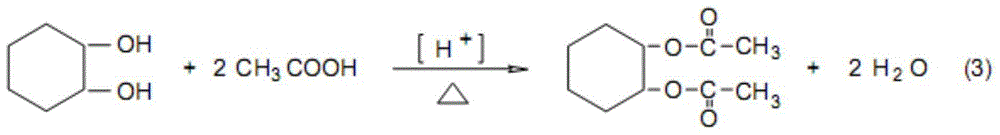

[0044] A preparation method for trans-1,2-cyclohexanediol diacetate, comprising the following steps:

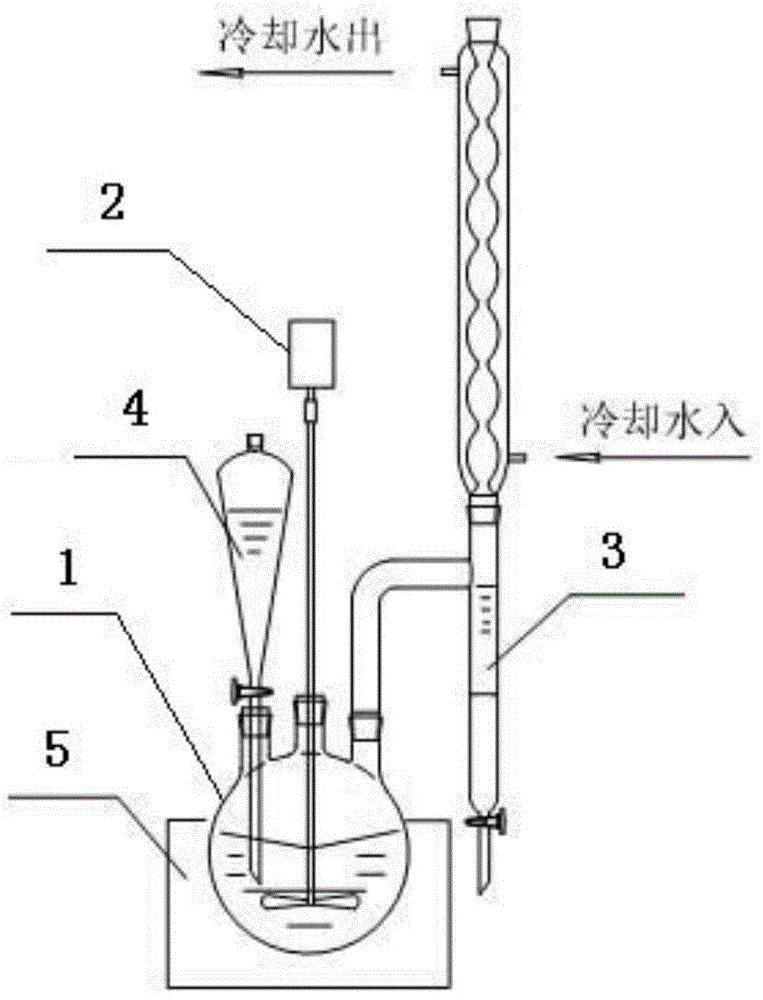

[0045] (1) if figure 1 Shown, in the 1000ml four-necked flask 1 that has mechanical stirrer 2 and reflux separator 3 (the opening that has thermometer is in figure 1 116 g (1 mol) of a sample of trans-1,2-cyclohexanediol and 8.0 g of esterification catalyst p-toluenesulfonic acid were added, and then 200 g of reaction solvent methylcyclohexane was added. The four-necked flask 1 was placed in an electric heating mantle 5 to heat up to completely dissolve the trans-1,2-cyclohexanediol and the esterification catalyst.

[0046] In this example, trans-1,2-cyclohexanediol is obtained by hydrolysis reaction of epoxycyclohexane recovered from the by-product light oil in the production process of cyclohexanone under acidic conditions; the hydrolysis reaction The post-treatment of liquid includes stratification, neutralization, concentration, crystallization and centrifugal separatio...

Embodiment 2

[0053] A kind of complex type solvent system for the anthraquinone method hydrogen peroxide production technique of the present invention, comprises heavy aromatic hydrocarbon (usually C 9 ~C 10 Heavy aromatics), trioctyl phosphate, isooctyl acetate and trans-1,2-cyclohexanediol diacetate, wherein trans-1,2-cyclohexanediol diacetate is obtained from Example 1 method prepared. The ratio of each component in the composite solvent system of this embodiment is (mass percentage) heavy aromatic hydrocarbon: trioctyl phosphate: isooctyl acetate: trans-1,2-cyclohexanediol diacetate=63%: 23 %: 7%: 7%. In the present invention, each component can be implemented within the following preferred ranges: 60% to 65% of heavy aromatics, 20% to 25% of trioctyl phosphate, 6% to 8% of isooctyl acetate, trans- The content of 1,2-cyclohexanediol diacetate is 6%-8%, and the mass ratio of isooctyl acetate to trans-1,2-cyclohexanediol diacetate is more preferably 1:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| solubility (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com