Visible-light response magnetic compound photocatalytic material and preparation method thereof

A composite photocatalysis and visible light technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve problems such as damage and strong corrosion, and achieve magnetic properties. Excellent, simple recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of a magnetic composite photocatalytic material responsive to visible light, the specific synthesis steps are as follows:

[0030] (1) Thioglycolic acid modified Fe 3 o 4 Preparation of:

[0031] 1.35g ferric chloride (Fe 3 Cl 3 ·6H 2 O) Dissolve in 40mL of ethylene glycol to form a clear liquid, then weigh 3.6g of anhydrous sodium acetate and 1.0g of polyethylene glycol into the ferric chloride solution, stir and dissolve, transfer to a high-pressure reactor, and store at 200°C The reaction product was separated by a magnet for 8 hours, washed 5 times with absolute ethanol and deionized water, and dried in vacuum at 60°C for 8 hours to obtain Fe 3 o 4 Magnetic nanoparticles; 0.1g Fe 3 o 4 The magnetic nanoparticles were added to 20 mL of ethanol solution of thioglycolic acid (0.29 mM) and stirred for 24 hours. The product was separated by a magnet, washed alternately with deionized water and absolute ethanol four times, and dried at 60 °C for 9 ...

Embodiment 2

[0037] The preparation of MIL-101 (Cr) material is as described in Example 1 step (2), except that Fe is not added 3 o 4 Nanoparticles.

[0038] Figure 1~5 It is the XRD, XPS, TEM, UV-VisDRS characterization diagram and the effect diagram of RhB degradation according to each sample in Examples 1-2 of the present invention.

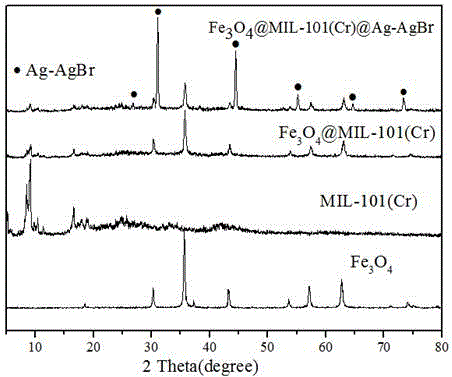

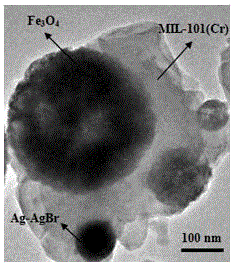

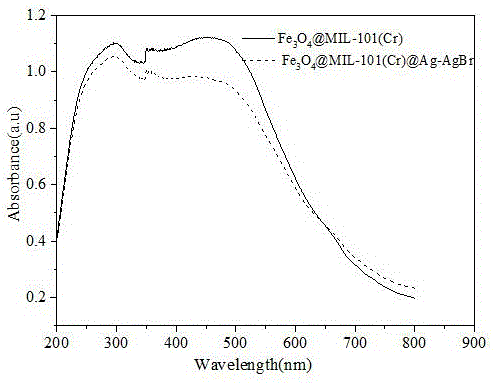

[0039] Depend on figure 1 It can be seen that the prepared Fe 3 o 4 The XRD pattern of MIL-101(Cr) has both Fe 3 o 4 and the characteristic peaks of MIL-101(Cr), indicating that our alkaline condition can successfully synthesize the magnetic metal-organic framework material Fe 3 o 4 MIL-101(Cr), the hydrothermal process will not cause Fe 3 o 4 Crystal destruction. At the same time, Fe 3 o 4 The XRD pattern of MIL-101(Cr)Ag-AgBr has Fe 3 o 4 , MIL-101(Cr) and Ag-AgBr three characteristic peaks, indicating that Fe 3 o 4 The MIL-101(Cr)Ag-AgBr composite material is composed of these three materials, and the loading process of Ag-AgBr did not...

Embodiment 3

[0045] Respectively, the preparation method of the magnetic composite photocatalytic material responsive to visible light, the steps are basically the same as in the examples, the difference is that in step (2) Fe 3 o 4 It is 0.116g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com