Acid-resistant magnetic chitosan microspheres as well as preparation method and application thereof

A technology of chitosan microspheres and acid resistance, which is applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., to achieve the effect of improving acid resistance and strong acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

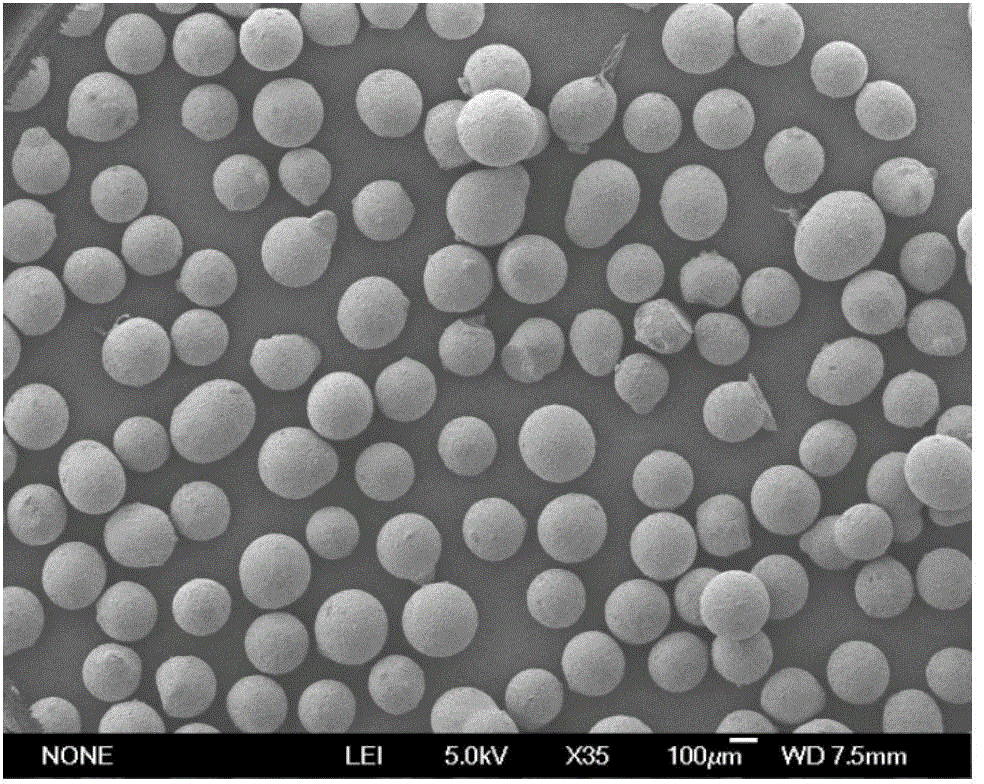

[0055] The preparation of magnetic chitosan microspheres, the preparation steps are:

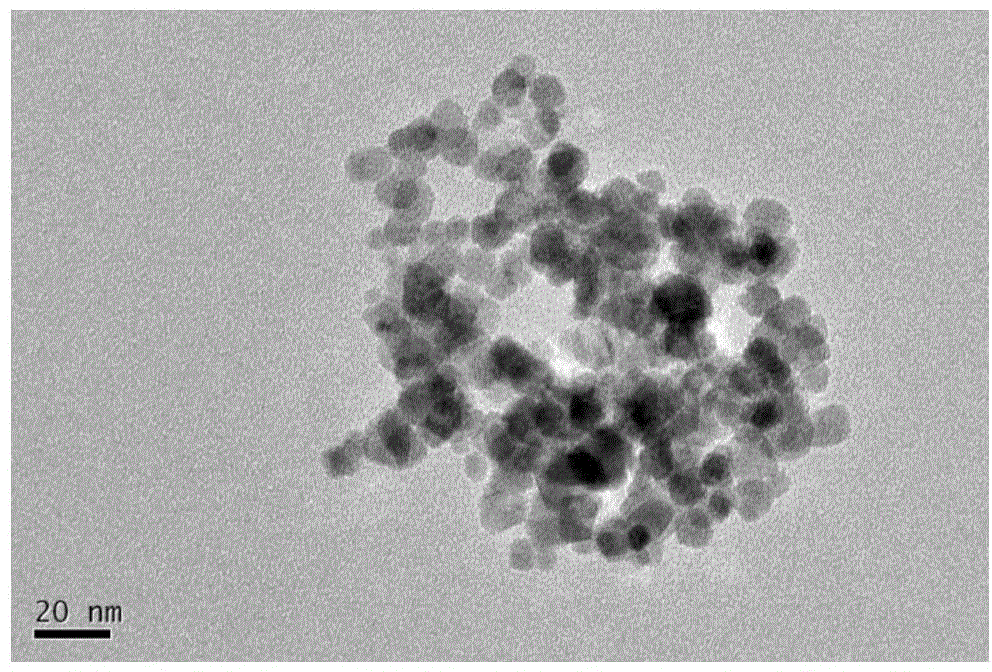

[0056] Add 10mmol ferric trichloride and 5mmol ferric dichloride to a stirred reactor filled with 100mL distilled water, raise the temperature to 60°C under the protection of nitrogen, then add 25mL concentrated ammonia water under high-speed stirring conditions, and the solution will turn black quickly Add 0.2mmol sodium citrate and continue the constant temperature reaction for 20min. The product was separated and recovered with a magnet, washed several times with deionized water and stored in water.

[0057] Take 0.1g of citric acid modified Fe 3 o 4 Nanoparticles were ultrasonically dispersed into a mixed solution consisting of 40mL ethanol and 1.2mL concentrated ammonia water. Under continuous mechanical stirring, 0.4mL tetraethyl orthosilicate was slowly added, and the reaction was stirred at room temperature for 12h. After the reaction, it was magnetically separated, washed repeate...

Embodiment 2

[0060] The preparation of magnetic chitosan microspheres, the preparation steps are:

[0061]Add 50mmol ferric trichloride and 25mmol ferric dichloride to a stirred reactor filled with 100mL distilled water, raise the temperature to 90°C under the protection of nitrogen, then add 25mL concentrated ammonia water under high-speed stirring conditions, and the solution will turn black quickly 2mmol sodium citrate was added, and the constant temperature reaction was continued for 60min. The product was separated and recovered with a magnet, washed several times with deionized water and stored in water.

[0062] Take 0.1g of citric acid modified Fe 3 o 4 Nanoparticles were ultrasonically dispersed into a mixed solution consisting of 80mL ethanol and 2.4mL concentrated ammonia water. Under continuous mechanical stirring, 0.8mL tetraethyl orthosilicate was slowly added, and the reaction was stirred at room temperature for 24h. After the reaction, it was magnetically separated, wash...

Embodiment 3

[0065] The preparation of magnetic chitosan microspheres, the preparation steps are:

[0066] Add 10mmol ferric trichloride and 5mmol ferric dichloride to a stirred reactor filled with 100mL distilled water, raise the temperature to 60°C under the protection of nitrogen, then add 25mL concentrated ammonia water under high-speed stirring conditions, and the solution will turn black quickly Add 0.2mmol sodium citrate and continue the constant temperature reaction for 20min. The product was separated and recovered with a magnet, washed several times with deionized water and stored in water.

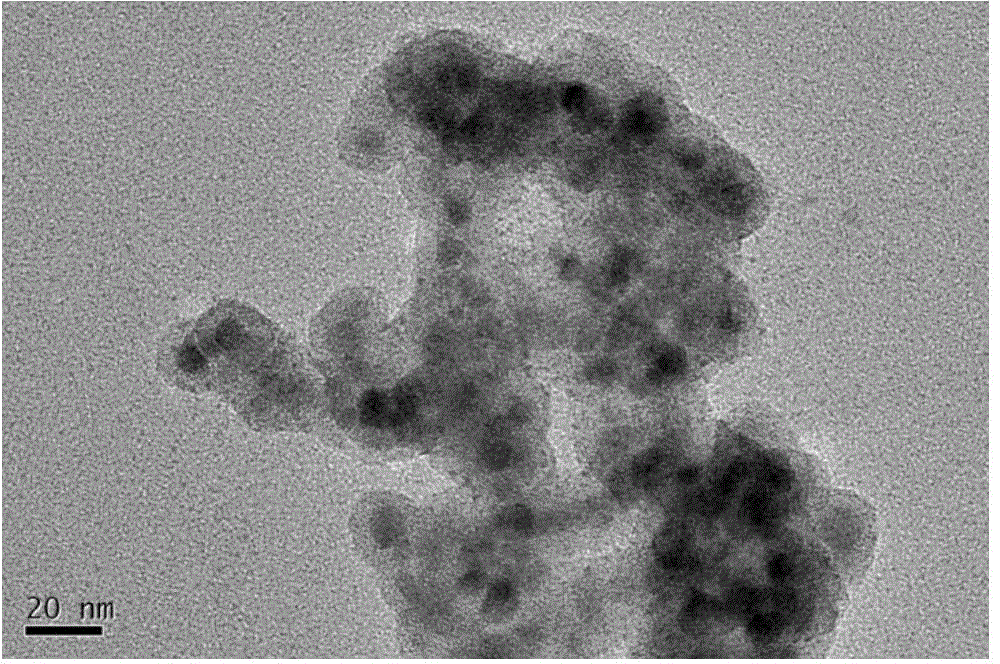

[0067] Take 0.1g of citric acid modified Fe 3 o 4 Nanoparticles were ultrasonically dispersed into 50mL aqueous solution containing 0.475g sodium silicate, the temperature of the solution was raised to 85°C, and under high-speed stirring conditions, hydrochloric acid with a concentration of 2mol / L was added dropwise to the solution, and the pH value of the solution changed from alkali to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com