Preparation method of fluorescent submicron particle/complex multicolor fluorescent fibers

A fluorescent fiber and sub-micron technology, applied in fiber processing, fiber chemical characteristics, chemical instruments and methods, etc., can solve the problems of wide fluorescent color distribution, uneven fluorescent fiber color, easy quenching, etc., and achieve narrow fluorescent color distribution , good stability and size controllable, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

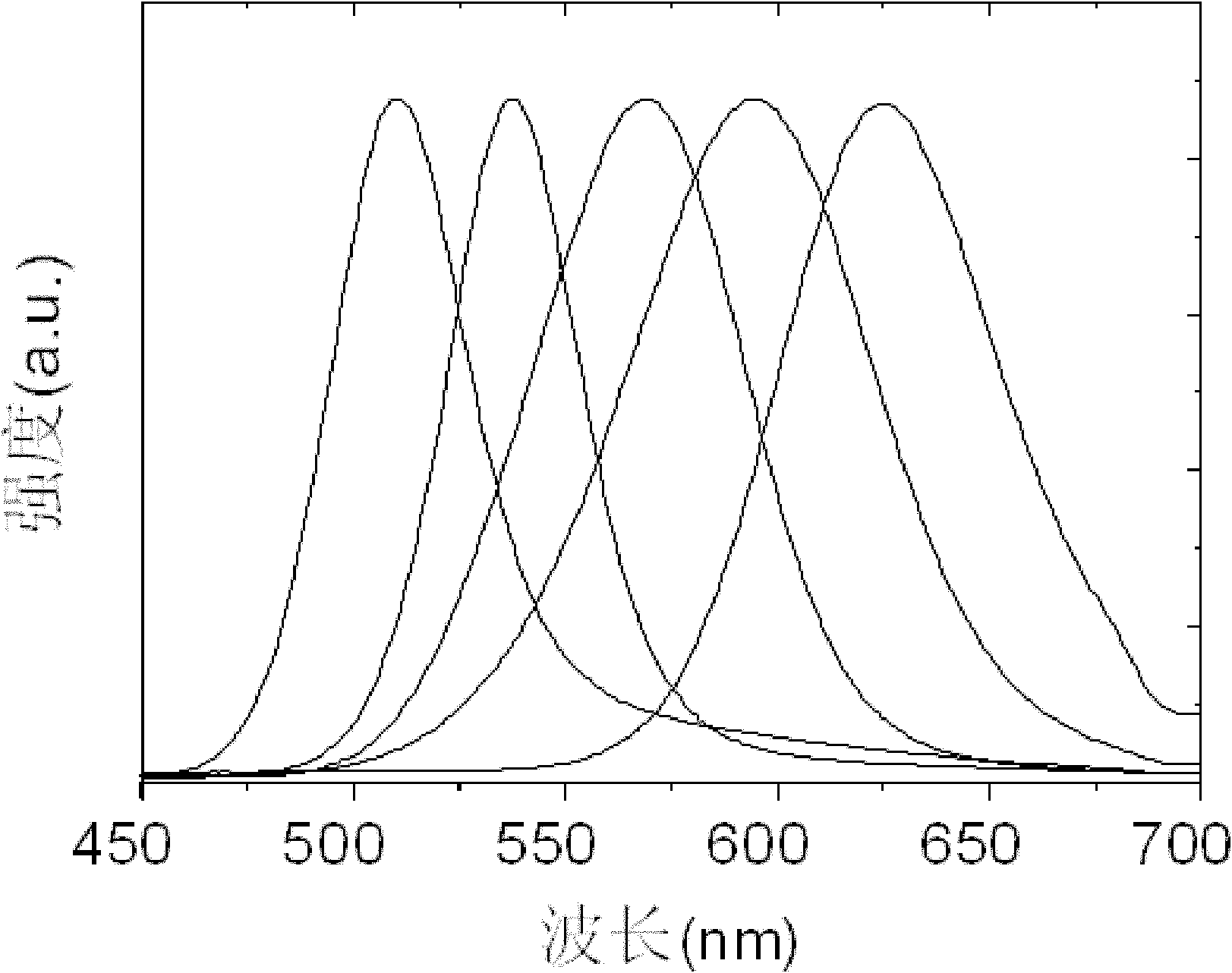

[0017] Specific embodiment 1: The preparation method of fluorescent submicron particles / composite colorful fluorescent fibers in this embodiment is realized through the following steps: 1. Mix 100mL ultrapure water, 91.3mgCdCl 2 2.5H 2 0 and 0.0617mL mercaptoacetic acid are added in the three-necked flask, then NaOH solution is added dropwise in the three-necked flask under agitation, until the pH value is 11, then adding 6mL mass concentration is 2% NaHTe aqueous solution to obtain the reaction solution, then Heating to 100°C under nitrogen, reflux for 10min, 1h, 2h, 3h or 4h, to obtain CdTe quantum dot suspension;

[0018] 2. Add 0.25mL tetraethyl orthosilicate, 20.55mL ethanol, 9mLH to the CdTe quantum dot suspension obtained in step 1 2 The concentration of O and 0.2mL is 28% (mass) ammonia water, stirring and reacting for 3-5h to obtain SiO 2 Coated CdTe quantum dot microsphere suspension, and then centrifuged to obtain SiO 2 Coated CdTe quantum dot microspheres;

[0...

specific Embodiment approach 2

[0024] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step two, SiO can also be obtained through the following steps 2 Coated CdTe quantum dot microspheres: Add 3 mL tetraethyl orthosilicate, 25 mL ethanol, 0.5 mL H to the CdTe quantum dot suspension obtained in step 1 2 The concentration of O and 1.5mL is 28% (mass) ammonia water, stirring and reacting for 3-5h to obtain SiO 2 Coated CdTe quantum dot microsphere suspension, and then centrifuged to obtain SiO 2 Coated CdTe quantum dot microspheres. Other steps and parameters are the same as those in Embodiment 1.

[0025] The SiO obtained in Step 2 of this embodiment 2 The particle size range of the coated CdTe quantum dot microsphere is 160-360nm.

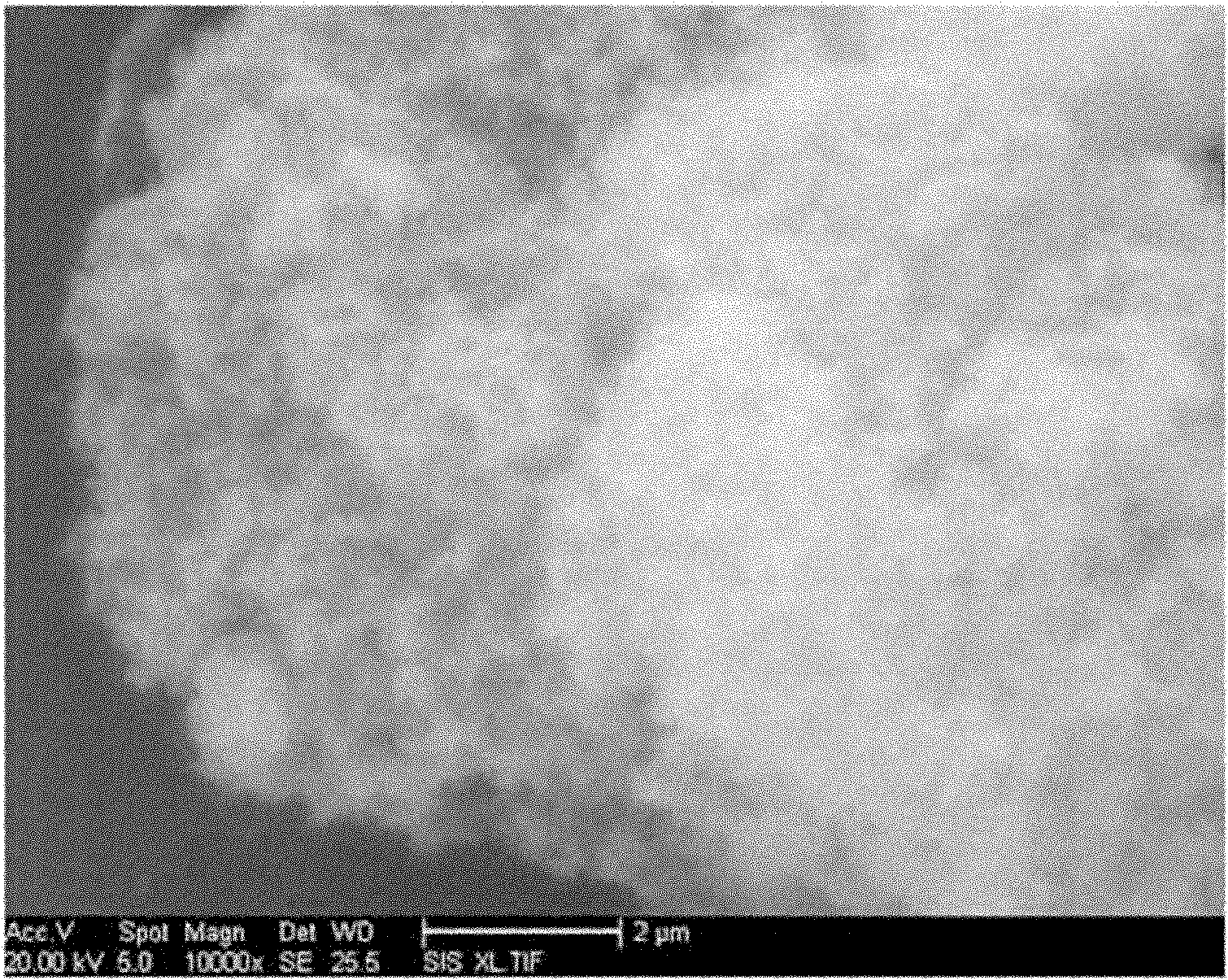

[0026] The SiO prepared in Step 2 of this embodiment 2 Scanning electron micrographs of coated CdTe quantum dot microspheres image 3 shown. One of the SiO 2 The transmission electron microscope pictures of the coated...

specific Embodiment approach 3

[0027] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step two, SiO can also be obtained through the following steps 2 Coated CdTe quantum dot microspheres: Add 1.3mL tetraethyl orthosilicate, 22.7mL ethanol, 3mL H to the CdTe quantum dot suspension obtained in step 1 2 The concentration of O and 3mL is 28% (mass) ammonia water, stir and react for 3-5h to obtain SiO 2 Coated CdTe quantum dot microsphere suspension, and then centrifuged to obtain SiO 2 Coated CdTe quantum dot microspheres. Other steps and parameters are the same as those in Embodiment 1.

[0028] The SiO obtained in Step 2 of this embodiment 2 The particle size range of the coated CdTe quantum dot microspheres is 1-2 μm.

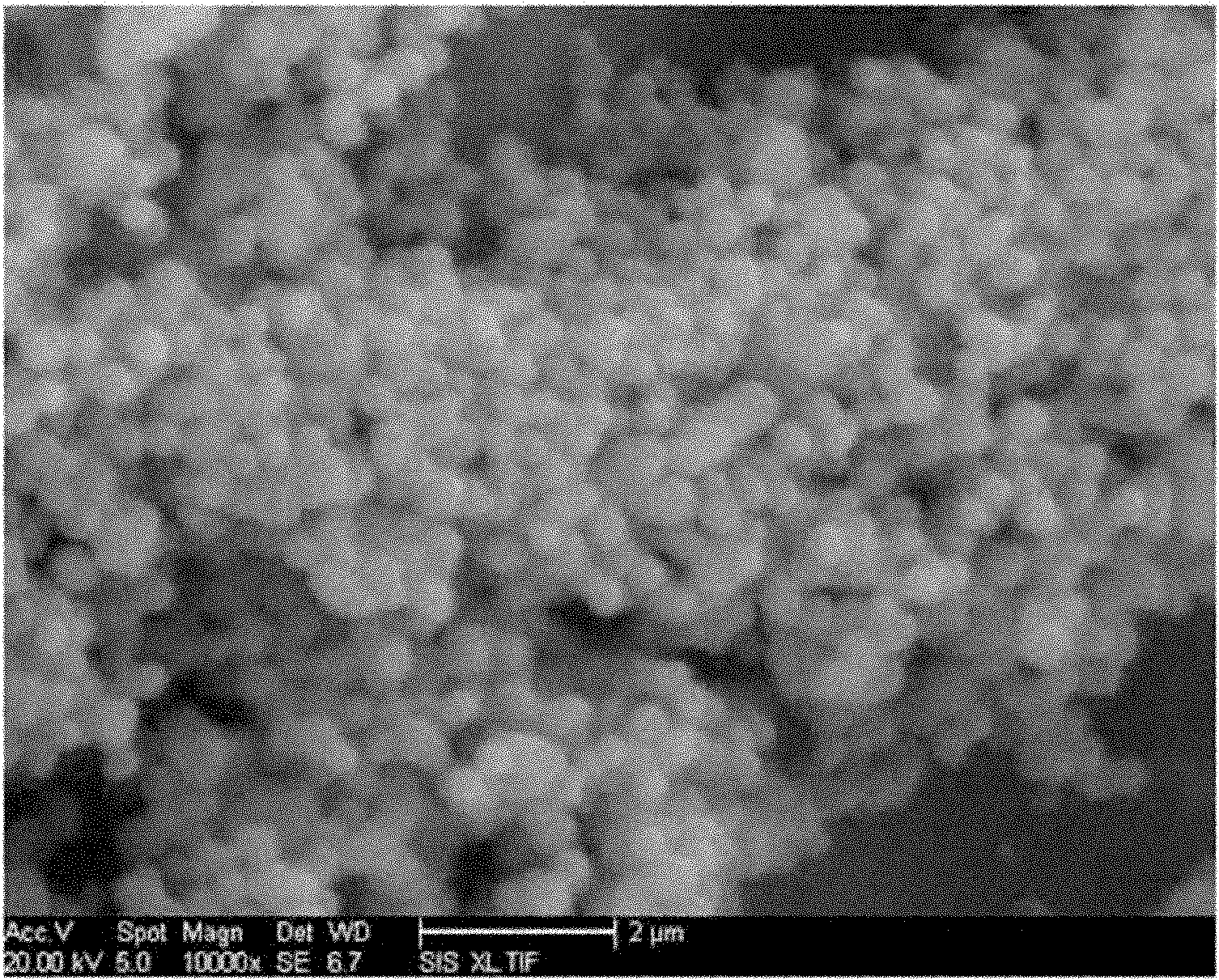

[0029] The SiO prepared in Step 2 of this embodiment 2 Scanning electron micrographs of coated CdTe quantum dot microspheres Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com