Soil heavy metal passivator and preparation method thereof

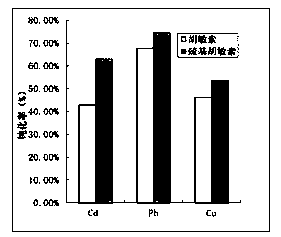

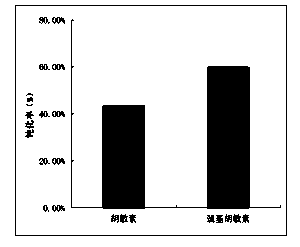

A heavy metal passivator and passivator technology, applied in chemical instruments and methods, soil conditioning materials, agriculture, etc., can solve the problem of unsatisfactory Cd passivation effect, polluted surface water and groundwater, and poor passivation effect of cadmium and other problems, to achieve the effect of novel technology, good effect and improving passivation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of a soil heavy metal deactivator, comprising the steps of:

[0030] (1) Peat soil pretreatment: air-dry the peat soil, pass through an 8-mesh nylon sieve to remove coarse fibers in the peat soil;

[0031] (2) Humin extraction: Weigh an appropriate amount of pretreated peat soil, mix it with a sodium hydroxide solution with a concentration of 0.1mol / L in a container, add 10ml of sodium hydroxide for every 1g of peat soil, and make the peat soil It was suspended in the solution and placed on a shaker for 6 hours; left to stand and centrifuged, the supernatant was taken out, and washed repeatedly with distilled water until the supernatant was light yellow; air-dried to obtain crude humin (HM );

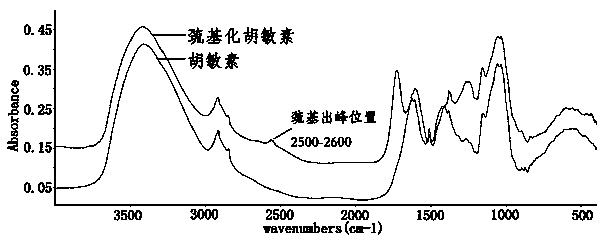

[0032] (3) Humin thiolation: mix thioglycolic acid, acetic anhydride, and acetic acid (36%) in a volume ratio of 5:3:2, add 2 to 3 drops of concentrated sulfuric acid solution with a volume fraction of 0.1% and a mass percentage of 3% crude Humin, stir and ...

Embodiment 2

[0035] A preparation method of a soil heavy metal deactivator, comprising the steps of:

[0036] (1) Peat soil pretreatment: air-dry the peat soil, pass through an 8-mesh nylon sieve to remove coarse fibers in the peat soil;

[0037] (2) Humin extraction: Weigh an appropriate amount of pretreated peat soil, mix it with a sodium hydroxide solution with a concentration of 0.1mol / L in a container, add 10ml of sodium hydroxide for every 1g of peat soil, and make the peat soil It was suspended in the solution and placed on a shaker for 8 hours; left to stand and centrifuged, the supernatant was taken out, and washed repeatedly with distilled water until the supernatant was light yellow; air-dried to obtain crude humin (HM );

[0038] (3) Humin thiolation: mix thioglycolic acid, acetic anhydride, and acetic acid (36%) in a volume ratio of 5:3:2, add 2 to 3 drops of concentrated sulfuric acid solution with a volume fraction of 0.5% and a mass percent of 5% crude Humin, stir and coo...

Embodiment 3

[0041] A preparation method of a soil heavy metal deactivator, comprising the steps of:

[0042] (1) Peat soil pretreatment: air-dry the peat soil, pass through an 8-mesh nylon sieve to remove coarse fibers in the peat soil;

[0043] (2) Humin extraction: Weigh an appropriate amount of pretreated peat soil, mix it with a sodium hydroxide solution with a concentration of 0.1mol / L in a container, add 10ml of sodium hydroxide for every 1g of peat soil, and make the peat soil It was suspended in the solution, and placed on a shaker for 7 hours; left to stand and centrifuged, the supernatant was taken out, and washed repeatedly with distilled water until the supernatant was light yellow; air-dried to obtain crude humin (HM );

[0044] (3) Humin thiolation: Mix thioglycolic acid, acetic anhydride, and acetic acid (36%) in a volume ratio of 5:3:2, add 2 to 3 drops of concentrated sulfuric acid solution with a volume fraction of 0.3% and 4% crude humin, and stir Cool to room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com